Aerogel composite material with multi-scale and multi-network composite structure and preparation method of aerogel composite material

A composite material and composite structure technology, applied in the field of inorganic composite materials, can solve problems such as limitation, lack of plasticity and formability, and achieve the effects of improving mechanical properties, suppressing powder drop phenomenon, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

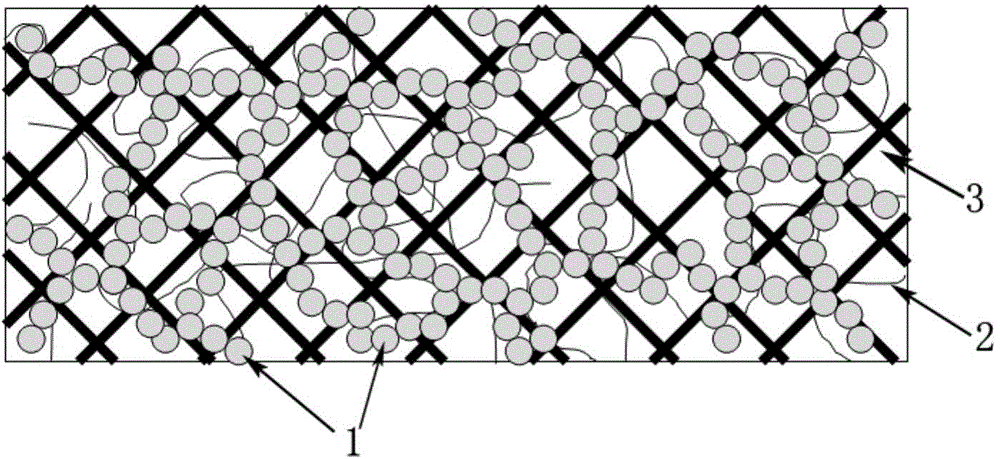

[0025] The preparation method of the airgel composite material with multi-scale multi-network composite structure proposed by the present invention comprises the following steps:

[0026] (1) adding cellulose to the aqueous solution of the airgel precursor with a molar concentration of 0.6 to 2.8mol / L, so that the mass ratio of cellulose to the airgel precursor is: cellulose: airgel precursor=1 : (0.06~0.5), obtain the first solution, described cellulose is plant cellulose powder, and described airgel precursor is any one in sodium silicate, potassium silicate or sodium metaaluminate ;

[0027] (2) Add cellulose crosslinking agent to the above-mentioned first solution, so that the mass ratio of cellulose and cellulose crosslinking agent is: cellulose: cellulose crosslinking agent=1: (0.6~1.5), stir under normal temperature Evenly, the second solution is obtained, and the cellulose crosslinking agent is any one of epichlorohydrin, formaldehyde or glutaraldehyde;

[0028] (3) ...

Embodiment 1

[0037] (1) adding cellulose to the aqueous solution of the airgel precursor with a molar concentration of 1.2mol / L, so that the mass ratio of cellulose to the airgel precursor is: cellulose: airgel precursor=1:0.3 , to obtain the first solution, the cellulose is plant cellulose powder, and the airgel precursor is sodium silicate;

[0038] (2) Add cellulose cross-linking agent in above-mentioned first solution, make the mass ratio of cellulose and cellulose cross-linking agent be: cellulose: cellulose cross-linking agent=1:0.8, stir under normal temperature, obtain the first Two solutions, the cellulose crosslinking agent is epichlorohydrin;

[0039] (3) The long glass fiber network is immersed in the second solution and left still, so that the mass ratio of cellulose and the long glass fiber network is: cellulose: long glass fiber network=1:0.7, and the standing time is 45 hours, so that the first The second solution is converted into a cellulose gel with a skeleton structure...

Embodiment 2

[0046] (1) adding cellulose to the aqueous solution of the airgel precursor with a molar concentration of 1.8mol / L, so that the mass ratio of cellulose to the airgel precursor is: cellulose: airgel precursor=1:0.15 , to obtain the first solution, the cellulose is plant cellulose powder, and the airgel precursor is potassium silicate;

[0047] (2) Add cellulose cross-linking agent in above-mentioned first solution, make the mass ratio of cellulose and cellulose cross-linking agent be: cellulose: cellulose cross-linking agent=1:1.2, stir under normal temperature, obtain the second Two solutions, the cellulose cross-linking agent is formaldehyde;

[0048] (3) The long glass fiber network is immersed in the second solution and left still, so that the mass ratio of cellulose and the long glass fiber network is: cellulose: long glass fiber network=1:1.2, and the standing time is 49 hours, so that the first The second solution is converted into a cellulose gel with a skeleton struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com