Catalyst for producing synthesis gas by partial oxidation of methane and preparation method thereof

A technology for catalyst and synthesis gas, which is applied in the field of catalyst for partial oxidation of methane to synthesis gas and its preparation field, can solve the problems of complex catalyst preparation method and low space velocity, and achieves stable catalyst activity, simple preparation process, and improved catalyst performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

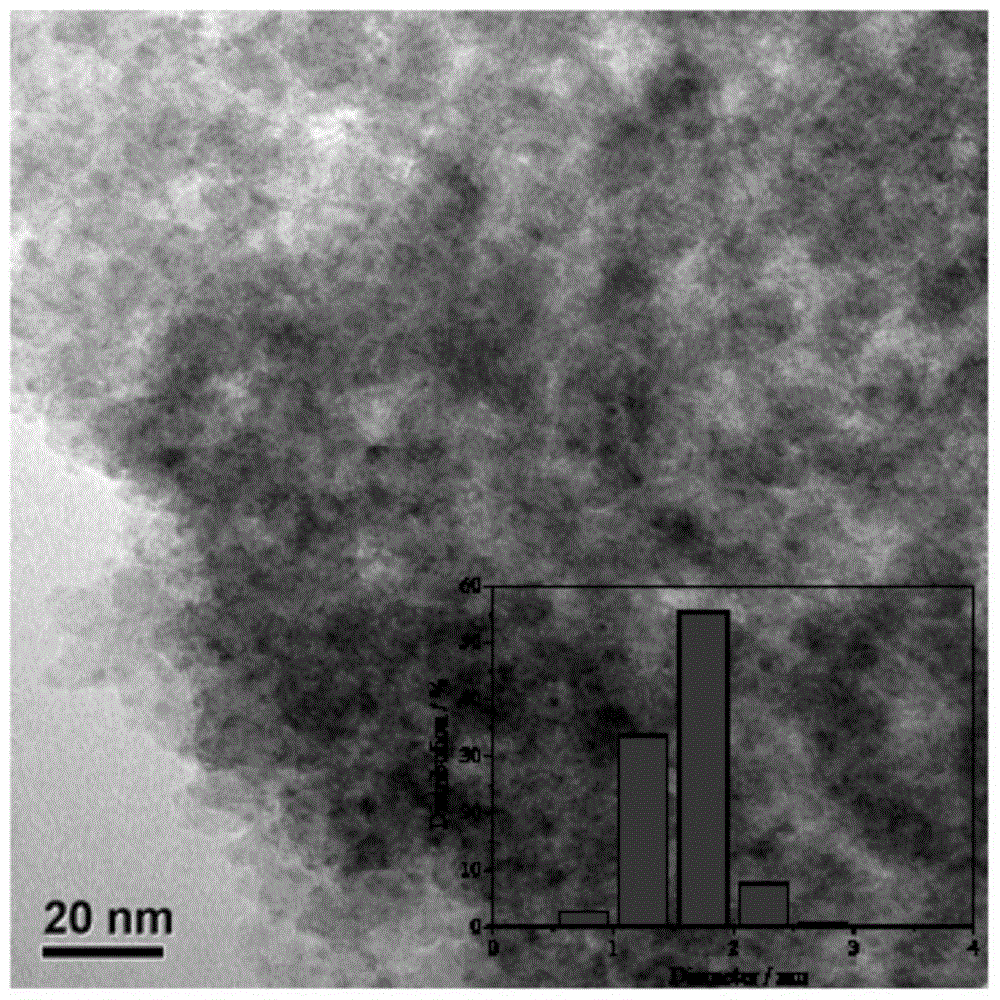

Image

Examples

Embodiment 1

[0019] Catalyst preparation: select 10g SiO 2 As a carrier, soak it in 20% nitric acid solution for 24 hours, wash it with distilled water until pH = 6.5-7.0, and dry it for later use; weigh 0.0098g of rhodium acetylacetonate and dissolve it in 20ml of acetylacetone solution, then weigh cerium acetylacetonate Dissolve 0.0763g in 60ml of acetylacetone, mix the two solvents to form a mixed impregnation solution, and weigh the treated SiO 2 Add 0.5g into the mixed impregnation solution for immersion for 24h, stir several times during the period, then evaporate the solution to dryness at 110°C, and roast in the air at 800°C for 2h with a heating rate of 1°C / min to obtain the catalyst 0.5%Rh-5%CeO 2 / SiO 2 .

