Annexing agent and method for improving upper flue-cured tobacco leaf quality in tobacco leaf production link

A production link and additive technology, applied in the field of tobacco, can solve the problems of poor quality of upper smoke, low utilization rate, limited effect, etc., and achieve the effect of low cost, simple use and operation, and weakened alkaline smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of invert sugar: Weigh 15 grams of sucrose, add 18 grams of water, 0.4 grams of edible phosphoric acid, and stir continuously at 120°C until it turns brown.

[0036] Preparation of acidic aqueous solution containing invert sugar: Take the above-mentioned invert sugar hot solution, add 0.6 g of edible phosphoric acid, dilute to 200 g with water, stir well and filter for later use. At this time, the sugar concentration of the acidic aqueous solution is about 7.5%, and the pH value is about 1.9.

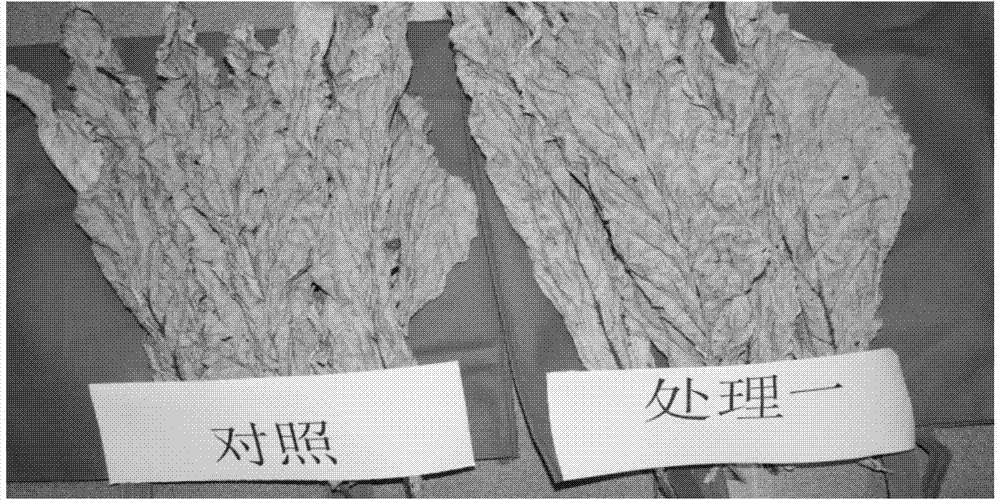

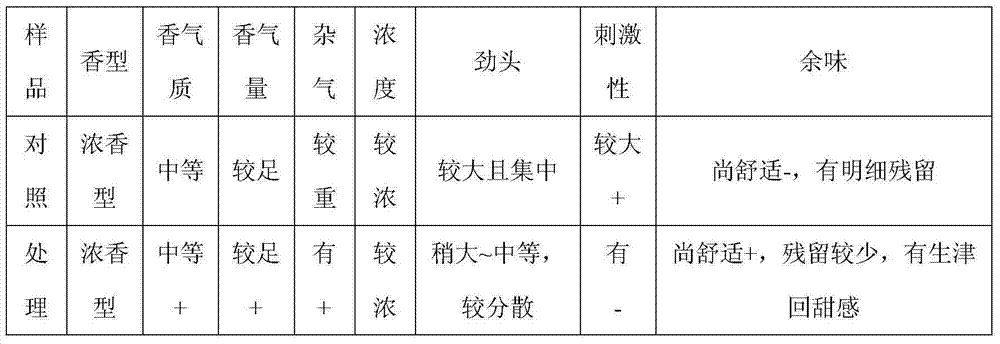

[0037] How to use it on the upper tobacco leaves: In the production area of Zhangjiajie, Hunan, 40 mature upper tobacco leaves are harvested normally, and the above-mentioned prepared acidic aqueous solution containing invert sugar is evenly sprayed on the front and back of the above-mentioned just-harvested tobacco leaves with a small spray device Both sides are then installed in the same tobacco oven as the control, and are baked according to conventional technique...

Embodiment 2

[0045] Preparation of invert sugar: Weigh 300 grams of sucrose, add 360 grams of water, 8 grams of edible phosphoric acid, and stir continuously at 120°C until it turns brown.

[0046] Preparation of an acidic aqueous solution containing invert sugar: take the above invert sugar hot solution, add 12 grams of edible phosphoric acid, dilute to 4000 grams with water, stir well and filter for later use. At this time, the sugar concentration of the acidic aqueous solution is about 7.5%, and the pH value is about 1.9.

[0047] How to use it on the upper part of flue-cured tobacco: Spray the above-mentioned acidic aqueous solution containing invert sugar evenly with an agricultural sprayer on the upper part of 120 trees in the Zhangjiajie production area of Hunan Province with only 6-7 upper leaves left two days before ripening. The front and back sides of the tobacco leaves are harvested two days later, and put into the same barn as the control at the same time, and are roasted an...

Embodiment 3

[0056] 1. Material preparation

[0057] Preparation of invert sugar: Weigh 90 grams of sucrose, add 108 grams of water, 2.4 grams of edible phosphoric acid, and stir continuously at 120°C until it turns brown.

[0058] Preparation of an acidic aqueous solution containing invert sugar: take the hot invert sugar solution, add 3.6 grams of edible phosphoric acid, dilute to 1200 g with water, stir well and filter for later use.

[0059] Other reagents: glacial acetic acid (acetic acid), glucose, fructose, and xylose were all purchased analytically pure.

[0060] 2. Method

[0061] Using the single factor test method, in the same flue-cured tobacco field in Zhangjiajie, Hunan Province (the total nitrogen application rate of the tobacco field is 8.5kg, the ratio of nitrogen, phosphorus and potassium is 1:1.2:2.6, and the row-to-plant spacing is 1.1m×0.5m), according to Table 3 For the treatment conditions, 40 mature flue-cured tobacco leaves with only the upper 6 leaves were selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com