A kind of ultra-high sensitivity noble metal-modified zno micro-nano hierarchical structure and its preparation method

A hierarchical structure, precious metal technology, applied in chemical instruments and methods, analytical materials, other chemical processes, etc., can solve problems such as insufficient sensitivity, and achieve the effect of improving sensitivity, improving adsorption capacity, increasing sensitivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Synthesis of ZnO micro-nano hierarchical structure: 1 g of zinc acetate (Zn(CH 3 COO) 2 ) and 4g urea (CO(NH 2 ) 2 ) was dissolved in 40ml of a mixed solvent composed of deionized water and ethylene glycol in a volume ratio of 3:1, stirred to form a transparent solution; then transferred to a sealed Erlenmeyer flask and placed in an oven at a temperature of 90ºC and keep warm for 10h; then centrifuge to separate the white precipitate, wash it 2-3 times with deionized water, put it into a 60ºC vacuum drying oven to dry the ZnO precursor; finally put the dried ZnO precursor in a 400ºC horse Annealing in a Furnace or a tube furnace can obtain a ZnO micro-nano hierarchical structure composed of ultra-thin single-crystal porous ZnO nanosheets.

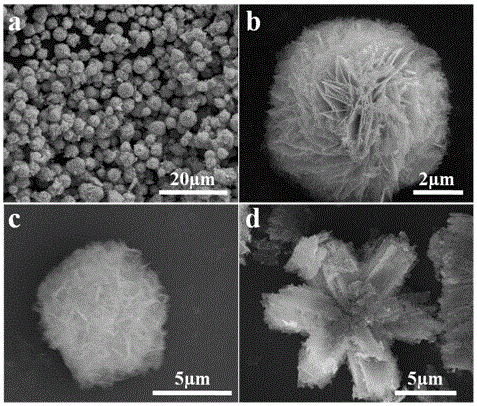

[0043] The ZnO micro-nano hierarchical structure prepared in this embodiment is as follows figure 1 As shown in 1d, its shape is flower-like.

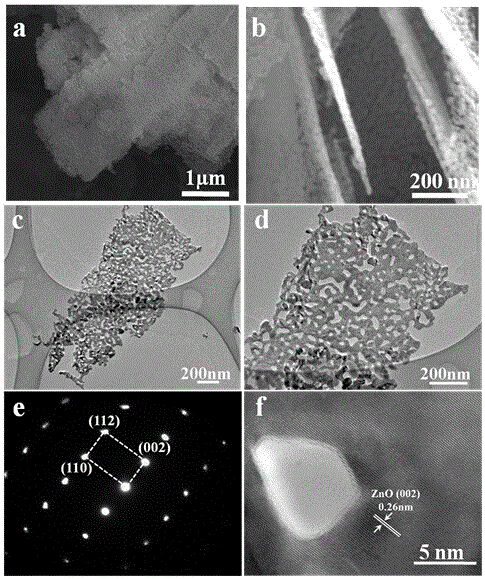

[0044] In addition, the scanning electron microscope images and electron diffrac...

Embodiment 2

[0052] (1) Synthesis of ZnO micro-nano hierarchical structure: 0.5 g of zinc acetate (Zn(CH 3 COO) 2 ) and 3g urea (CO(NH 2 ) 2 ) was dissolved in 50ml of a mixed solvent consisting of deionized water and ethylene glycol at a volume ratio of 1:1, stirred for 3 minutes to form a transparent solution; then transferred to a sealed Erlenmeyer flask, and placed in a In the oven, keep warm for 8h; then use centrifugation to separate the obtained white precipitate from the solution, and wash it with deionized water for 2-3 times, then put it into a 60ºC vacuum drying oven to dry to obtain the ZnO precursor; finally put The dried ZnO precursor is annealed at 300ºC to obtain the following figure 1 In the spherical ZnO micro-nano hierarchical structure shown in 1c, the ultra-thin single-crystal porous ZnO nanosheets are about 2 µm in length, 400 nm in width, and 8 nm in thickness, and the nanoholes are evenly distributed throughout the nanosheet.

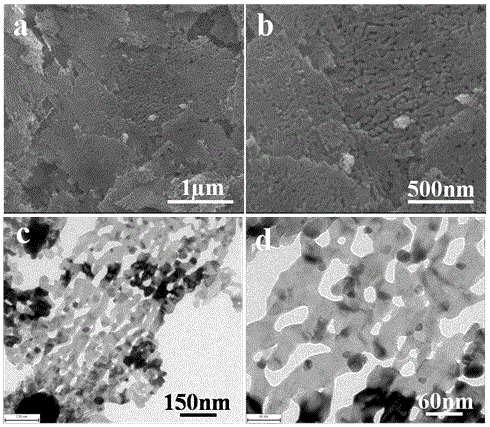

[0053] (2) Modification of ZnO mic...

Embodiment 3

[0057] (1) Synthesis of ZnO micro-nano hierarchical structure: 0.5 g of zinc acetate (Zn(CH 3 COO) 2 ) and 1g urea (CO(NH 2 ) 2 ) was dissolved in 40ml of a mixed solvent composed of deionized water and ethylene glycol in a volume ratio of 1:1, stirred to form a transparent solution, and then transferred to a sealed Erlenmeyer flask and placed in an oven at a temperature of 75ºC and keep it warm for 5 hours; then use centrifugation to separate the obtained white precipitate from the solution, wash it with deionized water for 2-3 times, and then put it into a 60ºC vacuum oven to dry to obtain the ZnO precursor; finally dry The ZnO precursor is annealed at 300ºC to get the following figure 1 In the spherical ZnO micro-nano hierarchical structure shown in 1b, the ultra-thin single-crystal porous ZnO nanosheets are about 4 µm in length, 500 nm in width, and 12 nm in thickness, and the nanoholes are evenly distributed throughout the nanosheet.

[0058] (2) Modification of ZnO m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com