Method for concreting loose sand particles through biological phosphate/carbonate composite cementing material

A technology of composite cementitious materials and phosphate, which is applied in the field of foundation reinforcement, bio-phosphate and carbonate composite cementitious materials to consolidate loose sand particles, and can solve the problems of large capital investment, unfavorable large-scale application, environmental damage, etc. problems, to achieve the effect of small investment, avoid waste of resources, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

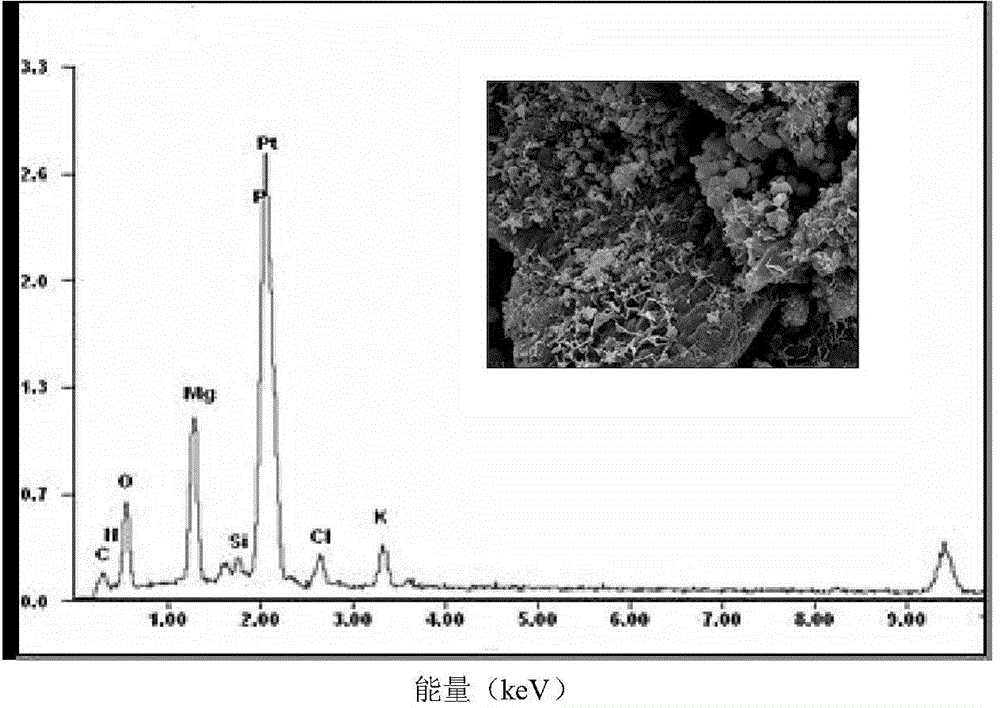

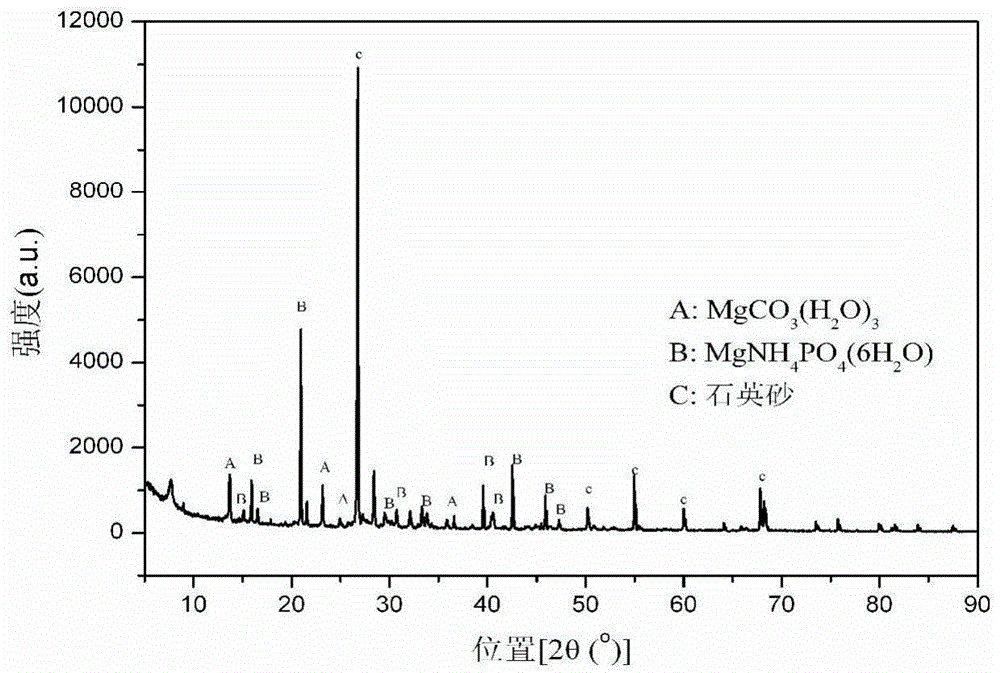

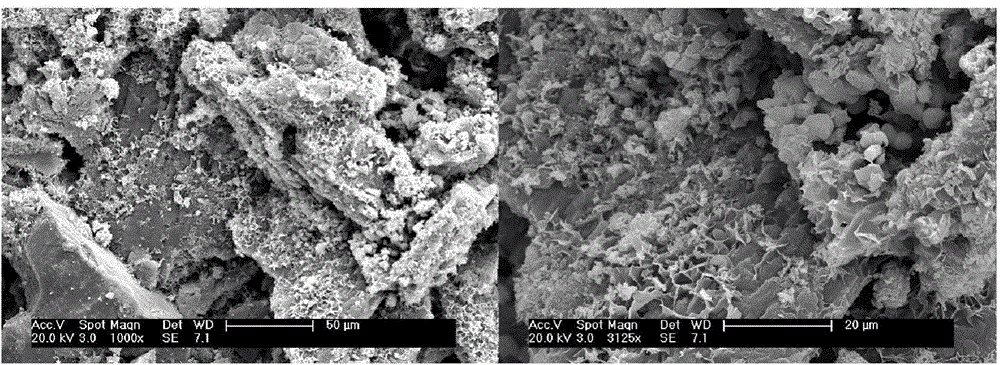

[0027] First, 1 mol K 2 HPO 4 The solid was completely dissolved in the pasteurized bacteria liquid (1 L) to obtain a phosphate bacteria liquid. Prepare 1L (1mol / l) urea and (2mol / l) magnesium chloride mixed solution. Pumping cemented high 6cm diameter 3cm quartz sand column (medium sand: 0.15-3.0, 90% fine sand: <0.15, 10%). First, 25ml of phosphate bacteria solution was pumped and injected into the sand column at 8ml / min, then 25ml of urea and magnesium chloride mixed solution was pumped and injected into the sand column at 6min / ml, and then 25ml of phosphate bacteria solution was injected into the sand column. After standing at 30°C for 1.5h, inject 25ml of mixed solution of urea and magnesium chloride into the sand column; then inject 25ml of phosphate bacteria solution into the sand column, after standing at 30°C for 1.5h, and so on, until it cannot be injected until the sand column. The belt mold was placed in an oven at 45°C for 14 days, and after the mold was remov...

Embodiment 2

