Extraction process of purple sweet potato anthocyanin pigment

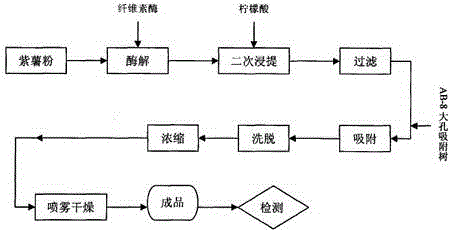

A purple sweet potato anthocyanin and pigment technology, which is applied in azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problem of low extraction rate of purple sweet potato anthocyanin pigment, low quality of purple sweet potato anthocyanin pigment, and poor quality of purple sweet potato anthocyanin pigment. It is easy to cause problems such as pollution of purification equipment, so as to achieve the effect of optimizing the extraction and purification process, high quality and reduced impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment Embodiment 1

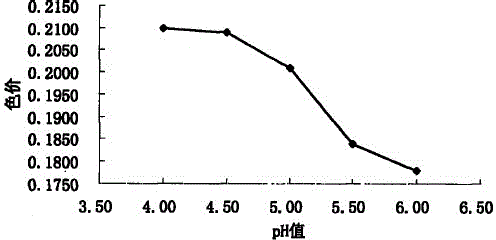

[0036] Experimental example 1: the pH value of anthocyanin pigment solution is set to 4.0, 4.5, 5.0, 5.5, 6.0 respectively, other conditions are temperature 25 ℃, enzyme amount 1.5%, substrate concentration 1: 5, enzymolysis time 30min, detect the absorbance of anthocyanin pigment solution after enzymatic hydrolysis, and calculate the color value of anthocyanin pigment solution, draw figure 2 The curve shown. Depend on figure 2 It can be seen that acidic conditions are conducive to the enzymatic hydrolysis of purple sweet potato cell membrane by cellulase, thereby releasing more anthocyanin pigments.

experiment Embodiment 2

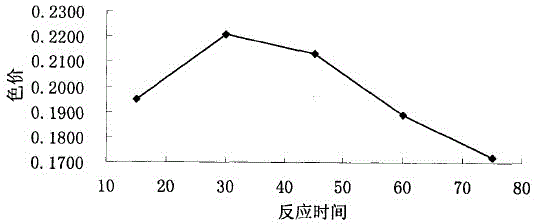

[0037] Experimental Example 2: Set the enzymolysis extraction reaction time to 15min, 30min, 45min, 60min, 75min respectively, other conditions are temperature 25°C, enzyme addition 1.5%, substrate concentration 1:5, pH value 4.0, enzymolysis Detect the absorbance of anthocyanin pigment solution after finishing, and calculate the color value of anthocyanin pigment solution, draw image 3 The curve shown.

[0038] Depend on image 3 It can be seen that the color value decreases after 30 minutes of reaction. This is because the cellulase acts for a long time and destroys the anthocyanin pigment, so the most suitable reaction time for enzymatic hydrolysis is determined to be 30 minutes.

experiment Embodiment 3

[0039] Experimental example 3: the enzymolysis extraction reaction temperature is respectively set to 25 ℃, 30 ℃, 35 ℃, 40 ℃, 45 ℃, other conditions are reaction time 30min, enzyme amount 1.5%, substrate concentration 1: 5, pH Value 4.0, detect the absorbance of anthocyanin pigment solution after enzymolysis, and calculate the color value of anthocyanin pigment solution, draw Figure 4 The curve shown. Depend on Figure 4 It can be seen that the color value is the lowest when the temperature is 30°C, indicating that the cellulose destroys anthocyanin pigments at this temperature. After that, the extraction rate increases with the increase of temperature, but the increase is slow after 40°C. In order to ensure a high extraction rate and make the present invention more energy-saving, 40° C. is the optimum temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com