Flue gas desulfurization and denitrification method and device and application of flue gas desulfurization and denitrification device

A desulfurization, denitrification, and flue gas technology, applied in the field of flue gas purification, can solve the problems of inability to realize desulfurization and denitrification reactions and process conditions, ineffective removal of dioxins, and ineffective use of heat, and reduce investment. and operating costs, reducing equipment and operating investment, and reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] see figure 2 , the present invention processes the flue gas through a flue gas treatment tower and an irradiation reactor respectively. The temperature of the flue gas produced by boiler 1 is 130°C, and the SO in the flue gas x The content is 300ppm, and the NOx content is 200ppm.

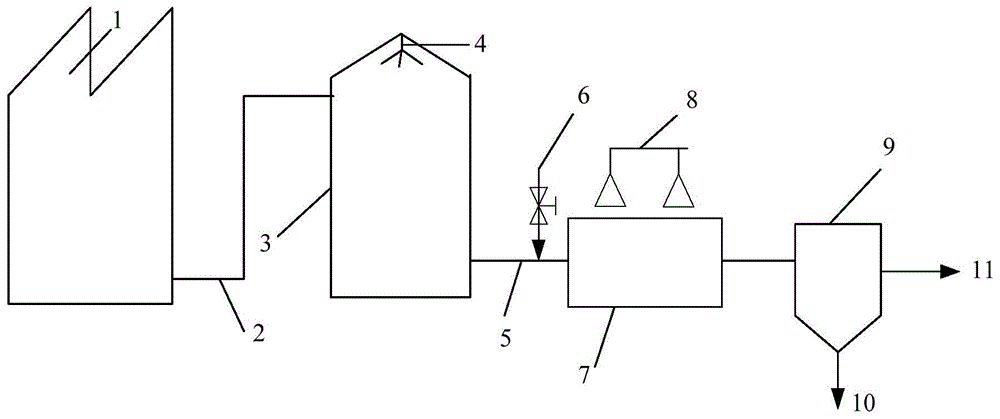

[0058] figure 2 The components and connections of the electron beam flue gas desulfurization and denitrification device shown are as follows:

[0059] The boiler 1 is connected to the flue gas treatment tower 3 through the first flue 2;

[0060] A flue gas treatment tower 3, a spray system 4 is installed on the flue gas treatment tower 3; the flue gas outlet of the flue gas treatment tower 3 is connected to the irradiation reactor 7 with a second flue 5, and the second flue 5 An ammonia injection control valve 6 is arranged on the top; an electron accelerator 8 is installed on the irradiation reactor 7, and an ultraviolet generator 9 is installed on the side wall of the irradiation rea...

Embodiment 2

[0067] see Figure 4 , the present invention processes the flue gas through a flue gas treatment tower and an irradiation reactor respectively. The flue gas temperature produced by boiler 1 is 150°C, the SOx content in the flue gas is 280ppm, and the NOx content is 200ppm.

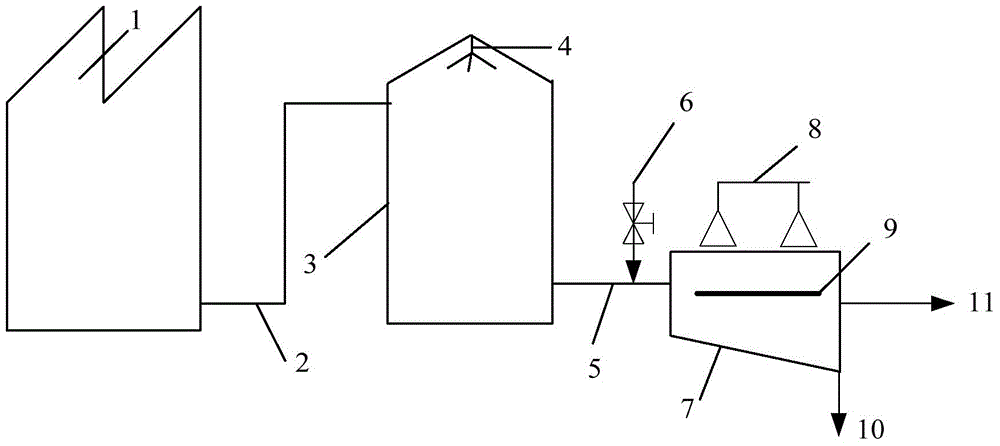

[0068] Figure 4 The components and connections of the flue gas desulfurization and denitrification device shown are as follows:

