Direct drive independent variable pitch tidal current energy electric generation hydraulic turbine

A technology of independent pitch change and tidal current energy, applied in ocean energy power generation, reaction engine, hydroelectric power generation, etc., can solve the problem of difficult adjustment of bevel gear and blade bevel gear gap, inaccurate blade pitch angle transformation, and large volume of impeller hub and other problems, to achieve the effect of improving the strength of the main shaft, compact structure, and reducing the volume of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

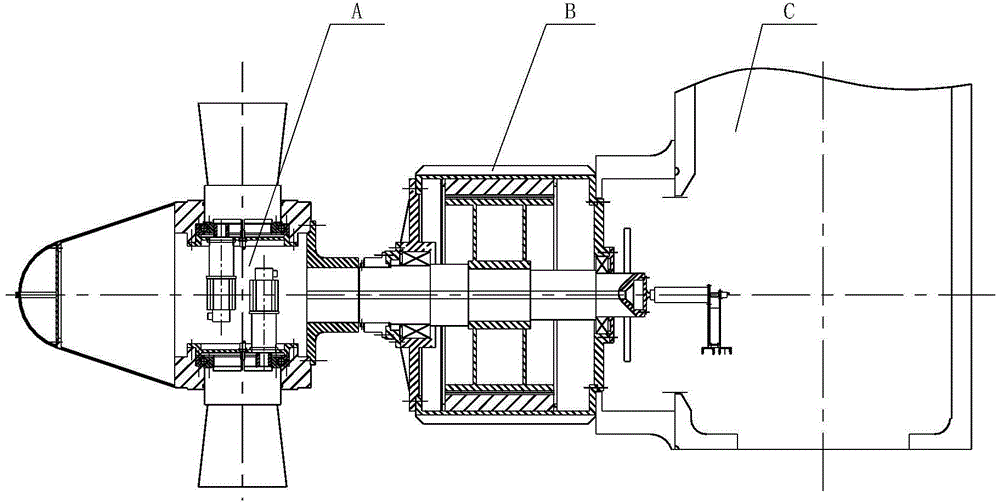

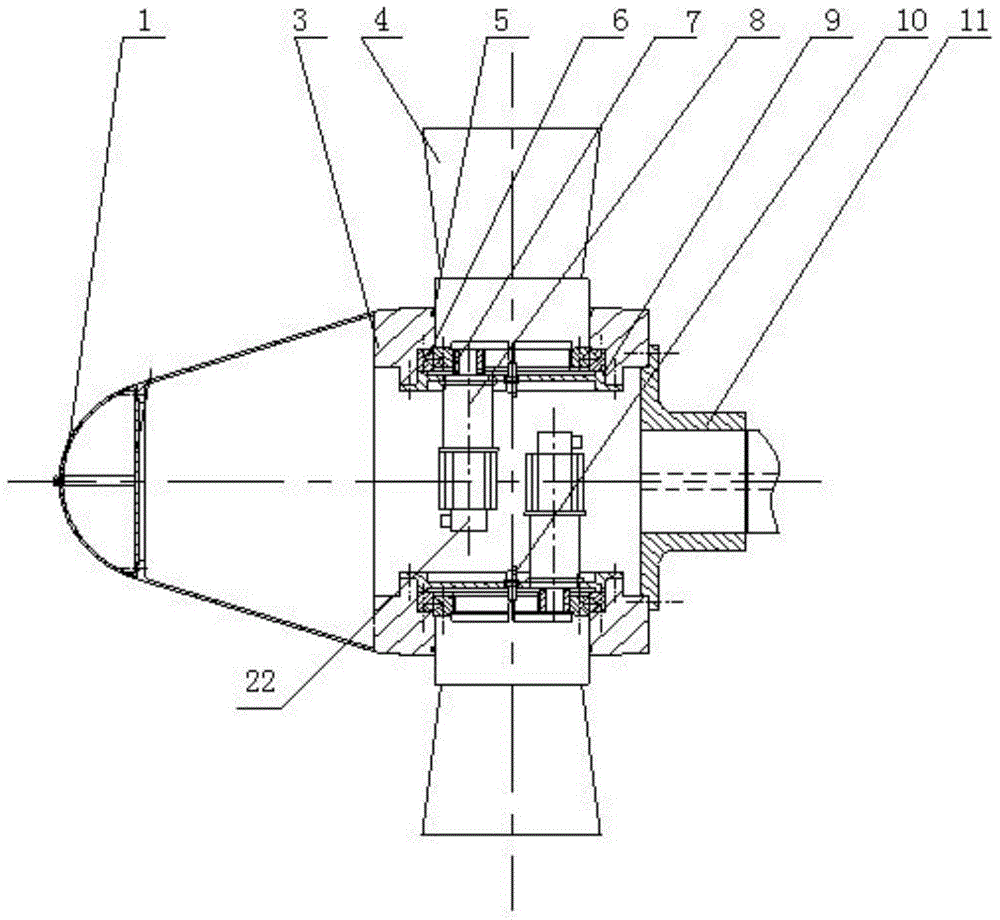

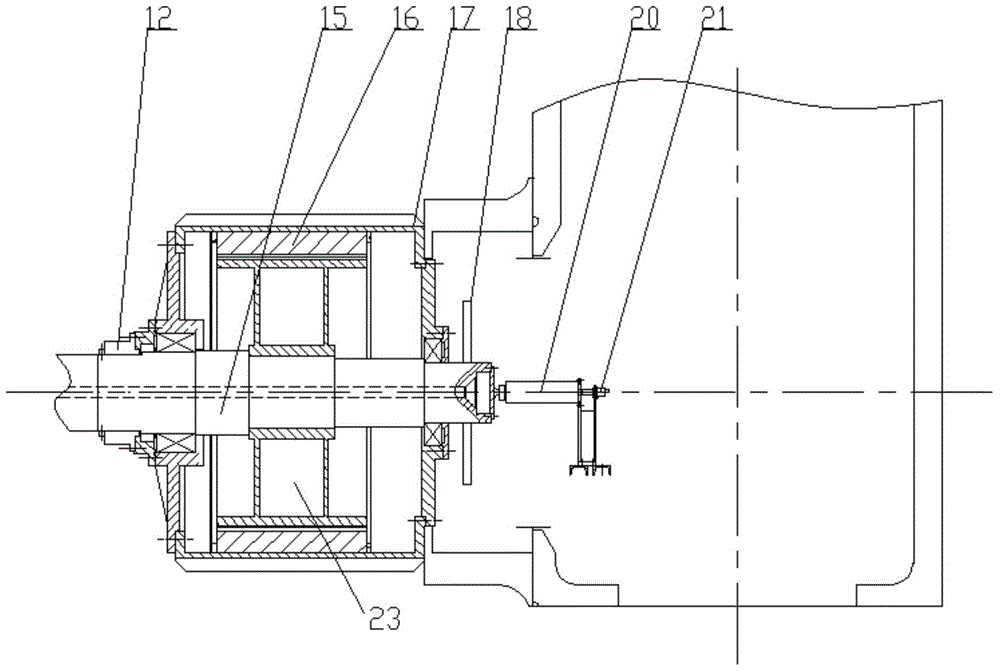

[0014] combine figure 1 , figure 2 and image 3 , the present invention includes an impeller A, a generator B and a tower C, specifically a fairing 1, a hub 3 fixedly connected to the fairing 1, blades 4 evenly arranged on the hub 3, and a flange 11 connected to the The generator B fixedly connected to the hub 3 and the tower C fixedly connected to the generator B also include an internal gear bearing 6, the bottom end of the root of the blade 4 is fixedly connected to the inner ring of the internal gear bearing 6, and the internal gear The outer ring of the type bearing 6 is fixedly connected with the wheel hub 3, the lower end of the internal gear bearing 6 is fixedly connected to the chassis 9, the lower end of the chassis 9 is equipped with a pitch motor 8, the lower end of the pitch motor 8 is provided with a pitch motor encod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com