Cuprous oxide nano microspheres in double-layered structure and preparation method thereof

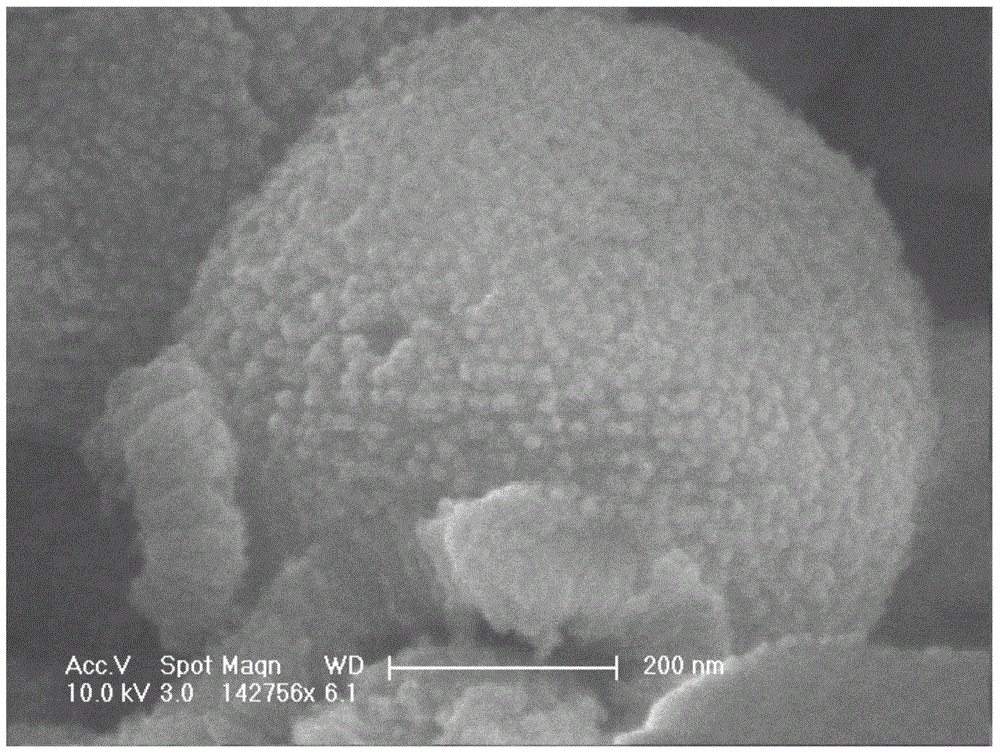

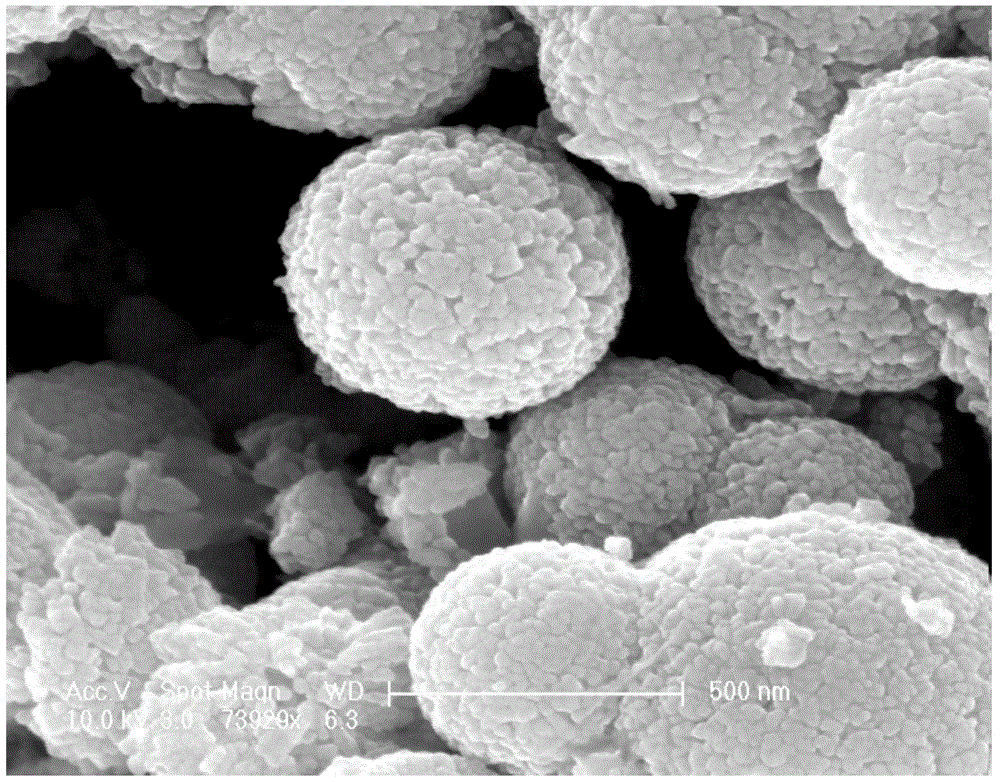

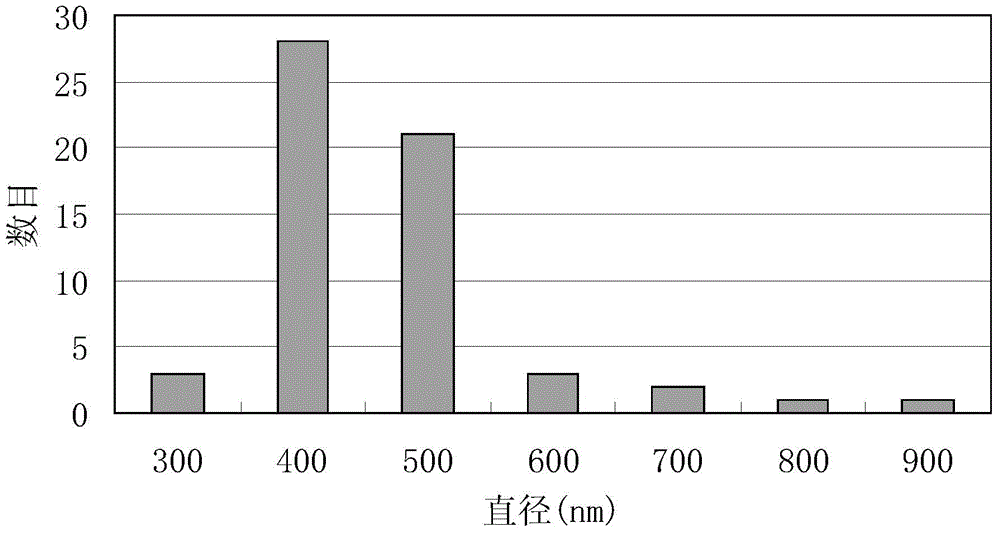

A technology of cuprous oxide and nano-microspheres, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of large diameter and small specific surface area of cuprous oxide nanomaterials, and achieve regular surface morphology , large specific surface area and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another aspect of the present invention provides a method for preparing the double-layer structure nano-cuprous oxide of the first aspect of the present invention, comprising the following steps:

[0047] Step (1), dissolving the copper salt in water to obtain an aqueous copper salt solution; dissolving sodium oleate in ethanol to obtain an ethanol solution of sodium oleate;

[0048] Step (2), adding the aqueous copper salt solution and the ethanol solution of sodium oleate obtained in step (1) into a reaction vessel, stirring for 5-10 minutes, and then adding an aqueous solution of hydrazine hydrate dropwise to the reaction system;

[0049] Step (3), after the hydrazine hydrate aqueous solution is added dropwise, stirring and reacting at 20-30°C for 5-10 minutes;

[0050] Step (4), after the reaction, centrifuge the obtained reaction solution, remove the supernatant, add ethanol and perform ultrasonication, repeat 2-4 times; vacuum-dry the obtained precipitate at 30-35...

Embodiment 1

[0079] This embodiment provides a method for preparing cuprous oxide nanospheres with a double-layer structure.

[0080] Step (1), 2.5g copper acetate is dissolved in 50ml water, obtains copper acetate aqueous solution; 0.25g sodium oleate is dissolved in 50ml ethanol, obtains the ethanol solution of sodium oleate;

