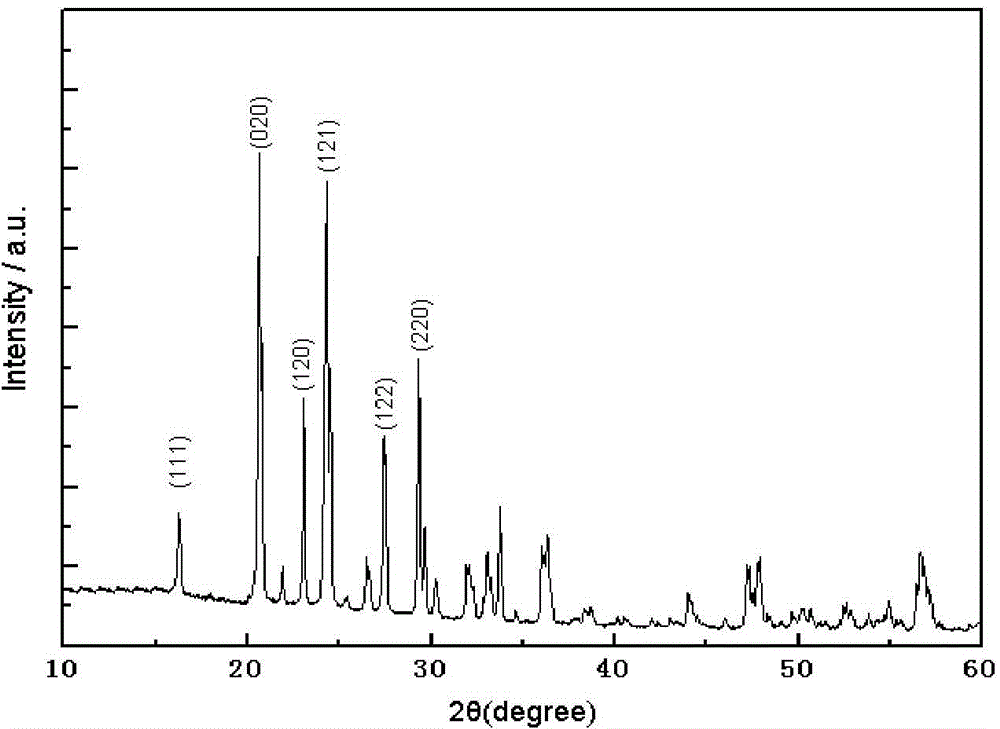

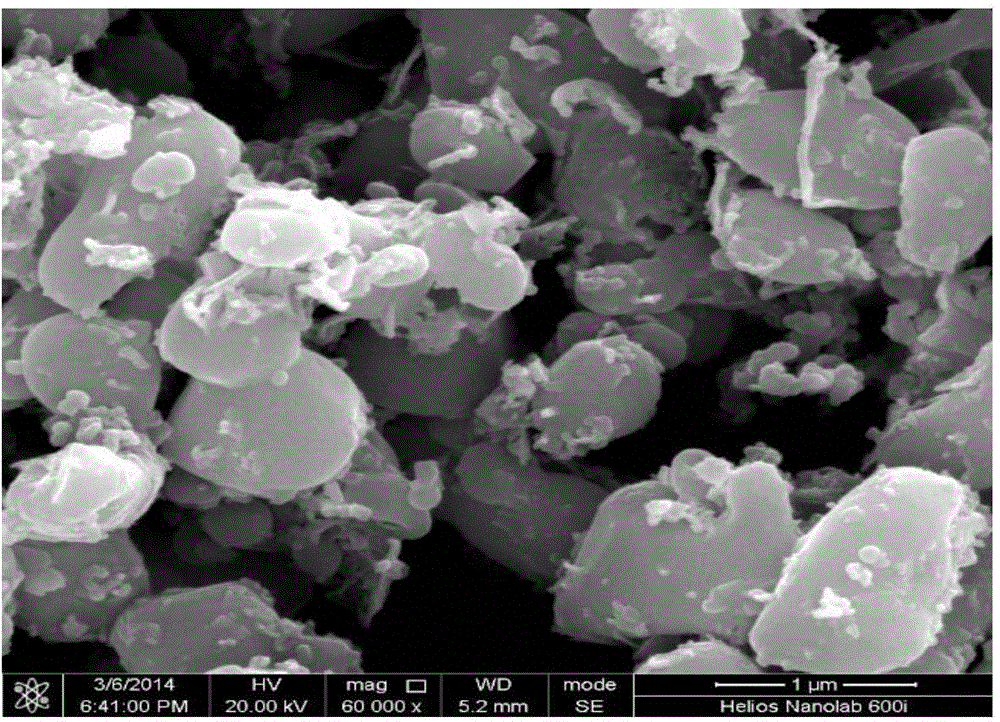

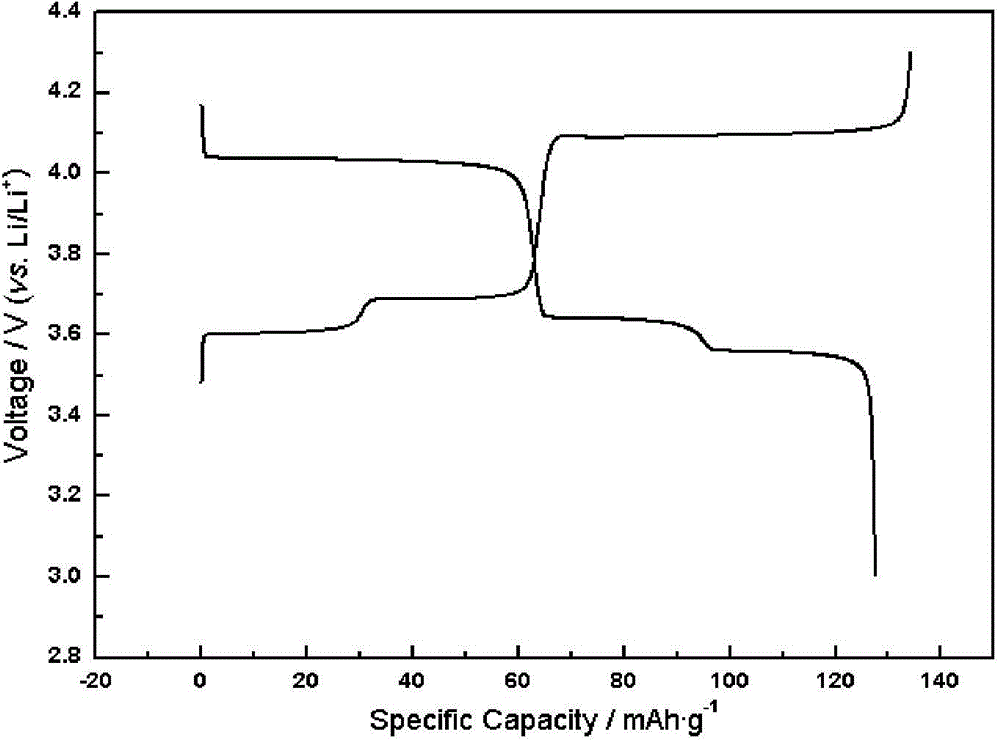

Preparation method of lithium ion battery positive electrode material Li3V2(PO4)3

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high synthesis temperature, long calcination time, and complicated sol-gel process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1: In this implementation mode, lithium-ion battery positive electrode material Li 3 V 2 (PO 4 ) 3 Prepared according to the following steps:

[0019] 1. Weigh lithium source, vanadium source, phosphorus source and carbon source materials according to the molar ratio of lithium element, vanadium element, phosphorus element and carbon element in the ratio of 3:2:3:(2.5~3), mix them, and then mix them in adding an aqueous hydrogen peroxide solution with a volume fraction of 30% for ball milling, and then drying to obtain a precursor;

[0020] 2. Put the precursor into a tube furnace, treat it at 300±50°C and an inert atmosphere for 4±0.5h, and then grind it to obtain the intermediate;

[0021] 3. Place the intermediate in an inert atmosphere, sinter at 800±50°C for 6±0.2h, and then cool to room temperature to obtain Li-ion battery anode material Li 3 V 2 (PO 4 ) 3 ;

[0022] Wherein, the ratio of the lithium element material to the aq...

specific Embodiment approach 2

[0026] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the time for ball milling in step 1 is 5-7 hours, and the rotating speed of the ball mill is 100-200 r / min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: the ball-to-material ratio in step 1 is 2:1. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com