Environment-friendly energy-saving bio-organic fertilizer fermentation equipment

A bio-organic fertilizer and fermentation equipment technology, applied in the direction of organic fertilizer equipment, organic fertilizer preparation, organic fertilizer, etc., can solve the problems of not meeting the requirements, backward production technology, low production efficiency, etc., to prevent excessive temperature or Too low, increase the air input temperature, and ensure the effect of survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

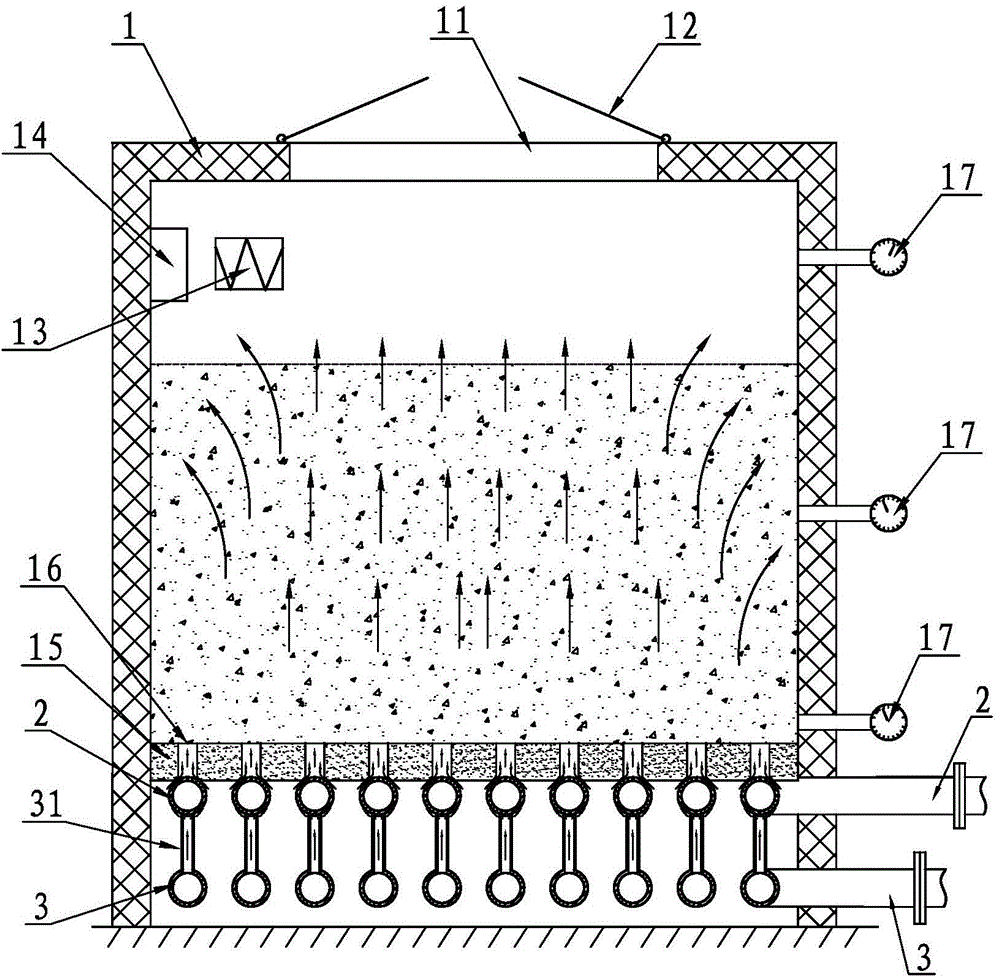

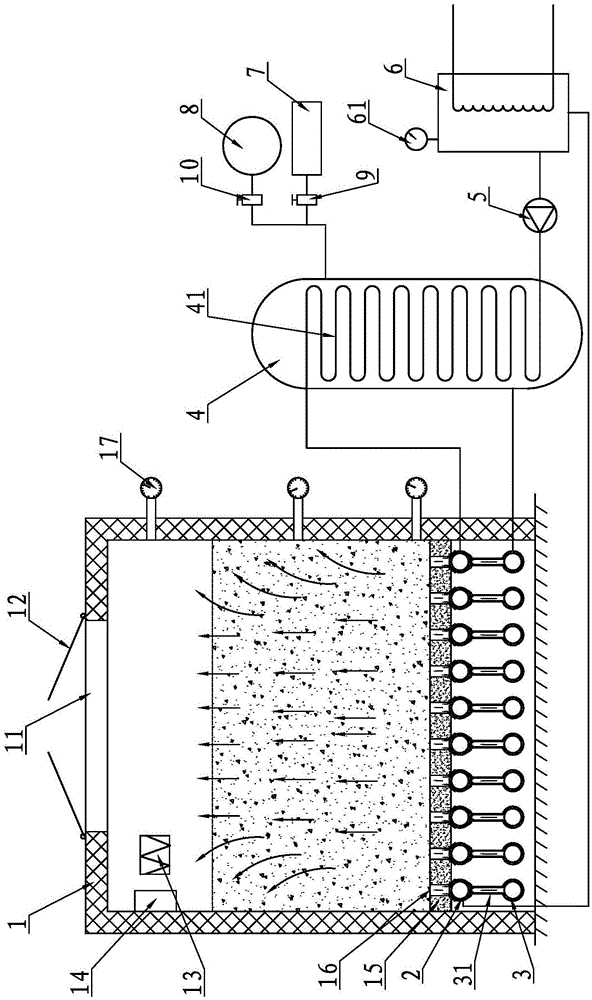

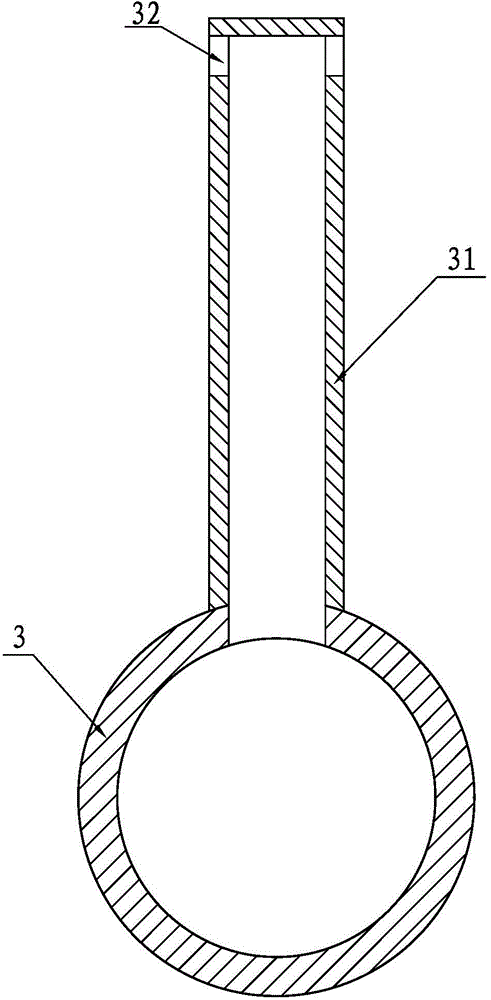

[0022] A kind of environment-friendly and energy-saving bio-organic fertilizer fermentation equipment, such as Figure 1 ~ Figure 3 As shown, it includes a thermal insulation charging box 1, a thermal oil pipe group 2, a hot gas pipe group 3, a heating gas tank 4, an oil delivery pump 5, a heating oil tank 6, an air compressor 7 and an oxygen supply blower 8. In the thermal insulation charging box 1 is provided with a feeding port 11, a self-closing pressure door 12 is provided at the feeding port 11, a heater 13 and a waterproof internal circulation fan 14 are provided on the top side of the thermal insulation charging box 1, and the air outlet of the waterproof internal circulation fan 14 Live heater 13; hot oil pipe group 2 and hot gas pipe group 3 are all arranged under the concrete bearing bottom layer 15 at the bottom of insulation charging box 1, and hot gas pipe group 3 is arranged below the hot oil pipe group 2, and the hot gas pipe group Each trachea body of 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com