Method for gasifying CO2 and recycling emptied material in dimethyl carbonate production

A technology of dimethyl carbonate and CO2, which is applied in the direction of chemical instruments and methods, separation methods, carbon dioxide or inorganic carbonate preparation, etc., can solve the problems of high production cost, high investment cost, poor cooling effect, etc., and achieve good economy Benefits and social benefits, reduce investment costs, and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

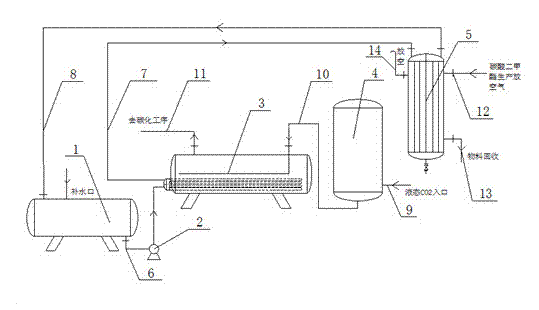

[0025] Take the production plant with an annual output of 40,000 tons of dimethyl carbonate as an example: a water storage tank (10m 3 ) and a circulating water pump (flow Q=30m 3 / h; head H=40m), circulating water (water temperature 28°C) passes through CO 2 vaporizer 3, with liquid CO 2 (-17°C) for heat exchange, its own temperature is reduced (water temperature is 0°C), and the circulating water pump is injected into the vent condenser 5 to perform heat exchange with dimethyl carbonate venting air (temperature is 50°C), and the vent condenser The gaseous material in the gas phase is condensed into a liquid (at a temperature of 35° C.) for recovery, and the water itself is heated (at 30° C.) and then returned to the water storage tank 1, thus forming a closed loop with water as the heat transfer medium. Liquid CO 2 After heat exchange with circulating water, it changes from liquid state to gaseous state (temperature is -2°C), the pressure is within 1.0MPa, and the flow ra...

example 2

[0027] Take the production plant with an annual output of 40,000 tons of dimethyl carbonate as an example: a water storage tank (15m 3 ) and a circulating water pump (for example: flow Q=20m 3 / h; Head H=60m), the circulating water (water temperature is 35°C) passes through CO 2 vaporizer 3, with liquid CO 2 (-15°C) for heat exchange, its own temperature is reduced (water temperature is 5°C), and the circulating water pump is pumped into the vent condenser 5 to perform heat exchange with dimethyl carbonate venting air (temperature is 60°C), and the vent condenser The gaseous material in the gas phase is condensed into a liquid (temperature is 25° C.) and recovered, and the water itself is heated (25° C.) and then returned to the water storage tank 1, thus forming a closed loop with water as the heat transfer medium. Liquid CO 2 After heat exchange with circulating water, it changes from liquid state to gaseous state (temperature is -5°C), the pressure is within 1.0MPa, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com