[0020] Evaluation conditions: Before the reaction, the catalyst was reduced with hydrogen at 700°C for 1 hour. The reaction is carried out in a continuous sampling fixed-bed quartz reactor, the reaction temperature is 700°C, and the raw material gas is composed of CH 4 :O...

Embodiment 2

[0023] Catalyst preparation Referring to Example 1, the solvent is changed from acetylacetone to toluene, and the rest of the conditions are the same to obtain the catalyst 0.5%Rh-10%CeO 2 / SiO 2 The evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 1.

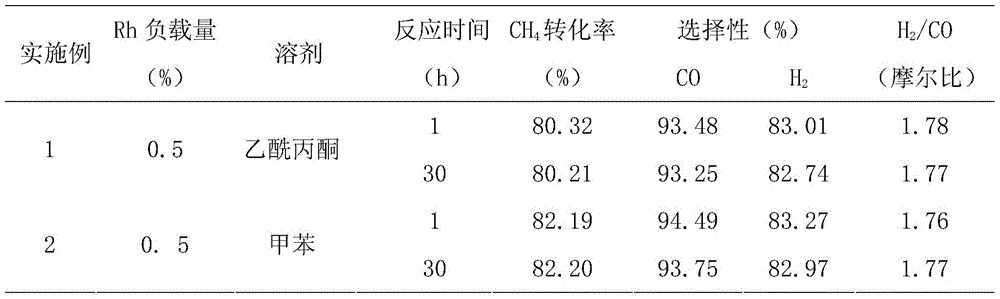

[0024] Table 1

[0025]

Embodiment 3~5

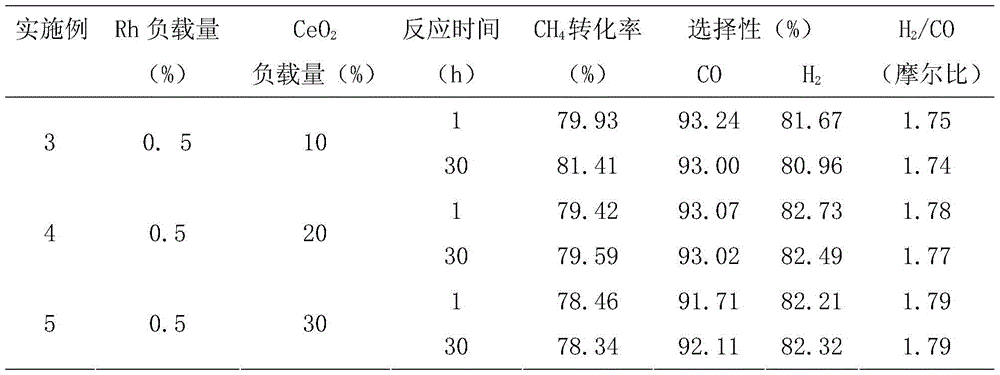

[0026] Examples 3-5: Catalyst preparation Referring to Example 1, the mass of cerium acetylacetonate was changed to 0.1525g, 0.3050g, and 0.4575g respectively, and the remaining conditions were the same to obtain a catalyst of 0.5%Rh-10%CeO 2 / SiO 2 , 0.5%Rh-20%CeO 2 / SiO 2 , 0.5%Rh-30%CeO 2 / SiO 2 . The evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 2.

[0027] Table 2

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com