Preparation method of nitrogen-doped graphene for cathode of lithium ion battery

A technology of nitrogen-doped graphene and lithium-ion batteries, which is applied in the field of preparation of nitrogen-doped graphene, can solve the problems of being unsuitable for large-scale production, graphene difficulties, and high temperature requirements, and achieves easy operation of preparation equipment, low price, and low energy consumption. short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

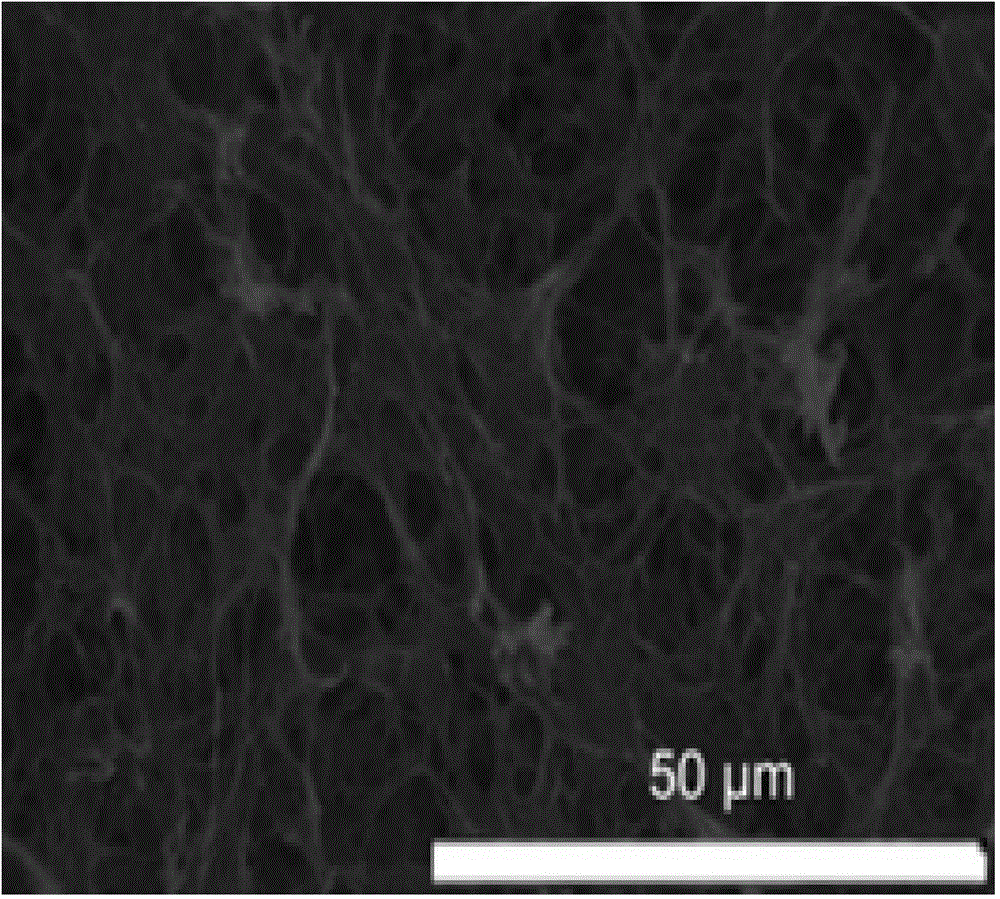

Embodiment 1

[0039] A method for preparing nitrogen-doped graphene for negative electrodes of lithium-ion batteries, comprising three processes: preparation of graphene oxide, reduction of graphene oxide, and preparation of nitrogen-doped graphene:

[0040] 1. The preparation process of graphene oxide

[0041] 1), 0.5 g of graphite powder and 1.5 g of potassium permanganate were added to 20 mL of concentrated sulfuric acid with a mass concentration of 98%, and uniformly stirred at 25° C., and then the entire reaction system was stirred at 60° C. for 2.5 hours;

[0042] 2), pour the mixture obtained after the reaction in step 1) into 200 mL of deionized water, continue to stir for 15 min, and then add 15 mL of hydrogen peroxide with a mass fraction of 30%;

[0043] 3), carry out suction filtration, wash away metal ions with the dilute hydrochloric acid that mass fraction is 15%, remove acid again with deionized water;

[0044] 4), adding the solid obtained in step 3) into 200mL deionized w...

