Preparation method of lambada-MnO2

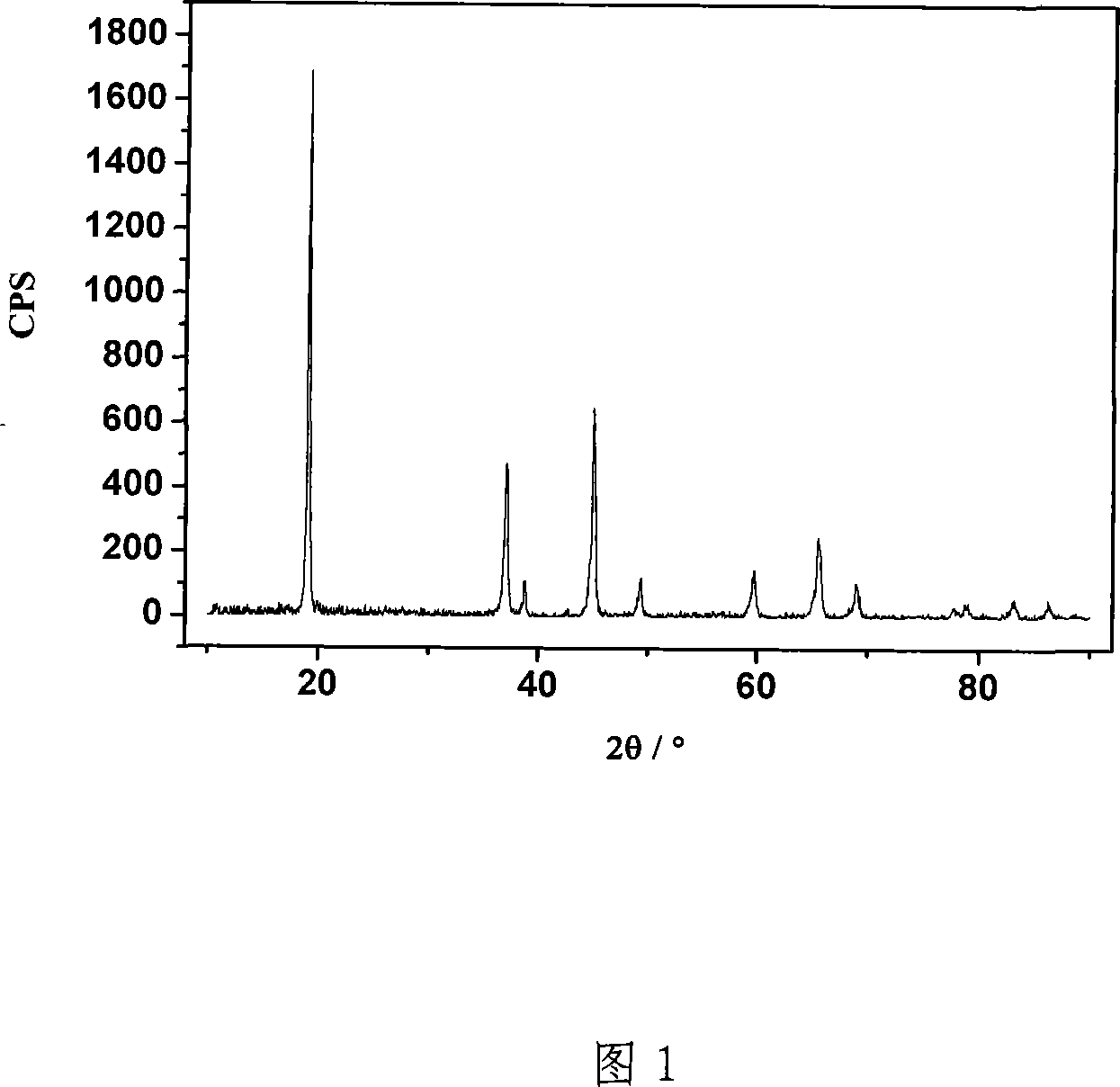

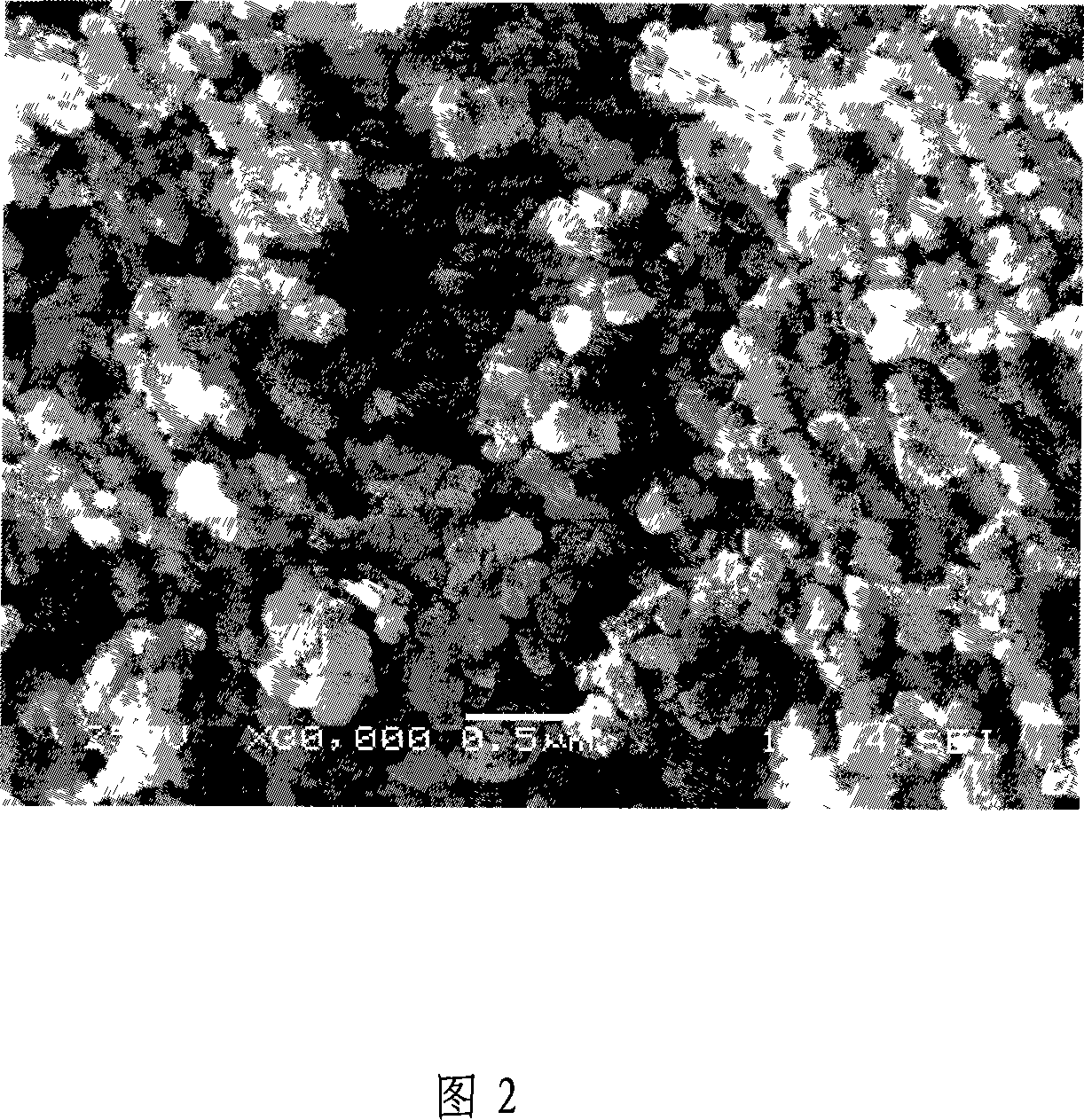

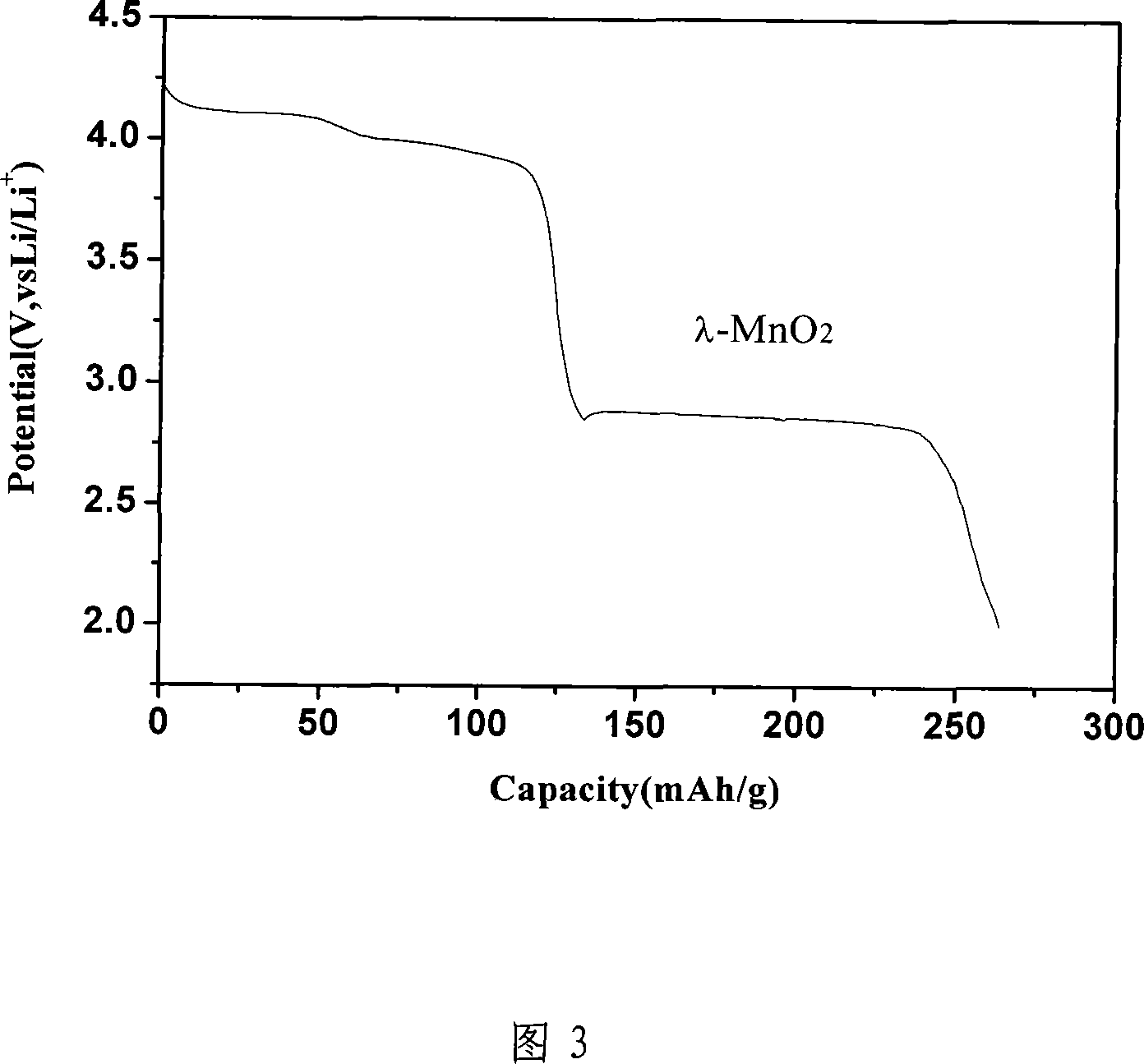

A technology of manganese oxide and lithium salt, which is applied in the field of MnO2 preparation, can solve the problems of high consumables, low product purity, time and energy consumption, etc., and achieve the effect of regular surface morphology, good discharge performance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh LiCO at a molar ratio of 1:4 3 and about 500g of EMD, and grind for 2h with a ball mill to mix the two materials evenly. Prepare the sample and put in Al 2 o 3 Put the crucible in a muffle furnace and smelt it at 600°C for 12 hours in an air atmosphere, cool it naturally, take out the sample, crush it, and mill it with a ball mill for 2 hours, then put it in a muffle furnace again and smelt it at 800°C in an air atmosphere for 24 hours , cooled naturally, the product was taken out, crushed and ball milled to 8-12 μm to obtain lithium manganese oxide.

