Method for extracting lithium carbonate from coal ashes

A technology of fly ash and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, etc., to reduce pollution and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

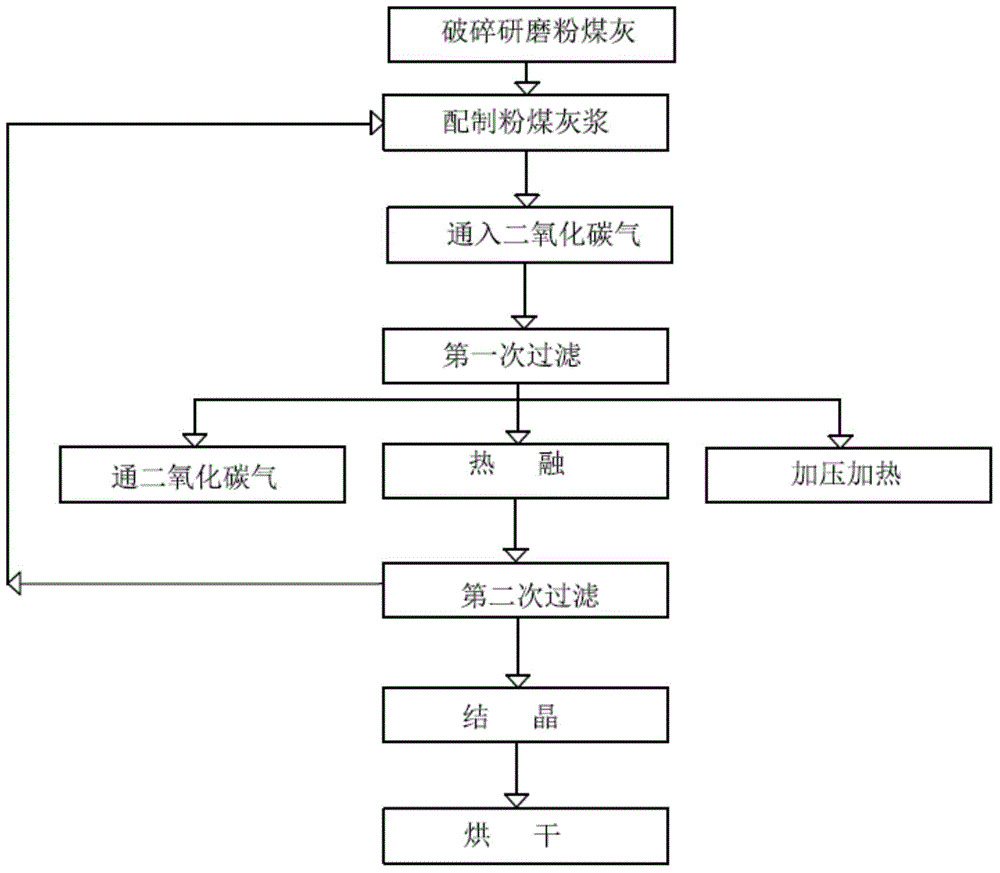

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 Shown, the invention provides a kind of method extracting lithium carbonate from fly ash, described method may further comprise the steps:

[0025] Step 1: Grinding and grinding the fly ash filter cake after extracting alumina, activated carbon, iron oxide and sodium silicate, the fineness of the grinding particles ranges from 100 mesh to 200 mesh to obtain fly ash powder, and the powder The coal ash powder is put into the reaction kettle, mixed according to the ratio of fly ash to water mass ratio of 1:2 and stirred evenly to obtain fly ash slurry;

[0026] Step 2: After sealing the fly ash slurry obtained in the step 1 in the reaction kettle, feed carbon dioxide gas, ventilate for 1 to 3 hours, and then deflate to obtain a lithium bicarbonate mixed solution;

[0027] Step 3: filtering the lithium bicarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com