Graphene composite material and preparation method thereof

A composite material, graphene technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, electrical components, etc., can solve the problem of sacrificing the overall film light transmittance, reducing square resistance, graphene scratch resistance and ultrasonic cleaning. Problems that have not been greatly improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The application also provides a kind of preparation method of graphene composite material, comprises the following steps:

[0026] Mix the conductive substance with the resin precursor to obtain a mixture;

[0027] The mixture is coated on the surface of the graphene composited on the surface of the substrate, and then cured to obtain a graphene composite material.

[0028] In the process of preparing the graphene composite material, the applicant firstly mixes the conductive substance and the resin precursor, the mixture of the conductive substance and the resin precursor. In order to uniformly mix the conductive substance and the resin precursor, the present application preferably adopts ultrasonic treatment to uniformly mix the conductive substance and the resin precursor. The time of the ultrasonic treatment is preferably 1 s-24 h, more preferably 10 min-60 min.

[0029] After the mixture of the conductive substance and the resin precursor is obtained, the mixture...

Embodiment 1

[0033] 1) ultrasonically treat the adhesive and ITO powder, so that the oxide conductive particles are evenly distributed in the adhesive; the ratio of conductive particles to precursor is 0.1g / ml;

[0034] 2) The target product obtained in step 1) is coated on the surface of the graphene to be protected by spin coating; the graphene is prepared on the PET surface by CVD; after drying for 3h, a vertically conductive graphite is formed on the graphene surface Oxygen protective film, the protective film has ultra-high transparency and strong weather resistance.

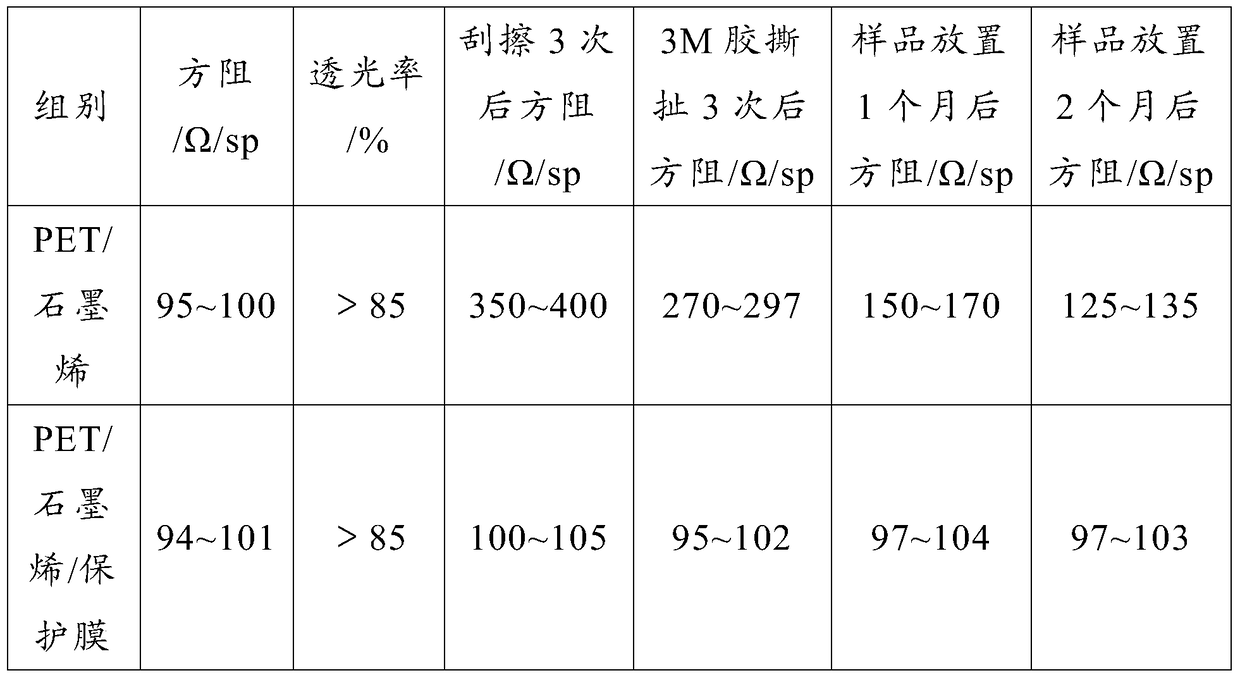

[0035] The graphene with protective film prepared in this embodiment is compared with the graphene without protective film, and the relevant data are shown in Table 1.

[0036] Table 1 present embodiment has the performance contrast data table of protective film and graphene without protective film

[0037]

Embodiment 2

[0039] 1) Ultrasonic treatment of Loctite UV photocurable adhesive and Ag nanowires, so that the metal conductive particles are evenly distributed in the adhesive; the ratio of conductive particles to precursor is 0.2g / ml;

[0040] 2) The target product obtained in step 1) is sprayed on the surface of graphene to be protected; graphene is prepared on the PET surface by epitaxy; at a total energy of 1000mJ / cm 2 After UV curing to form a film, a vertically conductive graphene protective film will be formed on the graphene surface. The protective film has ultra-high transparency and strong weather resistance.

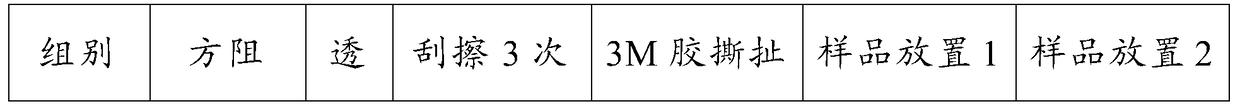

[0041] The properties of the graphene with and without the protective film were compared and tested, and the relevant data are shown in Table 2.

[0042] Table 2 present embodiment has protective film and the performance contrast data table of the graphene that does not have protective film

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com