DOP (dioctylphthalate) esterification reaction system and production process

An esterification reaction and esterification technology, applied in the field of DOP production, can solve the problems of high production cost, no improvement, complicated process, etc., and achieve the effect of saving dosage, shortening working time, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

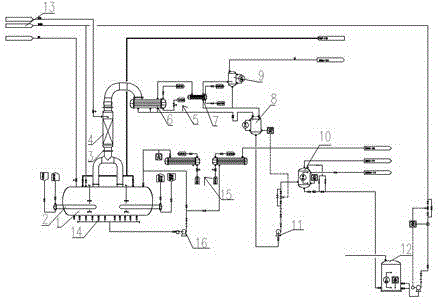

[0026] Such as figure 1 As shown, the DOP esterification reaction system includes a reactor 1 capable of storing the mixed solution, and the two ends of the reactor are provided with an input pipeline 2, and the mixed solution includes phthalic anhydride, octanol and a catalyst; the reactor is connected with a gas riser 3, and the gas riser and The esterification tower 4 communicates, and the upper end of the esterification tower is connected with the first cooling group 5, and the first cooling group includes two series-connected first treatment coolers 6 and the second treatment cooler 7, and are all connected with the first collector The tank 8 is connected, and a second collection tank 9 is connected to one side of the second processing cooler, and the bottom of the second collection tank communicates with the first collection tank. One side of the first cooling group is connected with the alcohol-water separation tank 10 through the first collection tank, and a condensate...

Embodiment 2

[0036] Such as figure 1 As shown, the DOP esterification reaction system includes a reactor 1 capable of storing the mixed solution, and the two ends of the reactor are provided with an input pipeline 2, and the mixed solution includes phthalic anhydride, octanol and a catalyst; the reactor is connected with a gas riser 3, and the gas riser and The esterification tower 4 communicates, and the upper end of the esterification tower is connected with the first cooling group 5, and the first cooling group includes two series-connected first treatment coolers 6 and the second treatment cooler 7, and are all connected with the first collector The tank 8 is connected, and a second collection tank 9 is connected to one side of the second processing cooler, and the bottom of the second collection tank communicates with the first collection tank. One side of the first cooling group is connected with the alcohol-water separation tank 10 through the first collection tank, and a condensate...

Embodiment 3

[0046] Such as figure 1 As shown, the DOP esterification reaction system includes a reactor 1 capable of storing the mixed solution, and the two ends of the reactor are provided with an input pipeline 2, and the mixed solution includes phthalic anhydride, octanol and a catalyst; the reactor is connected with a gas riser 3, and the gas riser and The esterification tower 4 communicates, and the upper end of the esterification tower is connected with the first cooling group 5, and the first cooling group includes two series-connected first treatment coolers 6 and the second treatment cooler 7, and are all connected with the first collector The tank 8 is connected, and a second collection tank 9 is connected to one side of the second processing cooler, and the bottom of the second collection tank communicates with the first collection tank. One side of the first cooling group is connected with the alcohol-water separation tank 10 through the first collection tank, and a condensate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com