Embodiment 2

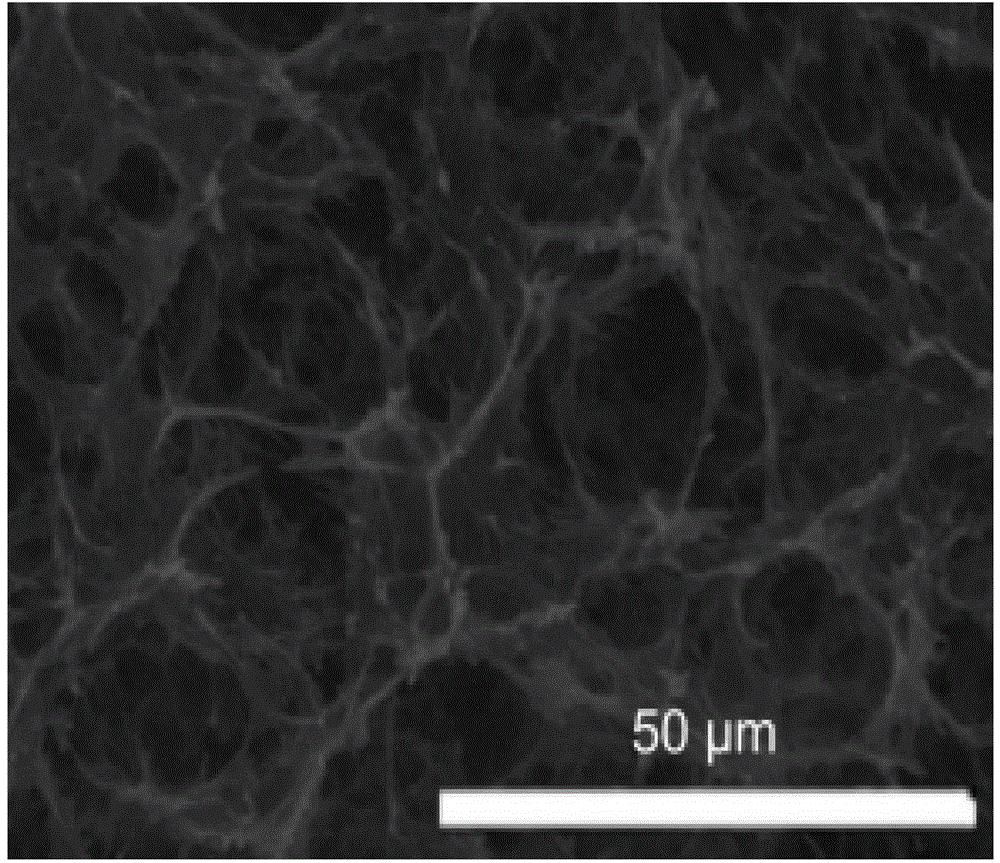

[0051] A method for preparing nitrogen-doped graphene for negative electrodes of lithium-ion batteries, comprising three processes of preparation of graphene oxide, reduction of graphene oxide and preparation of nitrogen-doped graphene, wherein the first two processes are the same as in Example 1, During the preparation of nitrogen-doped graphene, the graphene prepared by reducing graphene oxide is placed in a vacuum tube furnace and annealed at a high temperature under an ammonia atmosphere at 500 °C. The amount of nitrogen doped in the prepared nitrogen-doped graphene is 4.98at%, and the low current (45mA / g) reversible specific capacity is 827mAh / g.

Embodiment 3

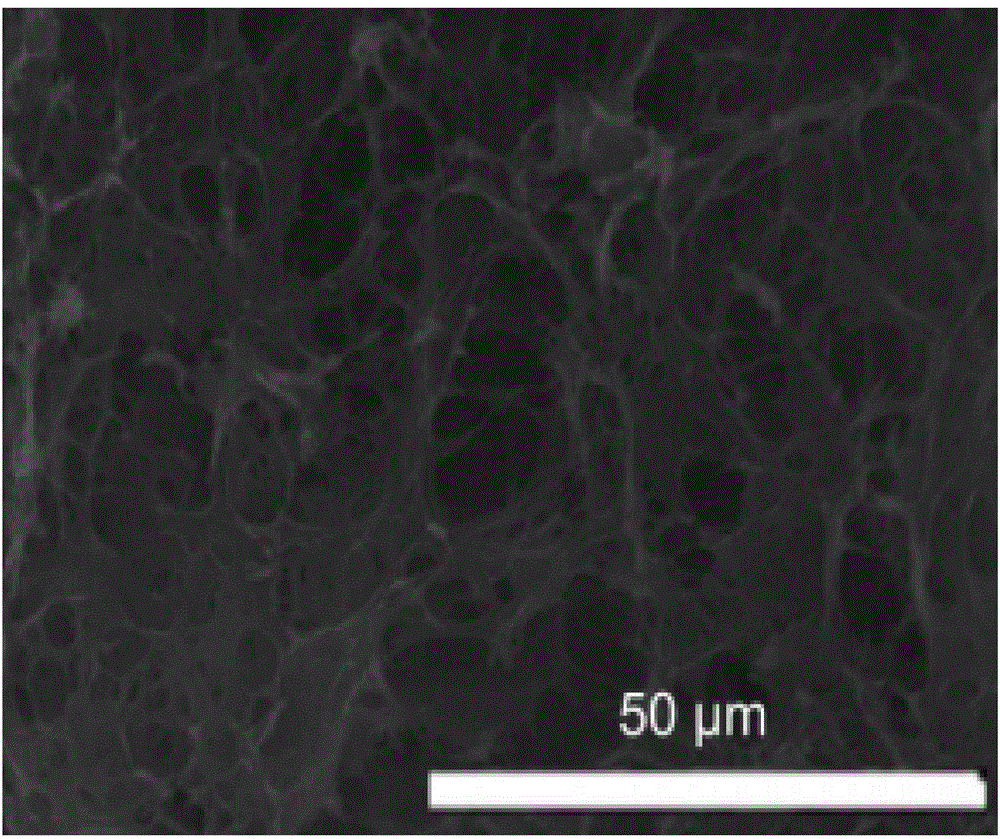

[0053] A method for preparing nitrogen-doped graphene for negative electrodes of lithium-ion batteries, comprising three processes of preparation of graphene oxide, reduction of graphene oxide and preparation of nitrogen-doped graphene, wherein the first two processes are the same as in Example 1, During the preparation of nitrogen-doped graphene, the graphene prepared by reducing graphene oxide is placed in a vacuum tube furnace and annealed at a high temperature under an ammonia atmosphere at 700 °C. The amount of nitrogen doped in the prepared nitrogen-doped graphene is 4.77at%, and the low current (45mA / g) reversible specific capacity is 790mAh / g.

[0054] The above three examples illustrate that the temperature of 500°C is not enough for nitrogen ions and graphene decomposed from ammonia to completely generate carbon-nitrogen bonds; and the reason for the low amount of nitrogen doping at 700°C is that nitrogen doping is more likely to occur in defects or graphene Edge, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com