CuCrO2/TiO2 composite photocatalyst and preparation method thereof

A technology of catalyst and composite light, which is applied in the field of photocatalysis, can solve the problems of catalyst fixation and recovery difficulties, and achieve the effect of solving catalyst solidification, improving photocatalytic efficiency, and promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] CuCrO was dispersed by ultrasonic dispersion 2 Nanocrystals (10-20nm) are uniformly dispersed in absolute ethanol, and configured as a dispersion with a concentration of 0.10g / L, and TiO 2 The nanorod array film (6 μm) was used as the substrate, and the composite photocatalyst was prepared by spin-coating method: use a pipette to take 0.15 mL of CuCrO 2 The dispersion liquid is uniformly drip-coated on the film substrate, and spin-coated at 1000 rpm for 20 seconds. After the sample is naturally dried, the next spin-coating is performed until the spin-coating is completed 15 times. Then put the sample in a muffle furnace, heat treatment at 500°C for 5 hours under the protection of Ar atmosphere at a heating rate of 5°C / min, and then cool with the furnace to obtain CuCrO 2 / TiO 2 composite photocatalyst.

[0025] The photocatalyst performance test was carried out on the photocatalyst prepared in this example. The specific process was as follows: select methylene blue (...

Embodiment 2

[0027] CuCrO was dispersed by ultrasonic dispersion 2 Nanocrystals (10-20nm) are uniformly dispersed in absolute ethanol, and configured as a dispersion with a concentration of 0.50g / L, and TiO 2 The nanorod array film (2 μm) was used as the substrate, and the composite catalyst was prepared by spin-coating method: use a pipette to take 0.15 mL of CuCrO 2 The dispersion liquid is uniformly drip-coated on the film substrate, and spin-coated at a speed of 5000 rpm for 20 seconds. After the sample is naturally dried, the next spin-coating is performed until the spin-coating is completed 5 times. Then put the sample in a muffle furnace, heat treatment at 500°C for 1 hour under the protection of Ar atmosphere at a heating rate of 5°C / min, and then cool with the furnace to obtain CuCrO 2 / TiO 2 composite photocatalyst.

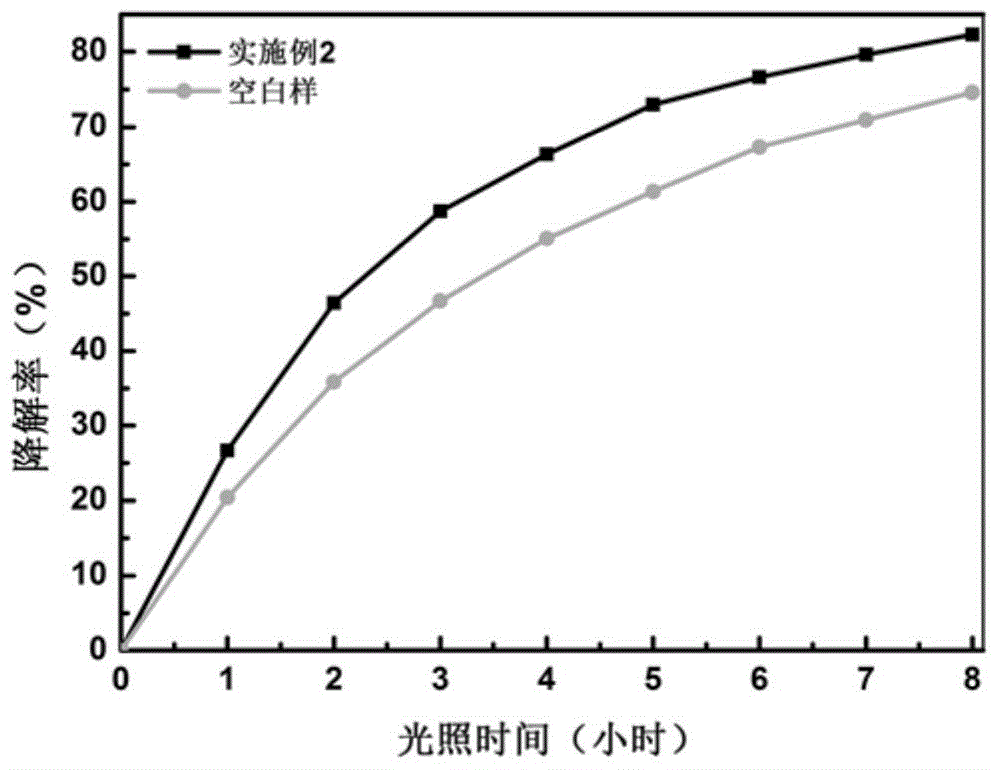

[0028] Such as figure 1 Shown is the CuCrO prepared by this embodiment 2 / TiO 2 Composite photocatalyst and blank sample (TiO 2 Nanorod array film) compariso...

