Fog collection composite material and preparation method thereof

A composite material and mist technology, applied in hydrophobic materials and hydrophilic fields, can solve the problems of ineffective adjustment of spacing, high synthesis cost, and difficulty in obtaining large-area mist collecting materials, so as to increase etching time and increase etching effect. , Improve the effect of etching power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] (2) A preparation method of mist collection composite material

[0046] Such as Figure 1 to Figure 11 Shown, a kind of mist collection composite material and preparation method thereof, comprises the following steps:

[0047] In step one, a silicon dioxide single-layer colloidal sphere crystal array composed of closely contacting silicon dioxide microspheres is synthesized on a polydimethylsiloxane substrate by a self-organization method.

[0048] Specifically, this step may specifically include the following specific implementations:

[0049] (1) The thickness of the polydimethylsiloxane base is preferably 10 microns to 5 mm. If the thickness of the polydimethylsiloxane base is too large, it is not economical; if the polydimethylsiloxane If the thickness of the alkyl base is too small, the dimethylsiloxane base may be etched through the pit during the etching process of step 2; in practical applications, the polydimethylsiloxane base is the best The in-situ polymer...

Embodiment 1

[0058] Such as Figure 1 to Figure 11 Shown, a kind of mist collection composite material and preparation method thereof, comprises the following steps:

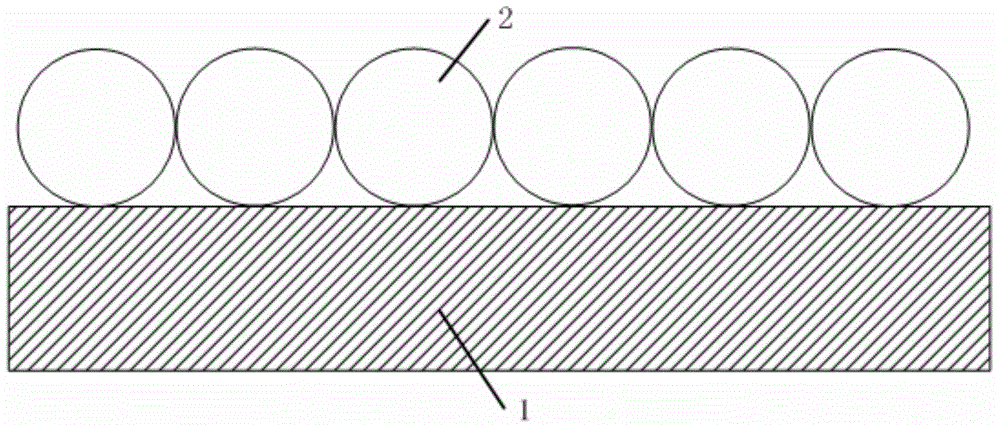

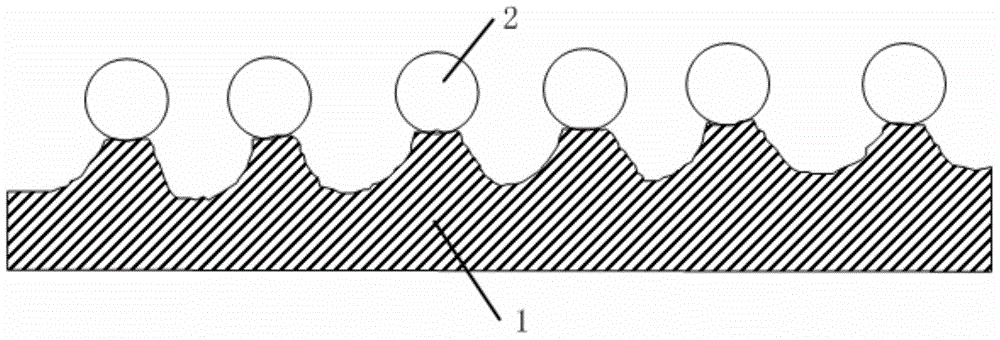

[0059] Step 1, using a self-organization method to synthesize a large-area hexagonally arranged and closely contacted silicon dioxide microsphere 2 array on a polydimethylsiloxane substrate 1 . Wherein, the thickness of the polydimethylsiloxane substrate 1 is 250 microns, and the diameter of the silica microspheres 2 obtained in Step 1 is 5.0 microns.

[0060] Step 2, using carbon tetrafluoride as the reaction gas, and using the reactive ion etching method to etch the polydimethylsiloxane substrate 1 attached with the silicon dioxide microspheres 2; after the etching process is completed, That is, a mist-collecting composite material in which superhydrophobic-superhydrophilic units are spaced apart from each other is obtained.

[0061] Wherein, the flow rate of carbon tetrafluoride is 30 ml / min, the etching power is 50 wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com