Method for extracting ethyl linolenate from blackberry seed oil

A technology of ethyl linolenate and blackberry seeds, applied in the separation/purification of carboxylic acid esters, preparation of carboxylic acid esters, chemical instruments and methods, etc., can solve the problems of product efficacy loss, complicated process, solvent residue, etc., and achieve extraction Shorter time, simplified process flow, no harmful residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

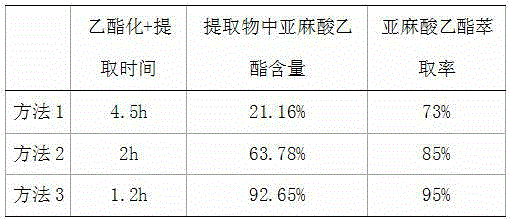

Examples

Embodiment 1

[0017] Embodiment 1, a kind of method of extracting ethyl linolenate from blackberry seed oil, its steps are as follows:

[0018] (1) Mix blackberry seed oil, absolute ethanol, and sodium ethylate in a mass ratio of 1:0.6:0.01 and put them into an extraction kettle. Adjust the temperature of the extraction kettle to 45°C and the pressure to 25 Mpa, and react for 1.5 hours;

[0019] (2) Adjust the temperature of the extraction device to reach the set process parameters, where: the extraction temperature is 30°C, and the rectification temperature gradient is T 1 40℃, T 2 50℃, T 3 60℃, T 4 80°C;

[0020] (3) Adjust the pressure of the extraction device to reach the set process parameters, where the extraction pressure is 20MPa and the rectification pressure is 10MPa, and the extraction starts;

[0021] (4) Turn on the ultrasonic device at the same time, and the electric power of the ultrasonic wave generated in each liter of the extraction kettle is 200W; extract ethyl linole...

Embodiment 2

[0022] Embodiment 2, a kind of method for extracting ethyl linolenate from blackberry seed oil, its steps are as follows:

[0023] (1) Mix blackberry seed oil, absolute ethanol, and sodium ethylate in a mass ratio of 1:0.8:0.03 and put them into an extraction kettle, adjust the temperature of the extraction kettle to 55°C and the pressure to 35 Mpa, and react for 2.5 hours;

[0024] (2) Adjust the temperature of the extraction device to reach the set process parameters, where: the extraction temperature is 50°C, and the rectification temperature gradient is T 1 50℃, T 2 60℃, T 3 70℃, T 4 80°C;

[0025] (3) Adjust the pressure of the extraction device to reach the set process parameters, where the extraction pressure is 35MPa and the rectification pressure is 18Mpa, and the extraction starts;

[0026] (4) Turn on the ultrasonic device at the same time, and the electric power of the ultrasonic wave generated in each liter of the extraction kettle is 500W; extract ethyl linol...

Embodiment 3

[0027] Embodiment 3, a kind of method for extracting ethyl linolenate from blackberry seed oil, its steps are as follows:

[0028] (1) Mix blackberry seed oil, absolute ethanol, and sodium ethylate in a mass ratio of 1:0.7:0.02 and put them into an extraction kettle. Adjust the temperature of the extraction kettle to 50°C and the pressure to 30 Mpa, and react for 2 hours;

[0029] (2) Adjust the temperature of the extraction device to reach the set process parameters, where: the extraction temperature is 40°C, and the rectification temperature is set to T 1 45°C, T 2 55°C, T 3 70℃, T 4 85°C.

[0030] (3) Adjust the pressure of the extraction device to reach the set process parameters, where the extraction pressure is 30MPa and the rectification pressure is 14Mpa, and the extraction starts;

[0031] (4) Turn on the ultrasonic device at the same time, and the electric power of the ultrasonic wave generated in each liter of the extraction kettle is 350W; extract ethyl linolen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com