Electrochemical transducer based on graphene oxide and preparation method thereof

A graphene and electrochemical technology, applied in the field of graphene oxide-based electrochemical sensors and their preparation, can solve the problems of complex preparation process, inconvenient use, etc., and achieve the effect of fast detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

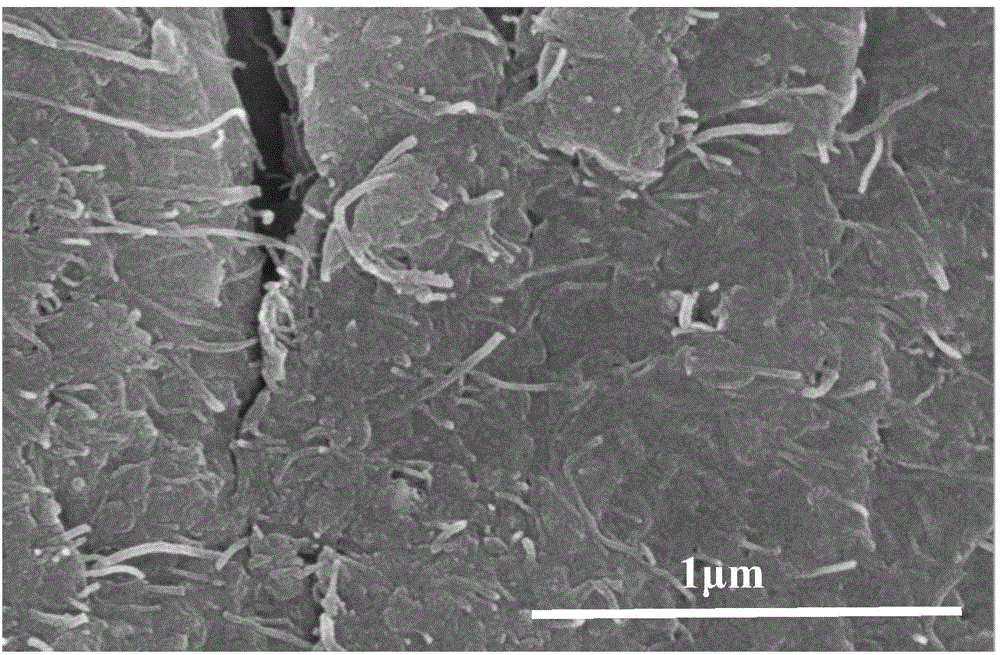

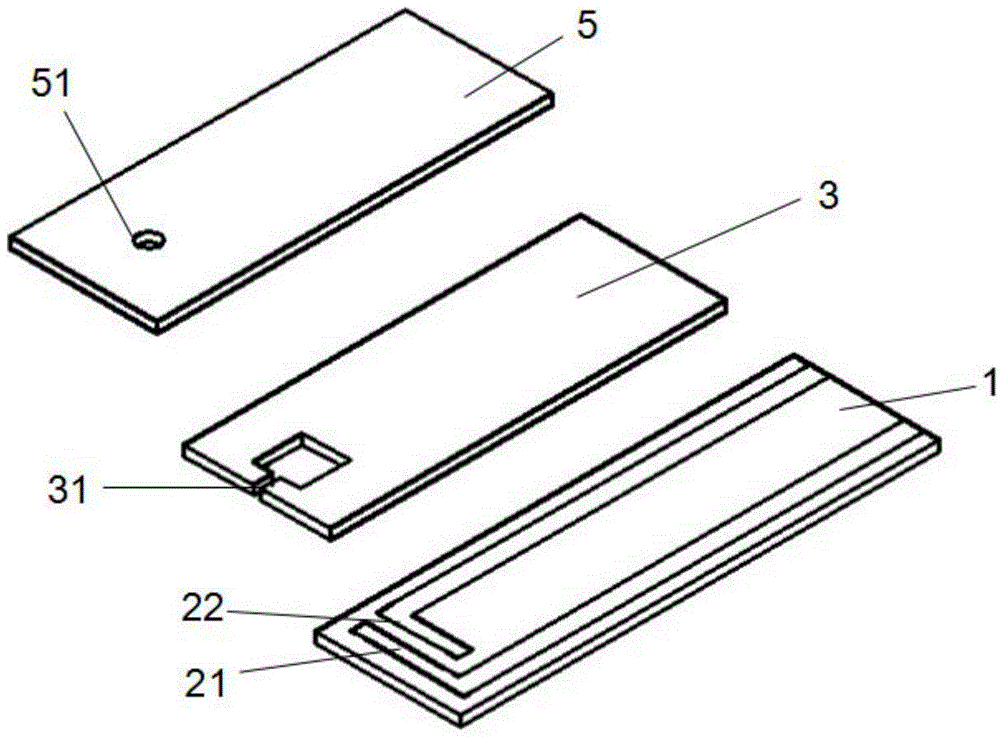

[0018] Graphene oxide was prepared by the Hummers method. Add 100mL of 98% concentrated sulfuric acid to a dry beaker, cool to 0°C with a low-temperature cooling liquid circulation pump, add 4g of natural flake graphite, 2.5g of sodium nitrate and 8g of potassium permanganate during stirring, and control the reaction temperature at Below 10°C, stir for 2h. Then place the beaker in a constant temperature water bath at about 35°C, and continue stirring for 30 minutes after the temperature of the reaction solution rises to 35°C. Finally, 200 mL of deionized water was added during stirring, the reaction temperature was controlled within 100° C., and stirring was continued for 30 min. Dilute the reaction solution to 500mL with deionized water, add an appropriate amount of 5% hydrogen peroxide solution, filter while hot, and wash thoroughly with 5% hydrochloric acid and deionized water until there is no SO in the filtrate 4 2- (with BaCl 2 The filtered supernatant is detected), ...

