High-molecular gas sensitive material as well as preparation method and application thereof

A technology of gas-sensitive materials and polymers, which is applied in the field of polymer gas-sensitive materials and their preparation, can solve the problems of inability to have both responsivity and good recovery, achieve recovery rate and reuse rate, and increase the scope of application , the effect of large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

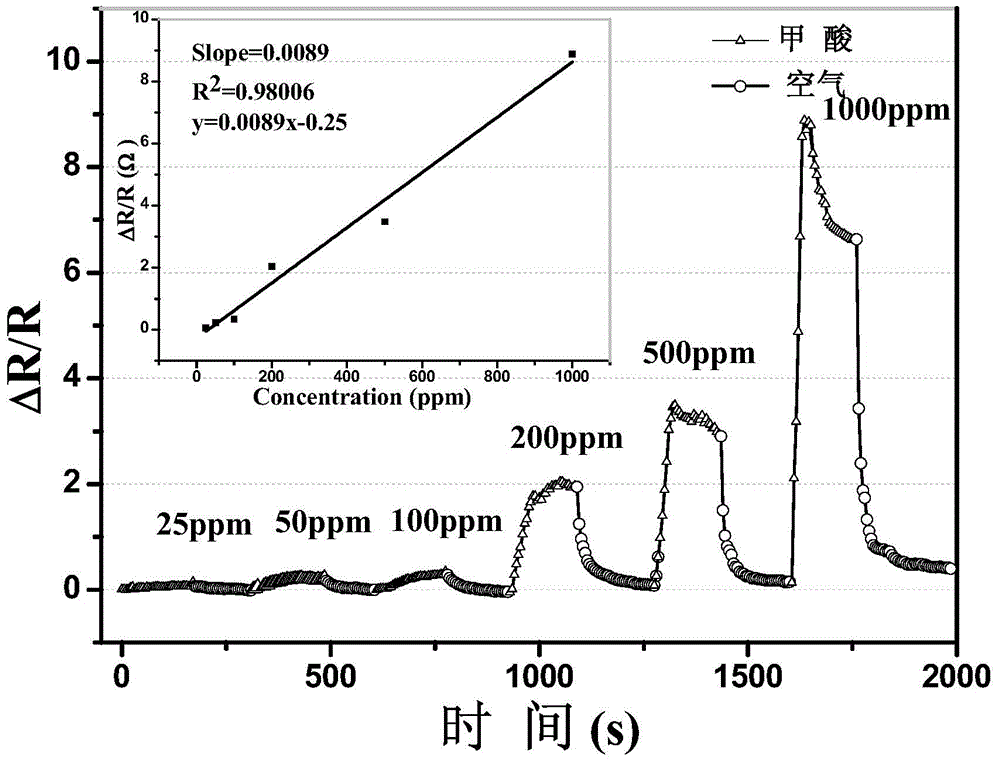

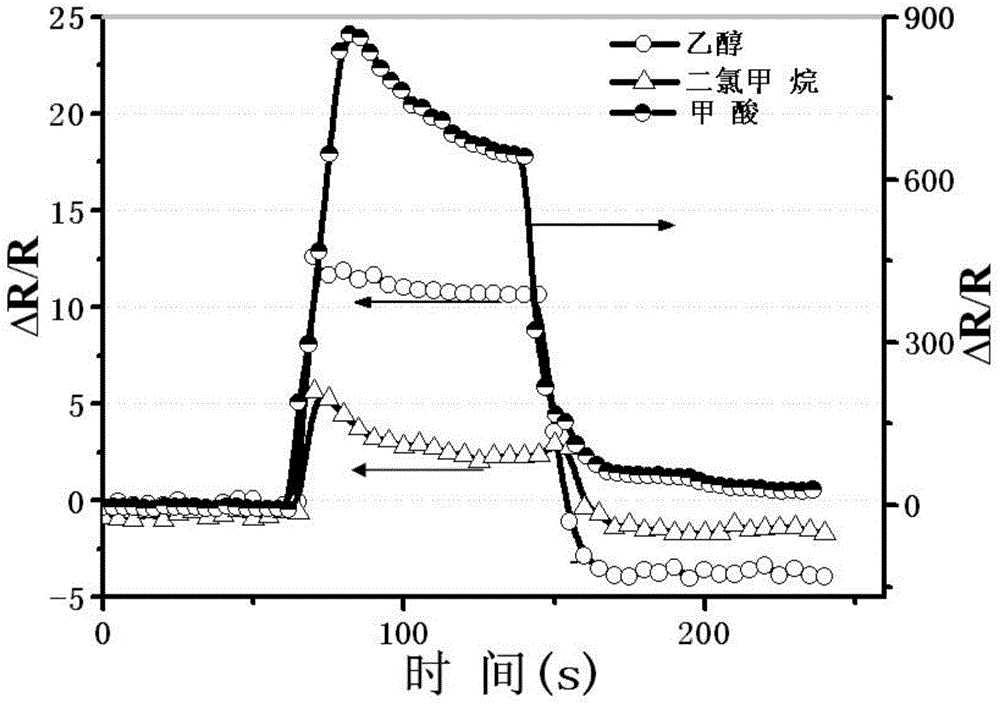

Examples

Embodiment 1

[0041] The preparation of embodiment 1 polymer gas-sensitive material

[0042] Preparation method: the specific preparation steps are as follows:

[0043] (1) Configuration of PA6 formic acid solution: Mix 1.5g of nylon 6 and 5ml of formic acid in a 50ml round bottom flask, then mechanically blend at 75°C for 1.5 hours to prepare a nylon 6 solution with a mass fraction of 20%.

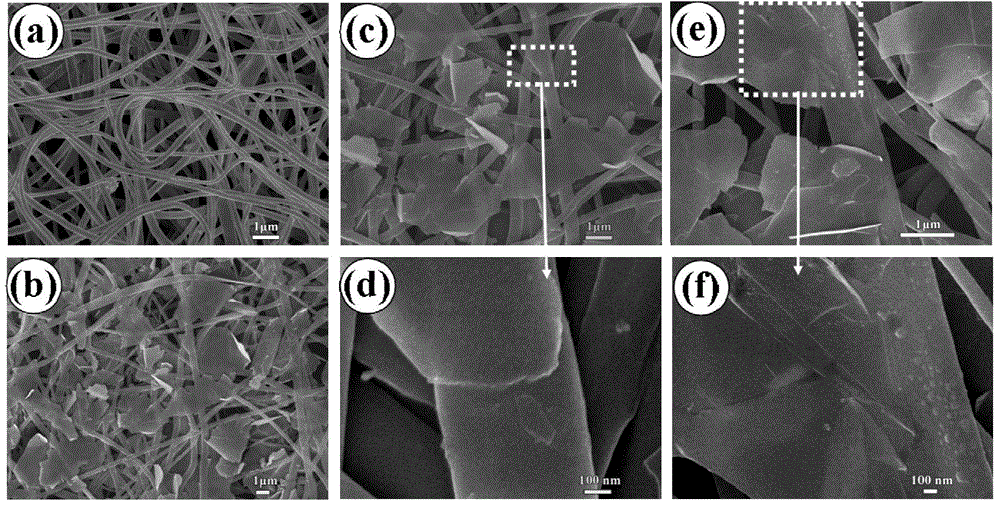

[0044] (2) Electrospinning: under the action of high-voltage static electricity, the PA6 solution obtained in step 1 will form a Taylor cone at the spinneret. When the electric field strength reaches a critical value, the electric field force can overcome the surface tension of the liquid. A charged jet stream is formed at the thread opening; during the jetting process, due to the rapid increase in the surface area of the jet stream, the solvent volatilizes, the fibers solidify and are arranged in disorder on the collecting device, thereby obtaining a fiber film with a thickness of 0.3-3 μm and an av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com