Silver-doped zirconium dioxide photocatalyst, and preparation method and application thereof

A technology of zirconium dioxide and photocatalyst, which is applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to achieve low production cost, reduce bandgap width, improve The effect of photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

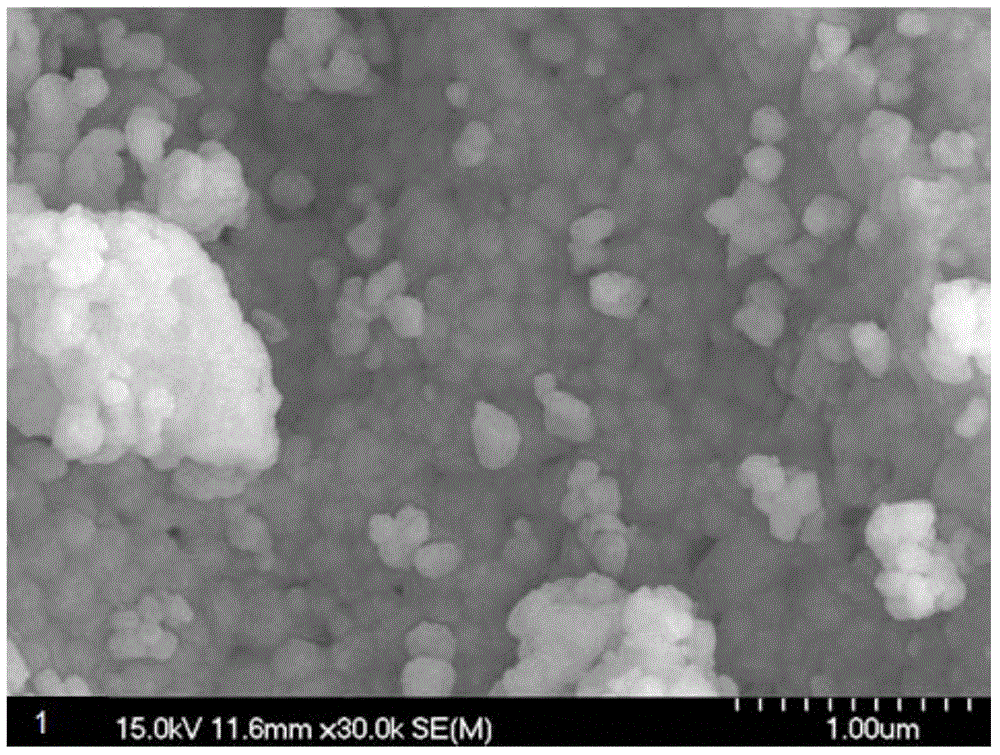

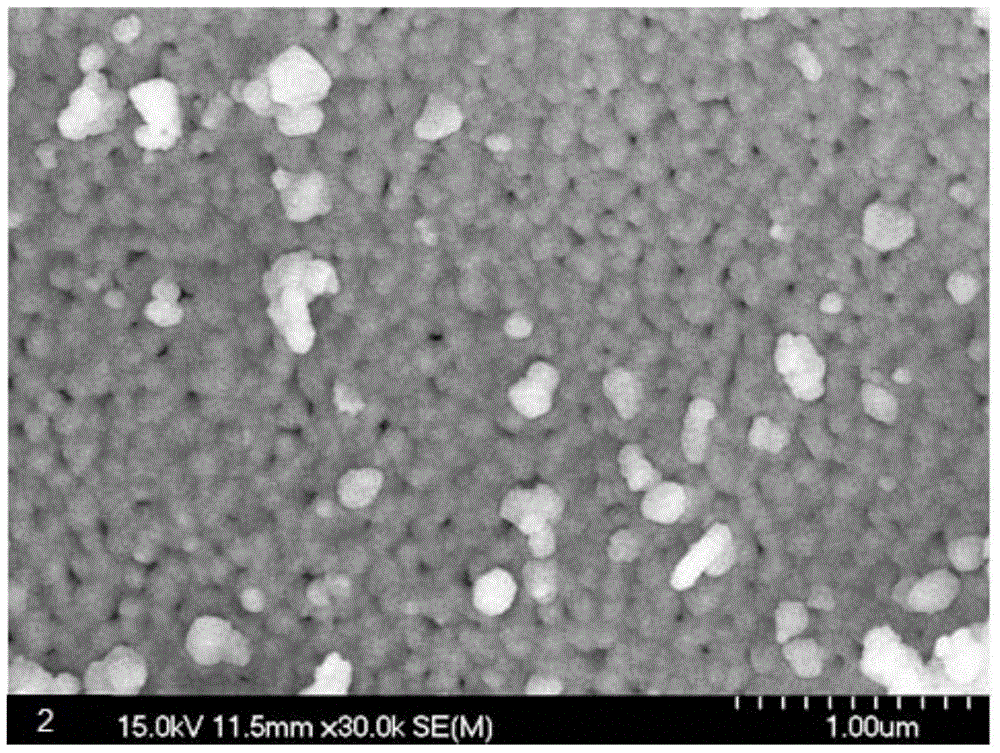

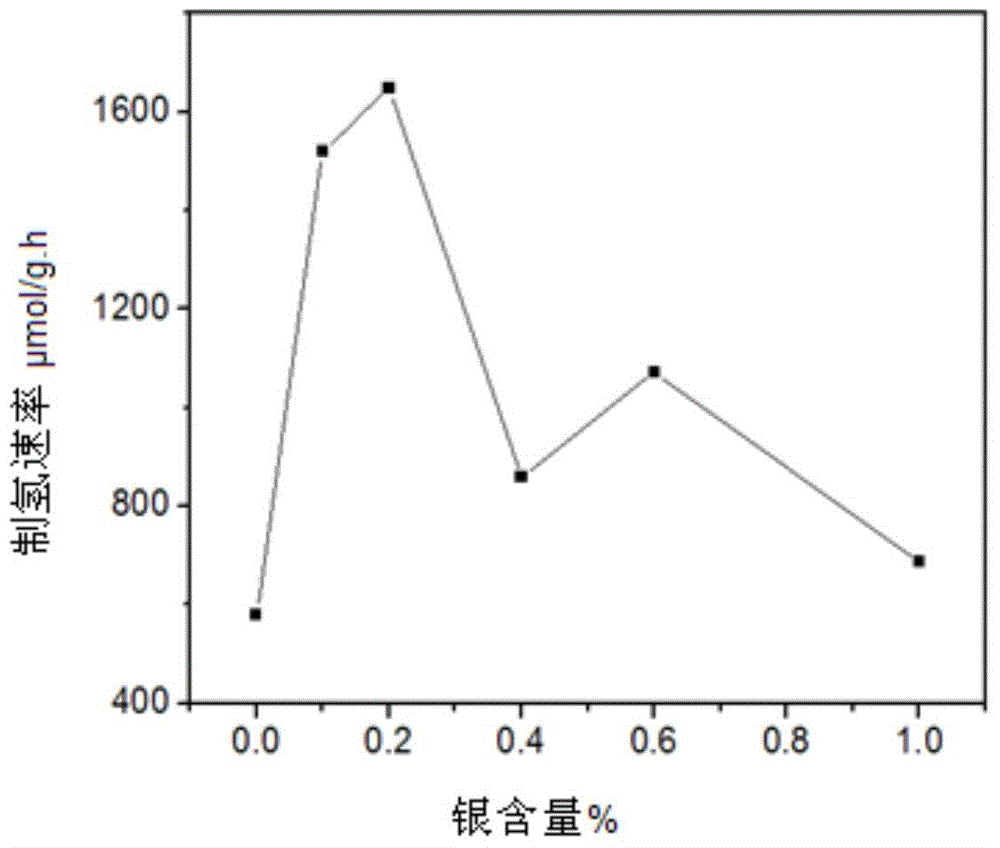

[0017] Take 6 parts of industrial grade zirconia 1.08g, put them into a muffle furnace, and calcinate at 450°C for 5h to obtain intermediate sample 1; put intermediate sample 1 into 10mL of 10mol / L NaOH solution and stir, drop Add 0.1mo / L of AgNO 3 solution, each part of AgNO 3 The dripping amount of the solution is calculated based on the mass fraction of silver in zirconia being 0%, 0.1%, 0.2%, 0.4%, 0.6%, and 1%, and the stirring is continued for 1h to obtain the intermediate sample 2; the intermediate sample 2 Put it in an autoclave, and conduct a hydrothermal reaction at 180°C for 24 hours to obtain an intermediate sample 3; then put the intermediate sample 3 into a centrifuge tube, wash with centrifugation until the pH value of the supernatant is 7, and dry it at room temperature to obtain different Silver-doped zirconia photocatalysts in silver-doped amounts. When the silver doping amount is 0%, that is, the silver-free zirconium dioxide photocatalyst, its particle si...

Embodiment 2

[0020] Take 4 parts of industrial grade zirconia 1.08g, put them into a muffle furnace, and calcinate at 300°C for 5h to obtain an intermediate sample 1; put the intermediate sample 1 into 10mL of 6mol / L NaOH solution and stir, drop Add 0.45mo / L of AgNO 3 solution, AgNO 3 The dripping amount of the solution is calculated based on the mass fraction of silver in zirconia being 0.2%. Continue to stir for 1 hour to obtain intermediate sample 2; , hydrothermal reaction at 180°C and 240°C for 48 hours to obtain intermediate sample 3; then put intermediate sample 3 into a centrifuge tube, centrifuge and wash until the pH value of the supernatant was 7, and dry it at room temperature to obtain different hydrothermal reaction samples. temperature of silver-doped zirconia photocatalysts. The hydrogen production capacity of silver-doped zirconia photocatalysts at different hydrothermal reaction temperatures was evaluated using the device and method in Example 1. The relationship betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com