[0023] Weigh 120g of lithium manganese oxide prepared by the above-mentioned method and disperse it in 200ml of deionized water, and keep the temperature of the mixture at 25°C in a water bath while continuously stirring vigorously. Take 140ml of 10M sulfuric acid and inject it dropwise into the mixture, keeping the temperature of the mixture at 25°C all the time until the pH value of the mixture is stabilized wi...

Embodiment 2

[0025] Weigh LiNO at a molar ratio of 1:2 3 and about 500g of EMD, add 100ml of ethanol as a dispersant, and mill in a ball mill for 2 hours to mix the two materials evenly. Prepare the sample and put in Al 2 o 3 The crucible is placed in a muffle furnace and smelted at 450°C for 16 hours in an air atmosphere, cooled, the sample is taken out, crushed and ball milled for 4 hours, placed in a muffle furnace again and smelted at 800°C for 20 hours in an air atmosphere, cooled, The product is taken out, pulverized and ball-milled to 8-12 μm to obtain lithium manganese oxide.

[0026] Weigh 120g of lithium manganese oxide prepared by the above-mentioned method and disperse it in 200ml of deionized water, and keep the temperature of the mixture at 20°C in a water bath while continuously stirring vigorously. Take 200ml of 15M concentrated nitric acid and inject it dropwise into the mixture, keeping the temperature of the mixture at 20°C until the pH value of the mixture is stabili...

Embodiment 3

[0028] Weigh about 500 g of LiOH and CMD at a molar ratio of 1:2, and mill them in a ball mill for 4 hours to mix the two materials evenly. Prepare the sample and put in Al 2 o 3The crucible is placed in a muffle furnace and smelted at 350°C for 10 hours in an air atmosphere, cooled, the sample is taken out, pulverized and ball milled for 2 hours, placed in a muffle furnace again and smelted at 750°C for 24 hours in an air atmosphere, cooled, The product is taken out, pulverized and ball-milled to 8-12 μm to obtain lithium manganese oxide.

[0029] Weigh 120g of lithium manganese oxide prepared by the above-mentioned method and disperse it in 200ml of deionized water, and keep the temperature of the mixture at 20°C in a water bath while continuously stirring vigorously. Take 200ml of 15M concentrated hydrochloric acid and inject it dropwise into the mixture, keeping the temperature of the mixture at 20°C until the pH value of the mixture is stabilized within 0.5-1. Continue...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap