Nanometer composite non-asbestos heat insulation felt and production method thereof

A nano-composite, production method technology, applied in the field of nano-composite non-asbestos thermal insulation felt, can solve the problems of large environmental impact, unwillingness of on-site construction personnel, difficulty in selecting thermal insulation materials, etc., and achieve low thermal conductivity at room temperature and excellent thermal insulation performance , the effect of small bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put 22 kg of brucite fiber (a fourth-grade product produced by Shaanxi Nanfang Metal Mining Co., Ltd.) in the raw material processor, add an appropriate amount of industrial pure water (chloride ion content is less than 5 mg / kg, conductivity (25 °C) is less than 10 μS / cm industrial pure water), soak for 20-30 minutes, then clear with industrial pure water, drain the cleaning water, and repeat this until the chloride ion content in the cleaning water is less than 95 mg / kg.

[0039] Add 10 kg of aluminum silicate fiber cotton, 3.8 kg of debonding agent (dioctyl sodium sulfosuccinate) and 540 kg of industrial pure water into the stirring tank; after 5 minutes after starting up, add the brucite fiber treated by the above steps 22 kilograms, and 1.8 kilograms of modified dispersants, 4 kilograms of inorganic active soil, 16 kilograms of sepiolite wool and 0.9 kilograms of loosening agent (sodium hexametaphosphate) are added to the stirring tank; after continuing to stir for ...

Embodiment 2~10

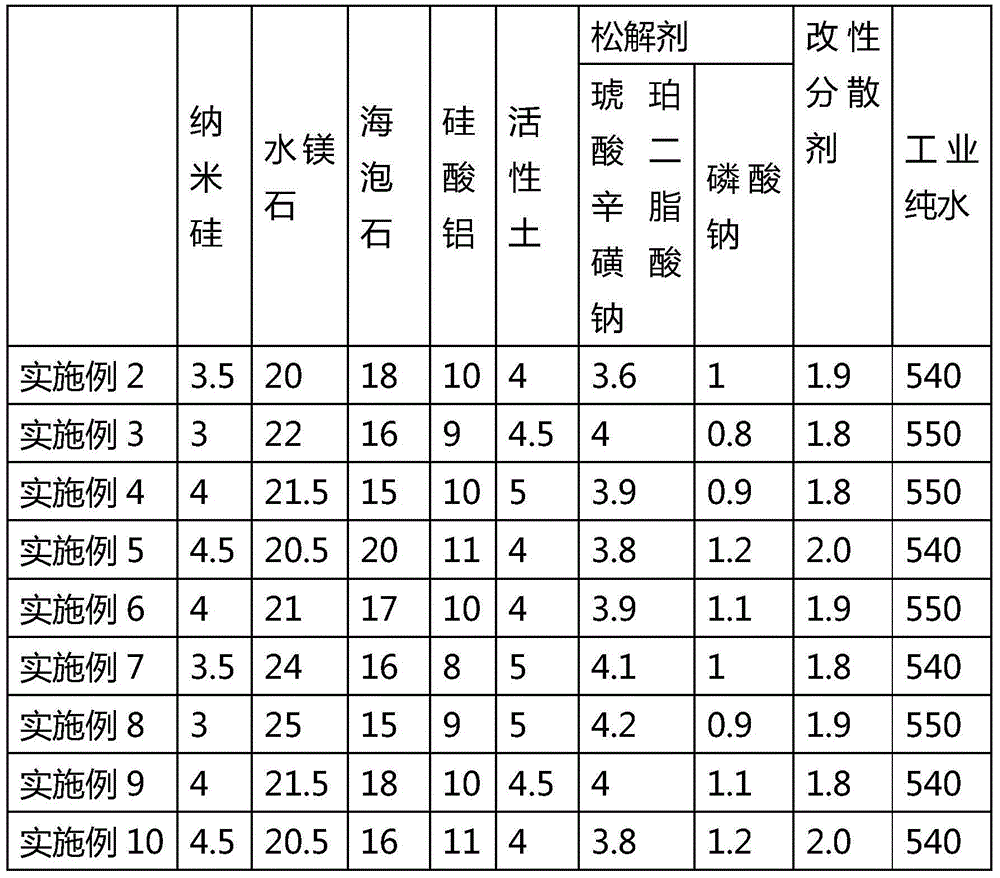

[0046] Using the raw materials and dosages listed in Table 2 below, the same treatment as in Example 1 (wherein the brucite fiber treatment method is the same as that of the brucite fiber in Example 1) was used to obtain products 2-10. The complexing dose used in each embodiment is 0.2 kg.

[0047] Table 2: The raw material quantity (unit: kilogram) that uses among the embodiment 2~10

[0048]

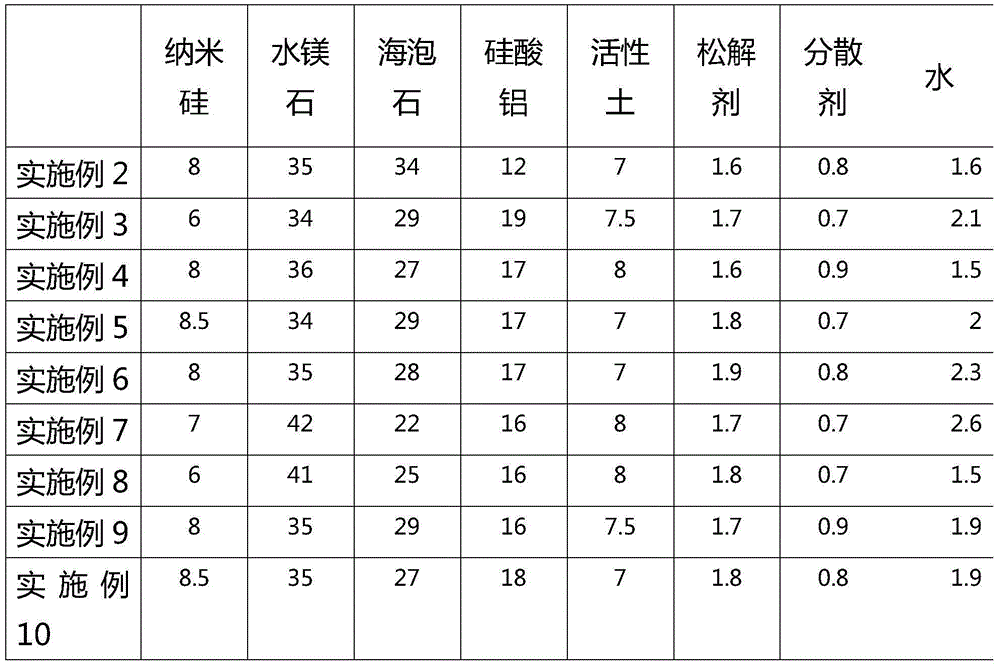

[0049] The contents and performance indexes of each component in products 2-10 are shown in Table 3 and Table 4 below.

[0050] Table 3: each component content (weight %) table in the finished product of embodiment 2~10

[0051]

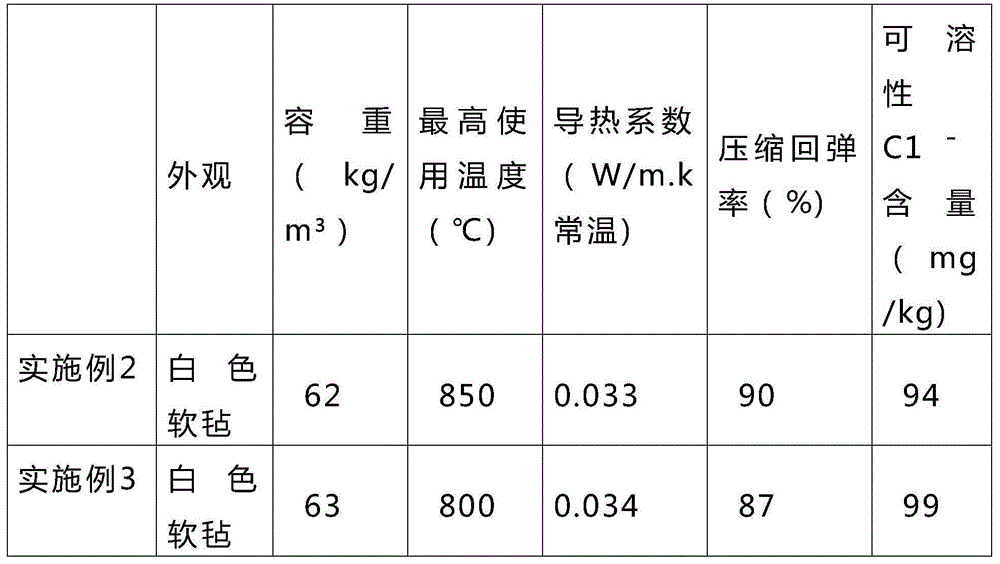

[0052] Table 4: Performance Index Table of Products 2-10 of Examples 2-10

[0053]

[0054]

[0055] The thermal insulation performance of the product of the present invention is far superior to that of common thermal insulation blankets, and its main performances are compared with those of common thermal insulation blankets, as shown in Table 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com