Embodiment 3

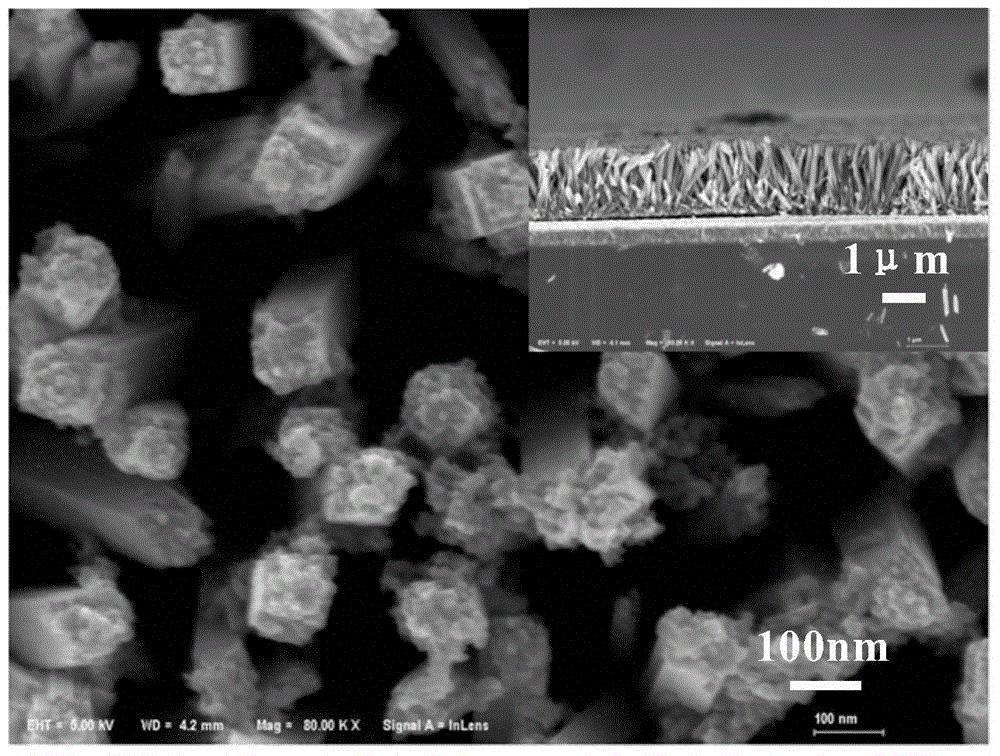

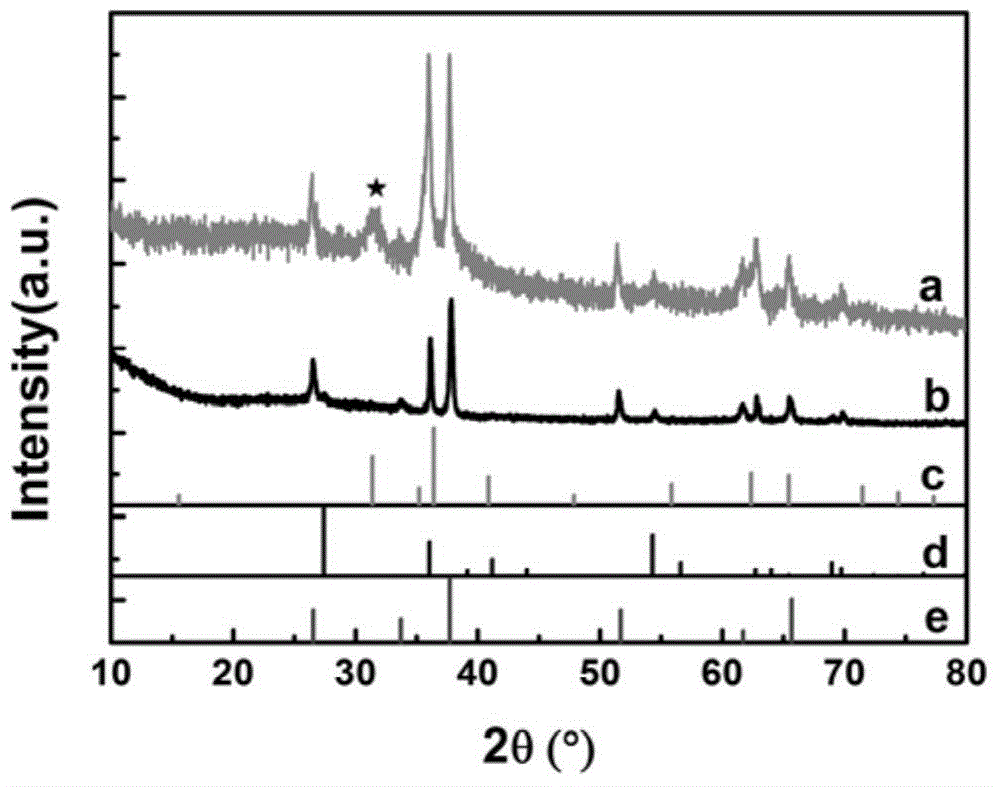

[0030] CuCrO was dispersed by ultrasonic dispersion 2 Nanocrystals (10-20nm) are uniformly dispersed in absolute ethanol, and configured as a dispersion with a concentration of 1.0g / L, and TiO 2 The nanorod array film (2 μm) was used as the substrate, and the composite catalyst was prepared by spin-coating method: use a pipette to take 0.15 mL of CuCrO 2 The dispersion liquid is uniformly drip-coated on the film substrate, and spin-coated at a speed of 5000 rpm for 20 seconds. After the sample is naturally dried, the next spin-coating is performed until the spin-coating is completed 5 times. Then the spin-coated sample was placed in a muffle furnace, heat-treated at 300°C for 1 hour at a heating rate of 5°C / min, and then cooled with the furnace to obtain CuCrO 2 / TiO 2 composite photocatalyst. Its photocatalytic performance was characterized, and its 8h degradation rate was 81.1%. Such as figure 2 Shown is the CuCrO prepared in this embodiment 2 / TiO 2 The field emissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com