Di-p-toluoyl-D-tartaric acid synthetic method

A technology of methyl dibenzoyl tartaric acid and methyl dibenzoyl tartaric acid anhydride, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of carboxylic acid halides, etc., can solve the problem of low utilization rate of raw materials and inability to recover Utilization, low process yield and other problems, to achieve the effects of convenient control, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of synthetic method of D-p-methyl dibenzoyl tartaric acid, it comprises the steps:

[0036] Take 150g of D-tartaric acid and 200ml of toluene in a 1000ml three-neck bottle, add 1.5g of copper sulfate under stirring, start to add 330g of p-toluoyl chloride dropwise, finish dropping in 3 hours, continue to react for 6 hours, discharge the material into a centrifuge, and shake Filter to get 495.4g of D-p-methyldibenzoyl tartaric anhydride, put it into a 2000ml three-necked bottle, add 495.4g of water and toluene, heat up to reflux, keep it for 5 hours, cool down to normal temperature and discharge, shake off to get D-p Methyl dibenzoyl tartaric acid 374.4g.

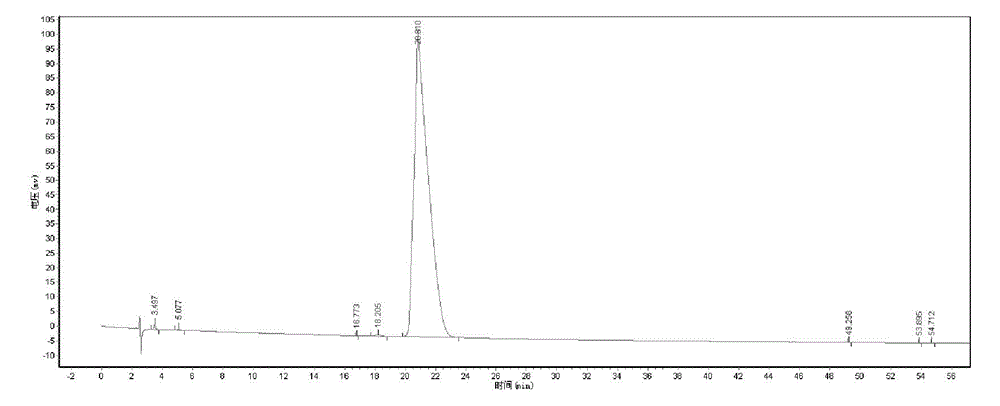

[0037] The D-p-methyldibenzoyl tartaric acid that present embodiment obtains is carried out TEM test, test structure such as figure 1 Shown, as can be seen from the figure, the finished product D-p-methyldibenzoyl tartaric acid purity content is 99.61%, and the total yield is 96.6%.

[0038] Peak number Peak ...

Embodiment 2

[0049] A kind of synthetic method of D-p-methyl dibenzoyl tartaric acid, it comprises the steps:

[0050]Put 1.5kg of D-tartaric acid and 2L of toluene into a 10L three-necked bottle, add 20g of copper sulfate under stirring, start to add 3.5kg of p-toluoyl chloride dropwise, finish dropping in 3 hours, continue to react for 6 hours, and discharge to the centrifuge. Get 4.88kg of D-p-methyldibenzoyl tartaric anhydride by rejection filtration, put it into a 20L three-necked bottle, add 4.88kg of water and toluene each, heat up to reflux, keep for 5 hours, cool to normal temperature and discharge, and shake to obtain D- 3.71kg of p-methyldibenzoyl tartaric acid.

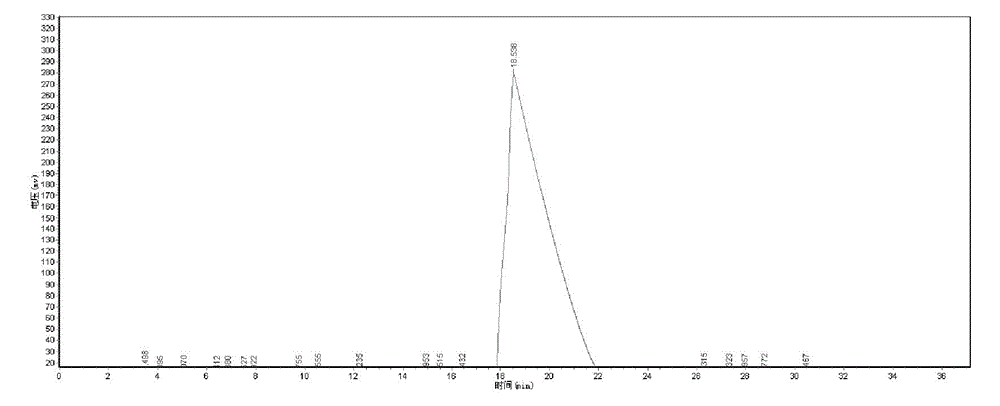

[0051] The D-p-methyldibenzoyl tartaric acid that present embodiment obtains is carried out TEM test, test structure such as figure 2 As shown, as can be seen from the figure, the purity content of finished product D-p-methyldibenzoyl tartaric acid is 99.76%, and the total yield is 95.9%.

[0052] Peak number Peak n...

Embodiment 3

[0073] A kind of synthetic method of D-p-methyl dibenzoyl tartaric acid, it comprises the steps:

[0074] Put 7.5kg of D-tartaric acid and 10L of toluene into a 50L reaction kettle, add 120g of copper sulfate under stirring, start to add 18kg of p-toluyl chloride dropwise, finish dropping in 4 hours, continue to react for 6 hours, discharge the material into a centrifuge, and shake Filter to get 24.9kg of D-p-methyldibenzoyl tartaric anhydride, put it into a 100L reactor, add 24.9kg of water and toluene, heat up to reflux, keep for 5 hours, cool to normal temperature and discharge, shake off to get D-p Methyl dibenzoyl tartaric acid 18.5kg.

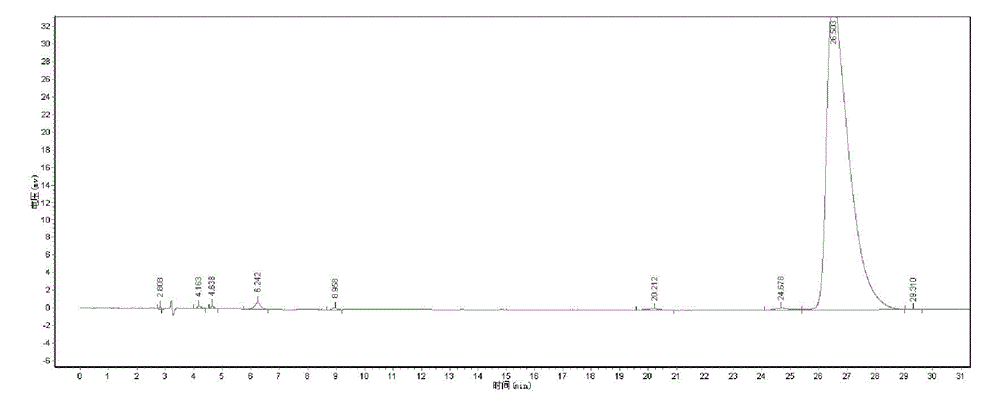

[0075] The D-p-methyldibenzoyl tartaric acid that present embodiment obtains is carried out TEM test, test structure such as image 3 Shown, as can be seen from the figure, the finished product D-p-methyldibenzoyl tartaric acid purity content is 99.34%, and the total yield is 95.2%.

[0076] Peak number Peak name Retention time Peak hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com