[0029] First, 1 mol K 2 HPO 4 The solid was completely dissolved in the pasteurized bacteria liquid (1 L) to obtain a phosphate bacteria liquid. Prepare 1L (1mol / l) urea and (2mol / l) magnesium chloride mixed solution. Pumping cemented high 6cm diameter 3cm quartz sand column (medium sand: 0.15-3.0, 90% fine sand: <0.15, 10%). First, 25ml of phosphate bacteria solution was pumped and injected into the sand column at 10ml / min, and then 25ml of urea and magnesium chloride mixed solution was pumped and injected into the sand column at 8min / ml, and then 25ml of phosphate bacteria solution was injected into the sand column. After standing at 30°C for 2 hours, inject 25ml of mixed solution of urea and magnesium chloride into the sand column; then inject 25ml of phosphate bacteria solution into the sand column, after standing at 30°C for 2 hours, and so on, until the sand column cannot be injected until. The belt mold was placed in an oven at 45°C for 14 days, and after the mold w...

Embodiment 3

[0031] Configuration 1 first converts 1 mol K 2 HPO 4The solid was completely dissolved in the pasteurized bacteria liquid (1 L) to obtain a phosphate bacteria liquid. Prepare 1L (1mol / l) urea and (2mol / l) magnesium chloride mixed solution. Pumping cemented high 6cm diameter 3cm quartz sand column (medium sand: 0.15-3.0, 90% fine sand: <0.15, 10%). First, 25ml of phosphate bacteria solution was pumped and injected into the sand column at 16ml / min, then 25ml of urea and magnesium chloride mixed solution was pumped and injected into the sand column for 10min / ml, and then 25ml of phosphate bacteria solution was injected into the sand column. After standing at 30°C for 2 hours, inject 25ml of mixed solution of urea and magnesium chloride into the sand column; then inject 25ml of phosphate bacteria solution into the sand column, after standing at 30°C for 2 hours, and so on, until the sand column cannot be injected until. The belt mold was placed in an oven at 45°C for 10 days,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com