[0081] In step (2), add the aqueous copper acetate solution and the ethanol solution of sodium oleate obtained in step (1) into a three-necked flask and stir for 5 minutes; dilute 1ml of hydrazine hydrate solution with a mass fraction of 80% to 10ml and add it dropwise to the reaction system middle;

[0082] Step (3), after the aqueous solution of hydrazine hydrate is added dropwise, the reaction is stirred and reacted at 20°C for 10 minutes, and the stirring speed is 600rpm;

[0083] Step (4), after the reaction, centrifuge the obtained reaction solution, remove the supernatant, add 10ml of ethanol and sonicate for 10 minutes, repeat 3 times; vacuum dry the obta...

Embodiment 2

[0090] This embodiment provides a method for preparing cuprous oxide nanospheres with a double-layer structure.

[0091] Step (1), 1.0g copper acetate is dissolved in 50ml water, obtains copper acetate aqueous solution; 0.25g sodium oleate is dissolved in 50ml ethanol, obtains the ethanolic solution of sodium oleate;

[0092] In step (2), add the aqueous copper acetate solution and the ethanol solution of sodium oleate obtained in step (1) into a three-necked flask and stir for 5 minutes; dilute 1ml of hydrazine hydrate solution with a mass fraction of 80% to 10ml and add it dropwise to the reaction system middle;

[0093] Step (3), after the aqueous solution of hydrazine hydrate is added dropwise, the reaction is stirred and reacted at 20°C for 10 minutes, and the stirring speed is 600rpm;

[0094] Step (4), after the reaction, centrifuge the obtained reaction solution, remove the supernatant, add 10ml of ethanol and sonicate for 10 minutes, repeat 3 times; vacuum dry the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap