Measuring method for crystallinity and crystalline state structure of tobacco cellulose

A technology of tobacco cellulose and determination method, which is applied in the field of determination of crystallinity and crystalline structure, and can solve the problems of poor measurement accuracy, unreported structure and crystallinity analysis, and large differences in chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

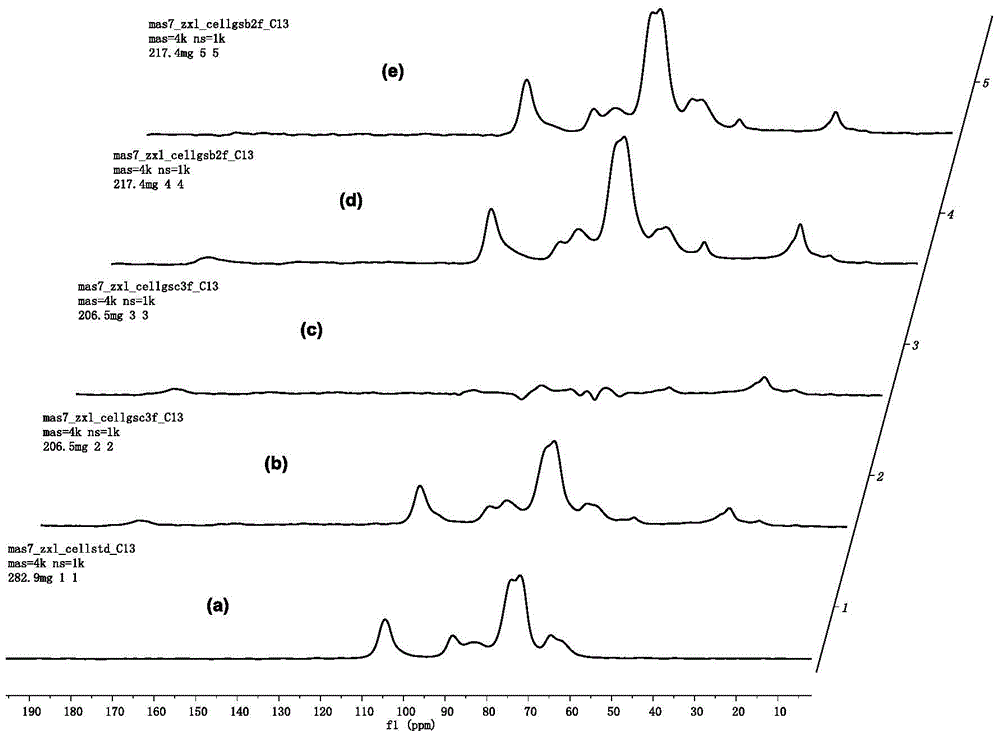

[0084] Selection of flue-cured tobacco samples from Guizhou C 3 F is processed according to the aforementioned step A to obtain a reference standard sample of flue-cured tobacco cellulose, and the cellulose content of the reference standard sample of flue-cured tobacco cellulose is 9.84%. Obtain the non-cellulose absorption background spectrum of the flue-cured tobacco sample according to the aforementioned step B. Then select the flue-cured tobacco sample to be tested for detection according to the aforementioned steps C to D, and compare the results with the previous XRD method and IR method. The crystallinity of the flue-cured tobacco sample to be tested is shown in Table 1.

[0085] Table 1: Crystallinity of cellulose in different flue-cured tobacco samples

[0086]

[0087]

[0088] Note: * is obtained from the formula for calculating the area of crystal region and amorphous region by NMR method;

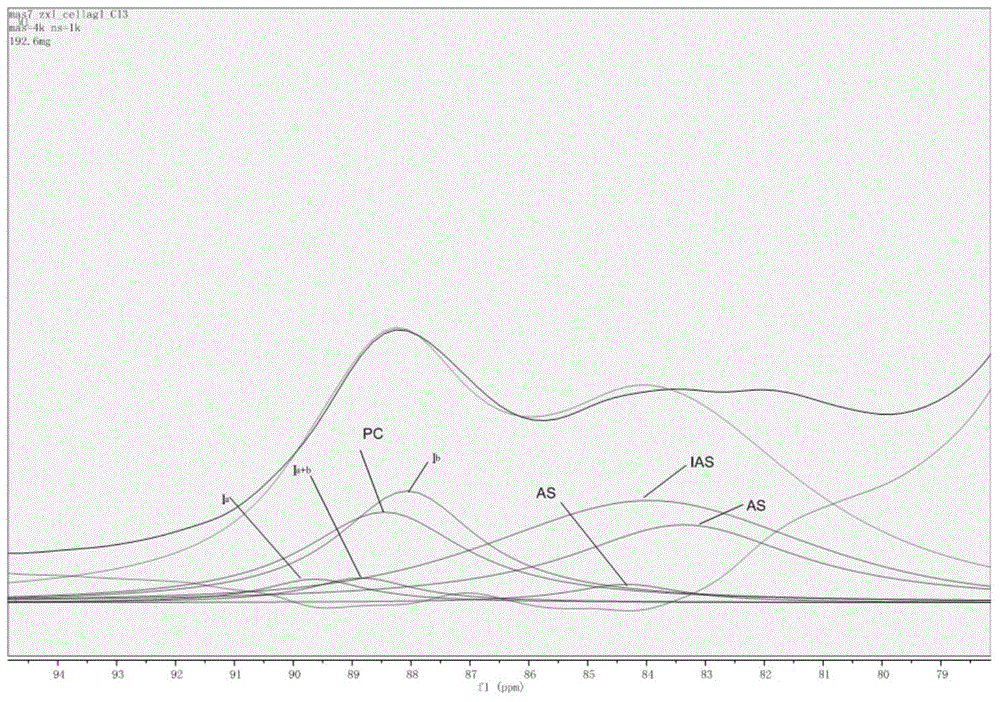

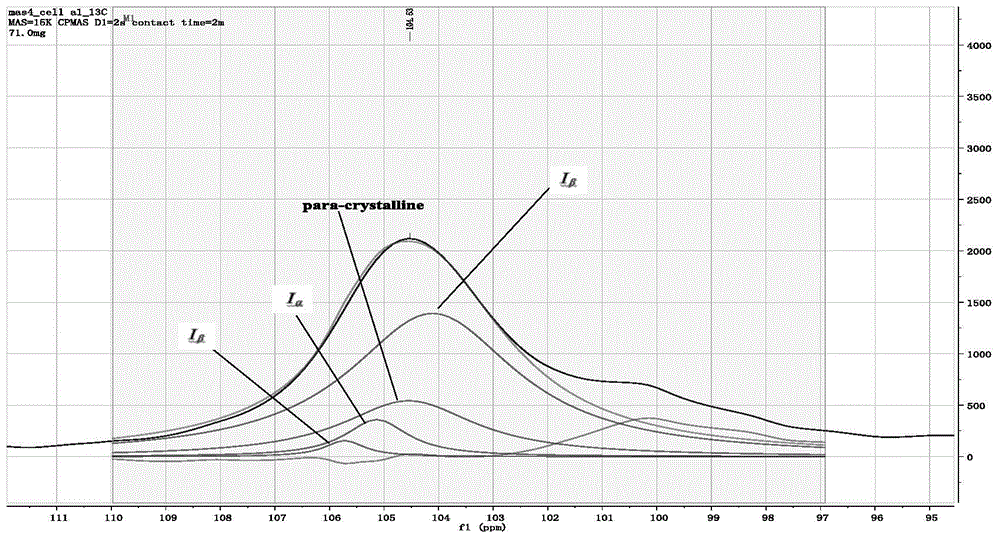

[0089] **for 13 C NMR spectrum fitted by cellulose crystal form...

Embodiment 2

[0098] The Hunan oriental tobacco sample was selected and processed according to the aforementioned step A to obtain a reference standard sample of oriental tobacco cellulose, and the cellulose content of the reference standard sample of oriental tobacco cellulose was 11.12%. Obtain the non-cellulose absorption background spectrum of the oriental tobacco sample according to the aforementioned step B. Then, the Hunan oriental tobacco samples were tested according to the aforementioned steps C to D, and compared with the detection results of the previous XRD method and IR method. The crystallinity of the oriental tobacco samples to be tested is shown in Table 4.

[0099] Table 4: Crystallinity of Oriented Tobacco Sample Cellulose

[0100]

[0101] Note: * is obtained from the formula for calculating the area of crystallized region and amorphous region by NMR method;

[0102] **for 13 C NMR spectrum fitted by cellulose crystal form I α , I α+β and I β and the sum of the...

Embodiment 3

[0111] The Hubei burley tobacco sample was selected and processed according to the aforementioned step A to obtain a burley tobacco cellulose reference standard sample, and the cellulose content of the burley tobacco cellulose reference standard sample was 14.95%. The non-cellulose absorption background spectrum of the Burley tobacco sample was obtained according to the previous step B. Then the Hunan Burley tobacco samples were tested according to the aforementioned steps C to D, and compared with the previous XRD and IR method detection results, the crystallinity of the Burley tobacco samples to be tested is shown in Table 7.

[0112] Table 7: Crystallinity of Burley tobacco sample cellulose

[0113]

[0114]

[0115] Note: * is obtained from the formula for calculating the area of crystallized region and amorphous region by NMR method;

[0116] **for 13 C NMR spectrum fitted by cellulose crystal form I α , I α+β and I β and the sum of the relative content of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com