Embodiment 2

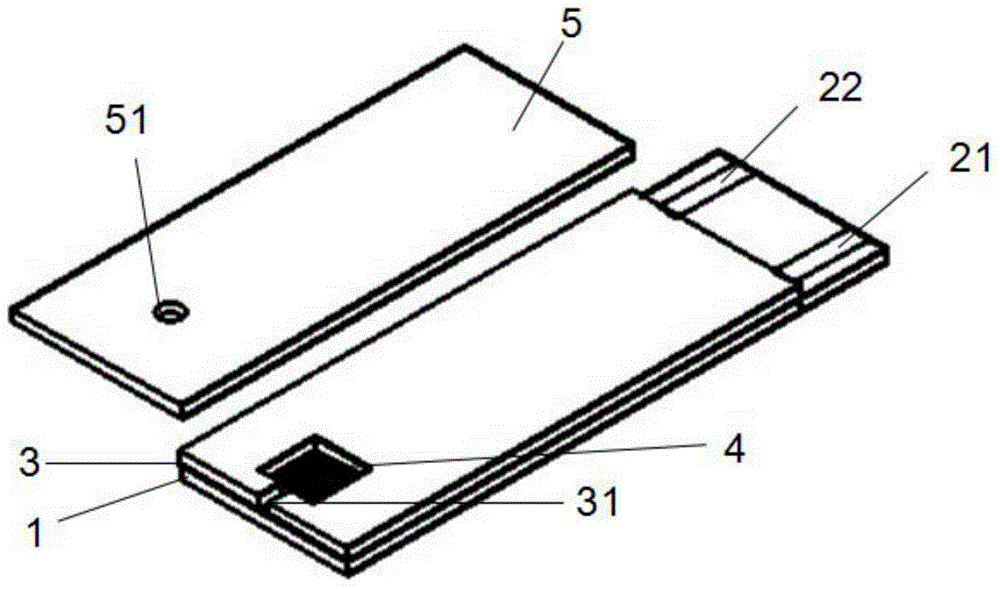

[0023] Embodiment 2 Adopt the method in embodiment 1 to prepare the electrochemical sensor based on graphene oxide, only difference is when preparing the aqueous solution of graphene oxide and glucose-specific enzyme, the pH value of described graphene oxide aqueous solution is adjusted to 7 . The relationship between the magnitude of the current between the working electrode 21 and the reference electrode 22 with the glucose concentration is as follows: Figure 4 shown. The relationship between the current and the glucose concentration is i(μA)=0.002C(mmol / L)+0.1309.

Embodiment 3

[0025] Embodiment 3 Adopt the method in embodiment 1 to prepare the electrochemical sensor based on graphene oxide, only difference is that when preparing the aqueous solution of graphene oxide and glucose-specific enzyme, the pH value of described graphene oxide aqueous solution is adjusted to 12 . The relationship between the magnitude of the current between the working electrode 21 and the reference electrode 22 with the glucose concentration is as follows: Figure 4 shown. The relationship between the current and the glucose concentration is i(μA)=0.0027 C(mmol / L)+0.2453.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com