Sugarcane Press Automatic Control System

An automatic control system and control system technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as uneven cane drop, inability to control accurately, troublesome installation, maintenance, and repair of nuclear scales, and achieve Improve the extraction rate of sugar, save the amount of permeate water, and eliminate the effects of nuclear radiation hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

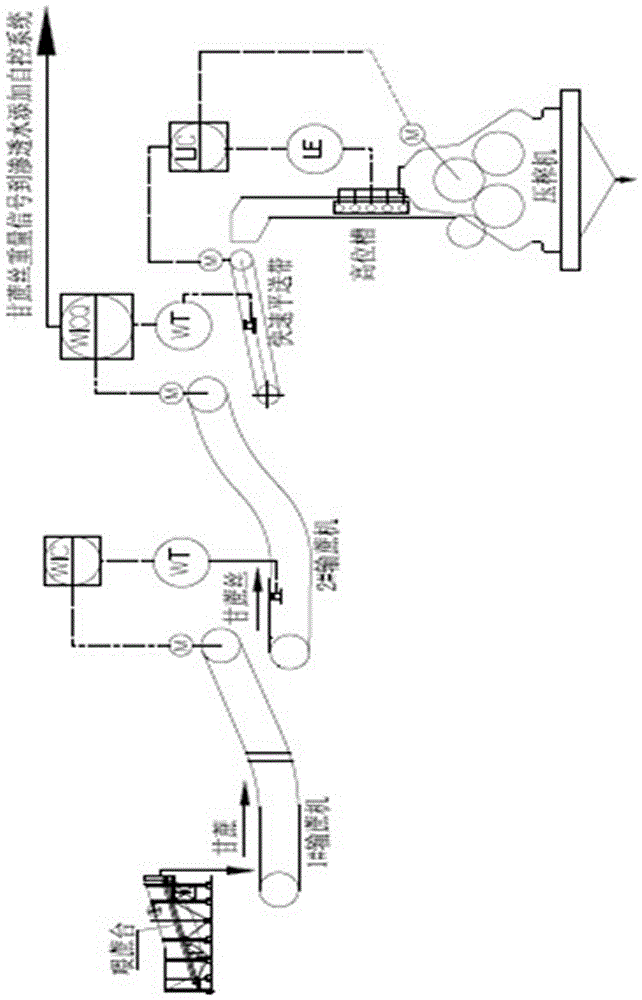

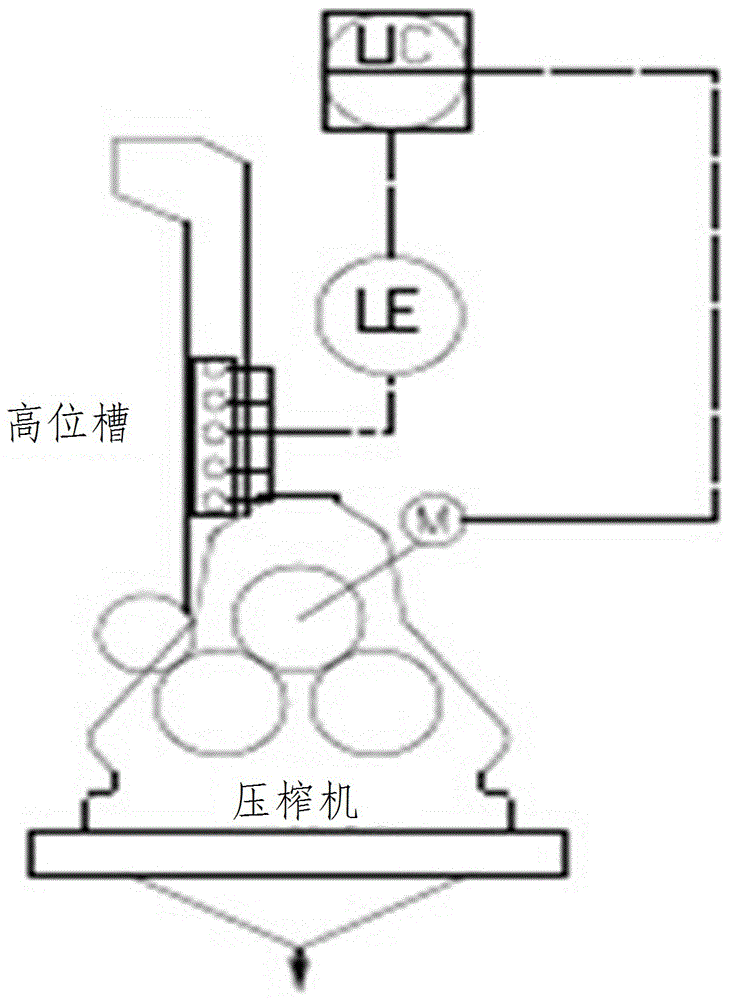

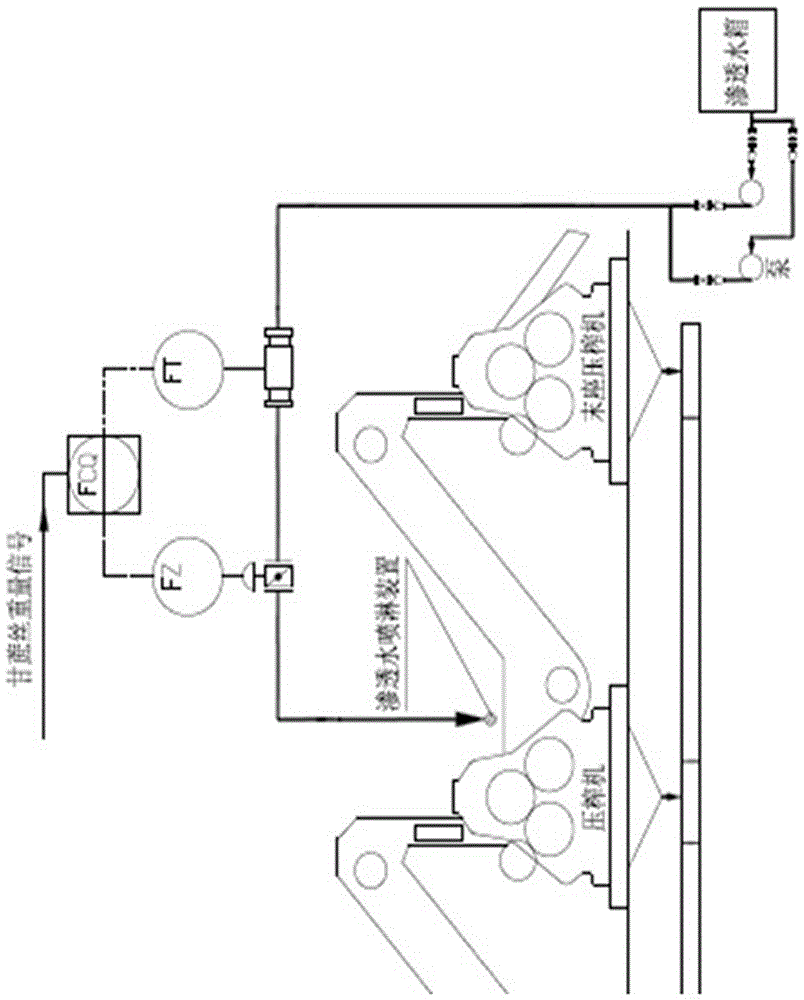

[0054] An automatic control system for sugarcane crushing, the main components of which include a weighing sensor, a material level sensor, an electromagnetic flowmeter, a DCS control system, and a control valve, including an automatic control system for a cane conveying belt, an automatic control system for a high level trough, and a permeate water The ratio automatic control system with the weight of sugarcane silk.

[0055]The described sugarcane belt automatic control system adopts the method of double weighing to measure the sugarcane shredded weight that goes into the squeeze, installs the weighing sensor at 2# cane conveying machine, measures the sugarcane shredded weight of 2# conveying sugarcane machine, DCS control system according to this The signal controls the speed of the 1# sugarcane conveyor, uniformly controls the amount of sugarcane silk on the 2# sugarcane conveyor; install a load cell on the fast conveyor belt to measure the weight of the sugarcane silk on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com