A kind of polymer film with improved antifouling performance and preparation method thereof

A technology for polymer membranes and antifouling performance, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problem of insoluble zwitterionic polymers, achieve the ability to inhibit easy agglomeration, and have obvious antifouling performance , The effect of antifouling performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

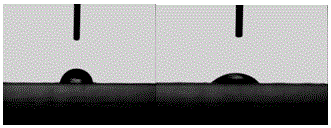

[0069] Preparation of PVDF Flat Membrane with Antifouling Function

[0070] 1. Preparation of modified nanoparticles

[0071]Disperse 1 g of hydrophilic silica nanoparticles into 100 g of water with pH 6 by ultrasonic, add 0.05 g of epoxy silane coupling agent KH560, and react at 95 °C for 8 hours; then add 0.08 g of lysine. amino acid, and the reaction was continued at 95 °C for 2 hours. After the reaction is completed, centrifuge to collect the modified nanoparticles for use.

[0072] see figure 1 The IR spectrum shown, the silica nanoparticles have been surface-modified with lysine, and the IR spectrum is at 1518 cm -1 and 1410 cm -1 There are new peaks at the N-H vibration of the amino group and the symmetric stretching vibration of the carboxylic acid group, indicating that the surface of the silica nanoparticles has been successfully grafted with lysine, and the surface zwitterion of the nanoparticles has been realized.

[0073] 2. Preparation of polymer films

...

Embodiment 2

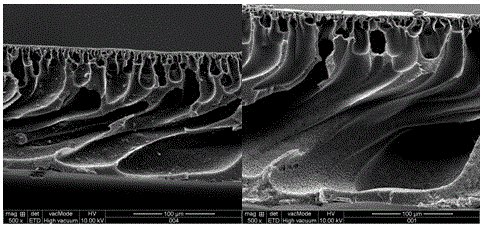

[0084] Preparation of PVDF hollow fiber membrane with antifouling function

[0085] 1. Preparation of modified nanoparticles

[0086] Disperse 1 g of hydrophilic silica nanoparticles into 100 g of water with a pH value of 5 by ultrasonication, add 0.2 g of KH560, and react at 95 °C for 10 hours; then add 0.3 g of lysine, and continue at 95 °C. reaction for 3 hours. After the reaction is completed, centrifuge to collect the modified nanoparticles for use.

[0087] 2. Preparation of polymer films

[0088] 0.05 g of modified silica nanoparticles and 0.5 g of PVP were ultrasonically dispersed into 60 g of NMP by ultrasonic at 100-1000 W power, and then 10 g of PVDF was added to obtain a casting solution; After the vacuum defoaming treatment, put it into the spinning kettle, and extruded from the spinneret composed of two concentric tubes under the spinning speed of 10 r / min and the spinning pressure of 0.5 MPa by the metering pump; In the spinning process, the extruded fiber...

Embodiment 3

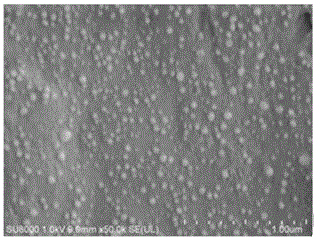

[0096] Preparation of PES Flat Film with Antifouling Function

[0097] 1. Preparation of modified nanoparticles

[0098] 1 g of titanium dioxide nanoparticles were ultrasonically dispersed into 100 g of water with a pH value of 6, 0.5 g of epoxy silane coupling agent KH560 was added, and the reaction was carried out at 95 °C for 12 hours; then 1 g of lysine was added, and the reaction was continued at 95 The reaction was carried out at °C for 6 hours. After the reaction is completed, centrifuge to collect the modified nanoparticles for use.

[0099] 2. Preparation of polymer films

[0100] 1 g of modified titanium dioxide nanoparticles were ultrasonically dispersed into 50 g of DMF, then 10 g of PES and 0.5 g of PEG were added, and the casting solution was prepared by stirring and dissolving for 40 min with a high-speed mechanical stirrer at a speed of 10,000 r / min; After 6 hours of vacuum defoaming treatment of the casting solution, the casting solution was directly scra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com