[0069] The boiler 1 is connected to the flue gas treatment tower 3 through the first flue 2; the flue gas treatment tower 3 is equipped with a spray system 4; the flue gas outlet of the flue gas treatment tower 3 passes through the second The flue 5 is connected to the inlet end of the irradiation reactor 7; the second flue 5 is provided with an ammonia injection control valve 6; the outlet end of the irradiation reactor 7 is connected to the first by-product collector 11; An electron accelerator 8 is installed above the irradiation reactor 7, an ultraviolet generator 9 is i...

Embodiment 3

[0075] see Figure 5, the present invention processes the flue gas through a flue gas treatment tower and an irradiation reactor respectively. The flue gas temperature produced by boiler 1 is 150°C, the SOx content in the flue gas is 280ppm, and the NOx content is 200ppm.

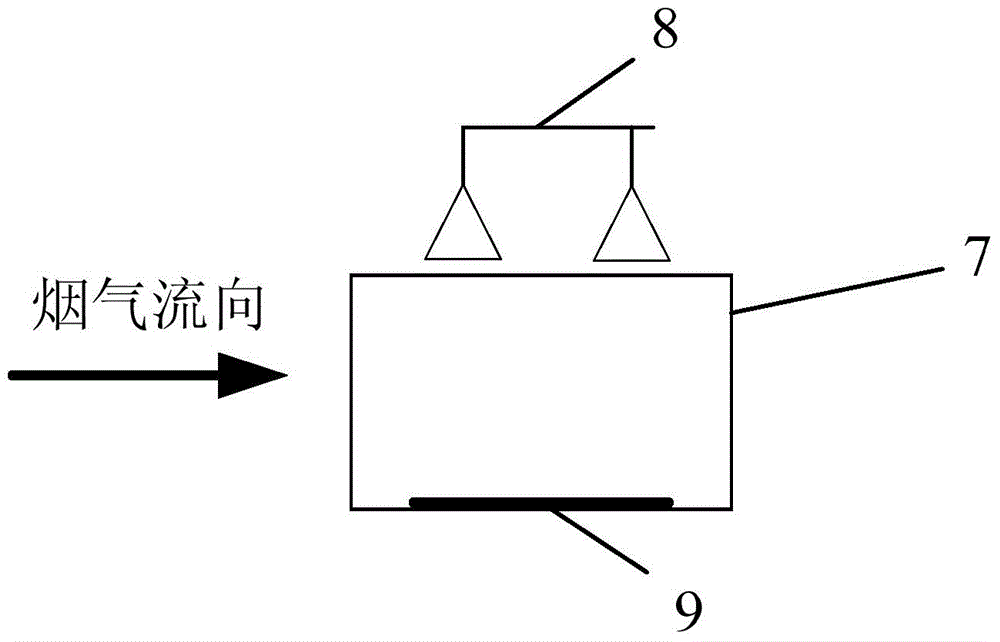

[0076] Figure 5 The components and connections of the shown flue gas desulfurization and denitrification device are similar to those in Example 2, specifically as follows:

[0077] The boiler 1 is connected to the flue gas treatment tower 3 through the first flue 2; the flue gas treatment tower 3 is equipped with a spray system 4; the flue gas outlet of the flue gas treatment tower 3 passes through the second The flue 5 is connected to the inlet of the irradiation reactor 7; the second flue 5 is provided with an ammonia injection control valve 6; the outlet of the irradiation reactor 7 is connected to the first by-product collector 11.

[0078] The ultraviolet generator in the irradiation reactor 7 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com