Anti-skid cement mortar for tunnel pavement and preparation method thereof

A cement mortar and tunnel technology, which is applied in the field of anti-skid cement mortar for tunnel pavement and its preparation, can solve the problems of non-consideration of anti-skid performance, durability, impact resistance, poor wear resistance, insufficient toughness, etc., and achieve good durability , extended service life, high early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

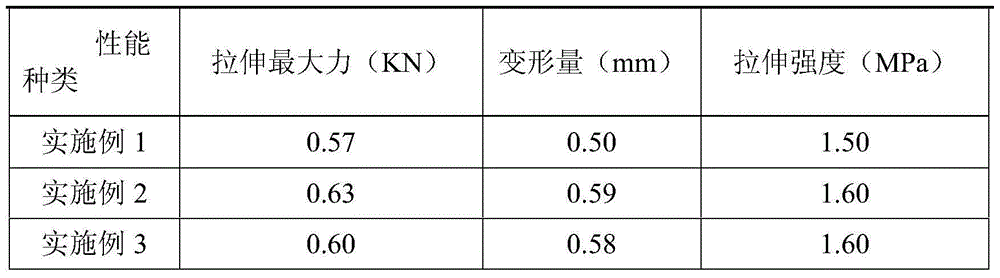

Embodiment 1

[0028] Pour 28.9 parts (parts by mass, the same below) of cement and 55 parts of quartz sand (fineness modulus 2.52) into a stirring tank for manual premixing; add 3 parts of water into the mixture of cement and sand and perform mechanical stirring for 60 seconds; mix 10 parts of Pour the styrene-acrylic emulsion (38% solid content) into the stirring tank, and rinse the container containing the styrene-acrylic emulsion twice with the remaining 3 parts of water, then pour it into the reaction kettle and stir for 120s; slowly add 0.05 parts respectively Naphthalene-based water reducer, 0.02 part of organosiloxane and 0.03 part of polyacrylamide are stirred evenly to obtain an anti-skid cement mortar.

[0029] According to the "Highway Engineering Cement and Cement Concrete Test Regulations" (JTGE30-2005) to test the setting time of the mortar, the initial setting time is 285min, and the final setting time is 515min. Considering the small thickness of the anti-skid layer and the ...

Embodiment 2

[0032] Pour 28 parts of cement and 54.88 parts of sand into the mixing tank for manual premixing; add 2.5 parts of water into the mixture of cement and sand for mechanical stirring for 60 seconds; pour 12 parts of polyvinyl acetate emulsion (40% solid content) into the mixing tank Reactor, and rinse the remaining 2.5 parts of water twice to the container holding the polymer, pour it into the reaction kettle and stir for 120s; slowly add 0.04 parts of polycarboxylate water reducer, 0.03 parts of organosiloxane With 0.02 part of polyvinyl alcohol and 0.03 part of polyacrylamide, stir evenly to obtain a kind of anti-skid cement mortar. Its initial setting time is 265min and final setting time is 500min; the 3d flexural strength is 4.6MPa, and the compressive strength is 27.8MPa.

Embodiment 3

[0034] Pour 28.5 parts of cement and 56.39 parts of quartz sand into the mixing tank for manual premixing; add 2 parts of water into the mixture of cement and sand and perform mechanical stirring for 90s; pour 11 parts of ethylene-vinyl acetate emulsion (solid content 40%) into the stirring tank, and rinse the remaining 2 parts of water twice to the container containing the polymer, then pour it into the reaction kettle and stir for 120s; slowly add 0.04 parts of polycarboxylate water reducer, 0.03 parts of silicon ether and 0.04 part of polyacrylamide, and stir evenly to obtain a kind of anti-skid cement mortar. Its initial setting time is 265min and final setting time is 505min; the 3d flexural strength is 4.9MPa, and the compressive strength is 28.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com