Method for increasing quantum yield of up-conversion nano material

A technology of quantum yield and nanomaterials, applied in the field of preparation of upconversion nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Weigh 0.195g YCl 3 (1mmol) solid was added to a 100mL three-necked flask, followed by 6mL oleic acid (OA) and 15mL 1-octadecene (ODE), magnetically stirred under vacuum and gradually heated to 100°C, kept for 10min, and removed from the solvent O 2 and water. The temperature was then raised to 150 °C and maintained for 30 min to form a homogeneous transparent yellow solution. After naturally cooling to room temperature, stop vacuuming, and add 10 mL of dissolved 0.1482 g (4 mmol) NH 4 CH of F and 0.1 g (2.5 mmol) NaOH 3 OH solution, heated to 100°C in air and maintained for 10min to remove methanol in the solvent. Then vacuum at this temperature for 10 min to remove O in the system 2 and water. after N 2 Under the protective atmosphere, the temperature was raised rapidly to 290° C., and the reaction was maintained at this temperature for 240 minutes. After the system was naturally cooled to room temperature, stop passing N 2 . The resulting sample was wash...

Embodiment 2

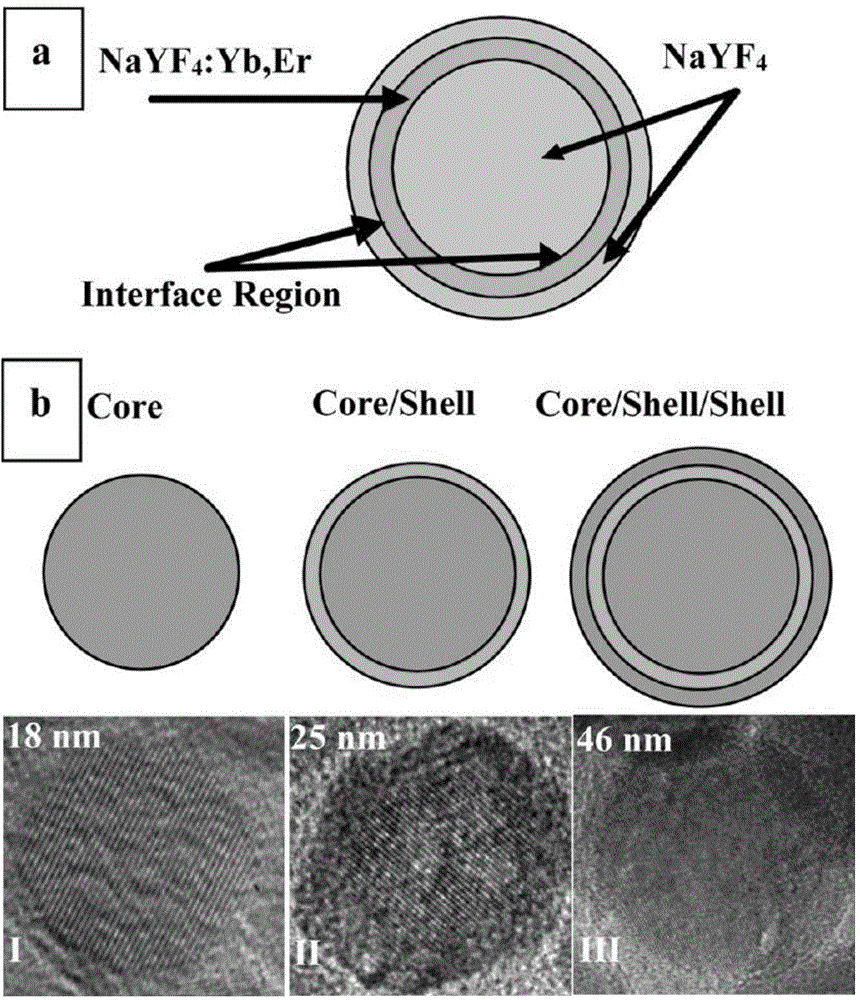

[0044] (1) Nuclear NaYF 4 The preparation is the same as in Example 1, except that the reaction temperature is 300°C, and the reaction is kept at this temperature for 120 minutes to obtain NaYF 4 , the shape is polyhedron, the particle size is about 20nm, and the yield is about 27%.

[0045] (2) Core-shell structure NaYF 4 NaYF 4 : Yb, the preparation of Er is the same as in Example 1, the difference is that the reaction temperature is 300°C, and the reaction is kept at this temperature for 60min to obtain NaYF 4 NaYF 4 : Yb, Er, polyhedral morphology, particle size about 22nm, yield about 8%.

[0046] (3) δ-doped NaYF 4 : Yb, the preparation of Er is the same as in Example 1, the difference is that the reaction temperature is 300°C, and the reaction is kept at this temperature for 60min to obtain NaYF 4 NaYF 4 :Yb,ErNaYF 4 , the shape is polyhedron, the particle size is about 25nm, and the yield is <5%.

Embodiment 3

[0048] (1) Nuclear NaYF 4 The preparation is the same as in Example 1, except that the reaction temperature is 310°C, and the reaction is kept at this temperature for 60 minutes to obtain NaYF 4 , the morphology is hexagonal sheet, the particle size is about 20nm, and the yield is about 32%.

[0049] (2) Core-shell structure NaYF 4 NaYF 4 : Yb, the preparation of Er is the same as in Example 1, except that the reaction temperature is 310°C, and the reaction is kept at this temperature for 30min to obtain NaYF 4 NaYF 4 : Yb, Er, the shape is hexagonal plate, the particle size is about 22nm, and the yield is about 24%.

[0050] (3) δ-doped NaYF 4 : Yb, the preparation of Er is the same as in Example 1, except that the reaction temperature is 310°C, and the reaction is kept at this temperature for 30min to obtain NaYF 4 NaYF 4 :Yb,ErNaYF 4 , the morphology is hexagonal sheet, the particle size is about 25nm, and the yield is about 17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com