High temperature and high pressure spring safety valve with thermal compensation and elastic compensation sealing surface

An elastic compensation, high temperature and high pressure technology, applied in safety valves, lifting valves, balance valves, etc., can solve problems such as easy cracks, achieve reliable work, good thermal compensation and elastic compensation capabilities, and delay the effect of front leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

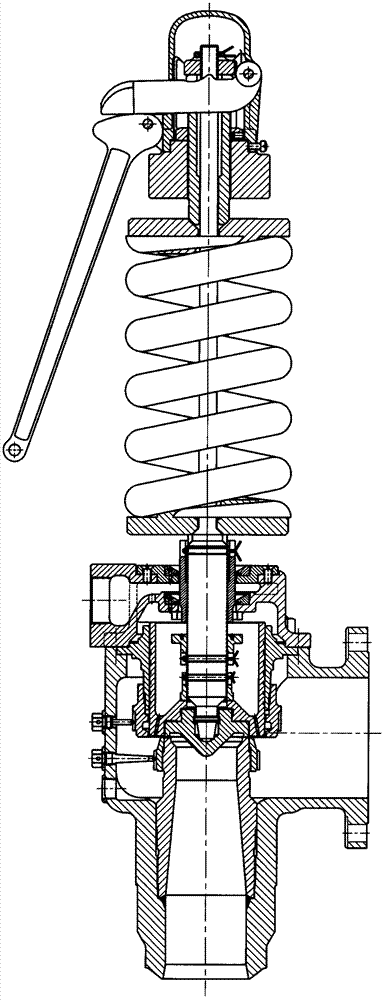

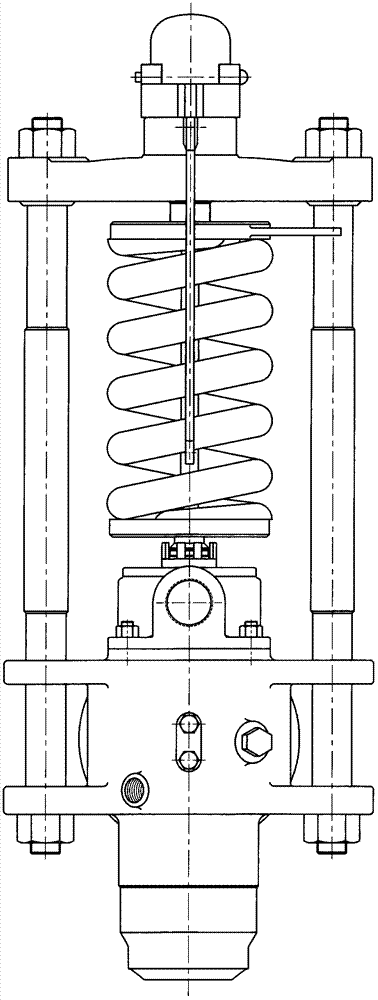

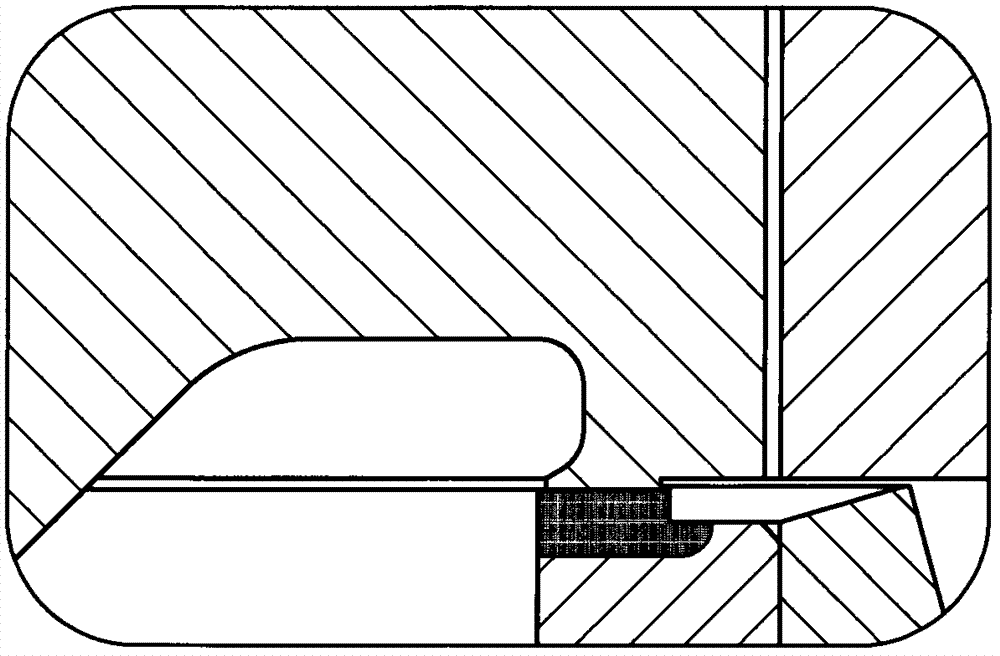

[0046] like Image 6 Shown is a schematic diagram of the product structure of the high temperature and high pressure spring safety valve according to the embodiment of the present invention.

[0047] The safety valve is installed at the outlet of the superheater of the 300MW subcritical unit, and is used for the discharge and depressurization when the primary steam is overpressured. Valve operating temperature: 540℃, nominal diameter DN: inlet 75 / outlet 200, set pressure: 18.0~21.0MPa, valve body material: WC6, valve disc body material: F22, hot disc material: Inconel 718, nozzle sealing surface Material: Stellite 12. The valve is a full-scale safety valve with a large discharge coefficient. It adopts the upper and lower double adjustment rings to control and adjust the valve's jumping and returning; The back pressure regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com