Large-scale continuous weaving system for high-voltage static knitting polyimide nanofibers

A nanofiber, polyimide technology for chemical characterization of fibers, textile and paper, textile/flexible product manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

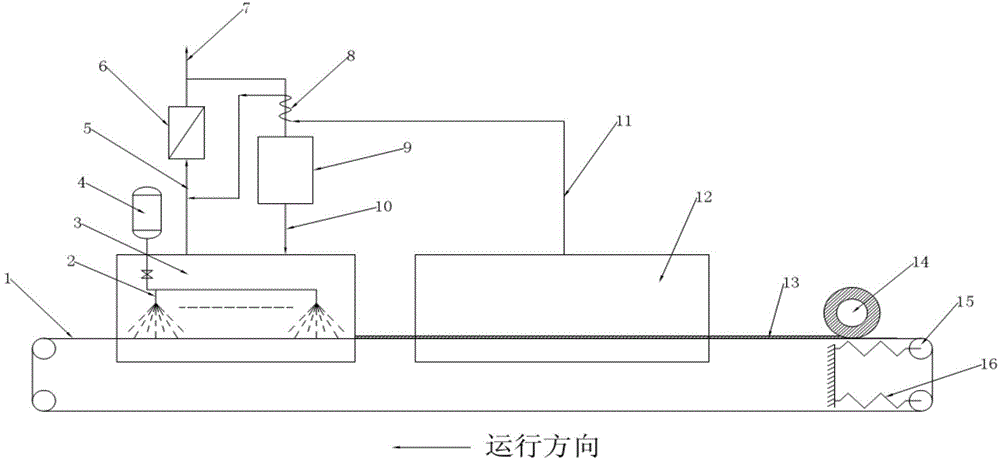

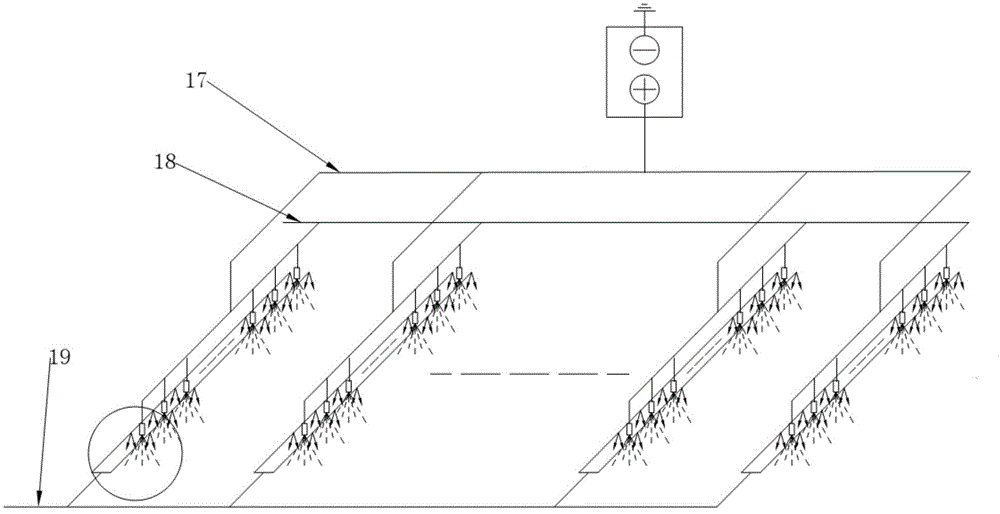

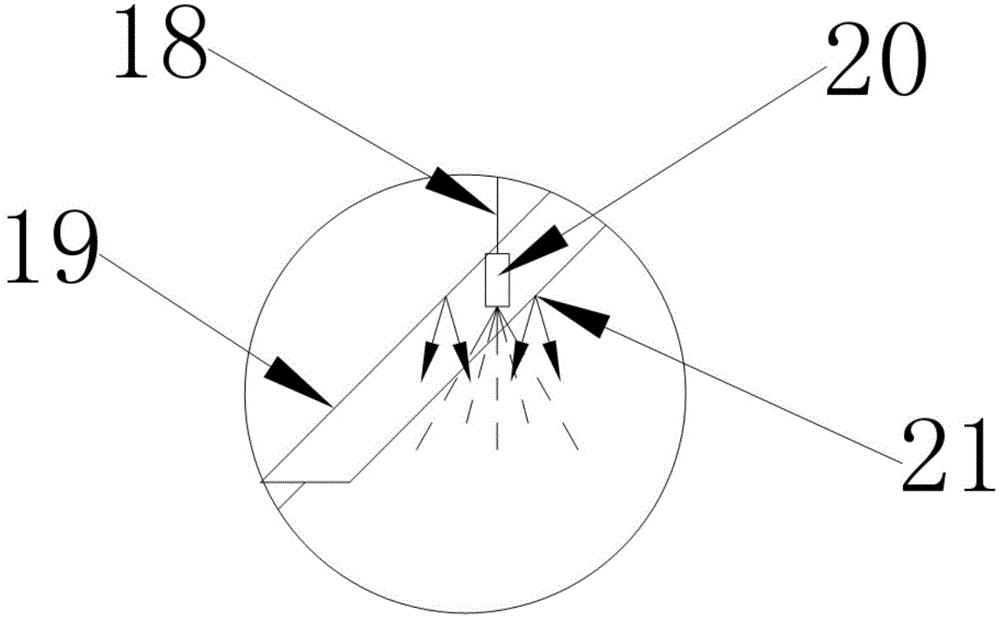

[0052] Example 1: Large-scale continuous weaving of polyimide nanofiber nonwovens

[0053] In this example, the spinning part is equipped with a space length of 20m and a width of 1.5m; the spinning part is equipped with 40 spinning modules, each module is 0.15m in width and 1.0m in length, and the interval between modules is 0.25m; The module is equipped with 30 5-needle nozzles; 40 spinning modules share a 250-liter spinning liquid storage tank and a set of flow control system; the circular conveyor belt in the product delivery system has a circumference of 92m and a width of 1.2m; the high-temperature electric furnace is 15m long , the width is 1.5m; the length of the winding part (including the transmission part) is 4.0m. The whole weaving system has a total length of 45.0 meters. The spinning part is equipped with a space length of 18m and a width of 1.5m. The specific implementation steps are as follows:

[0054] 1. Turn on the constant temperature and humidity system...

Embodiment 2

[0059] Embodiment Two: Large-scale continuous weaving of nylon 66 nanofiber nonwovens

[0060] In this example, the spinning part is equipped with a space length of 20m and a width of 1.5m; the spinning part is equipped with 40 spinning modules, each module is 0.15m in width and 1.0m in length, and the interval between modules is 0.25m; The module is equipped with 30 5-needle nozzles; 40 spinning modules share a 250-liter spinning liquid storage tank and a set of flow control system; the circular conveyor belt in the product delivery system has a circumference of 92m and a width of 1.2m; the high-temperature electric furnace is 15m long , the width is 1.5m; the length of the winding part (including the transmission part) is 4.0m. The whole weaving system has a total length of 45.0 meters. The spinning part is equipped with a space length of 18m and a width of 1.5m. The specific implementation steps are as follows:

[0061] 1. Turn on the constant temperature and humidity sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com