Swill-cooked dirty oil sulfonate as well as preparation method and application thereof

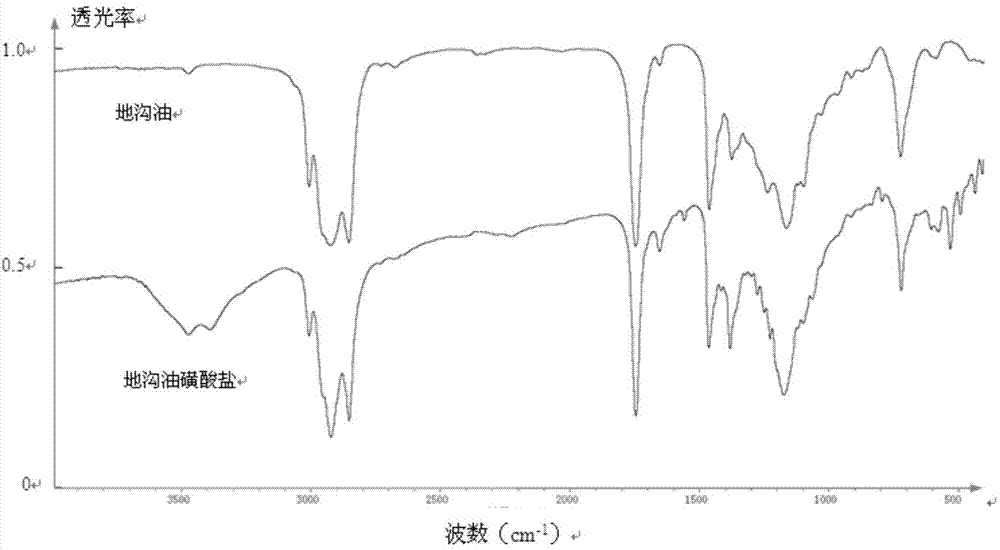

A technology of oil sulfonate and waste oil, which is applied in the directions of sulfonate preparation, chemical instruments and methods, drilling composition, etc., can solve the difficulty of direct utilization of waste oil, strong corrosiveness of fuming concentrated sulfuric acid, and difficulty in popularization. application and other issues, to achieve the effects of excellent surface/interfacial tension, lower tertiary oil recovery costs, and easy scale-up operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

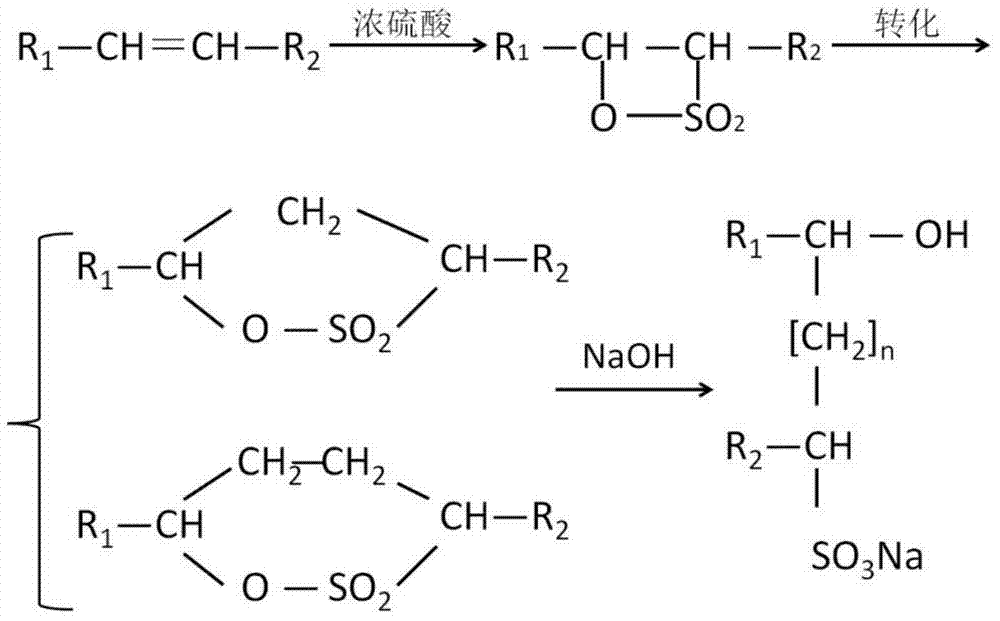

Method used

Image

Examples

Embodiment 1

[0023] In a three-necked beaker, slowly add an aqueous solution of 100g of sodium dodecylbenzenesulfonate (1wt%) into 100g of waste oil (without purification treatment), sodium dodecylbenzenesulfonate is used as a hydrolyzed emulsifier, and the stirring rod is put down , at a temperature of 60-80°C, at a speed of 500r / min, stir for 30-50min, so that the waste oil can be evenly dispersed, and the color of the system in the beaker is light yellow; slowly drop 5g of concentrated sulfuric acid as a sulfonating agent, Control the reaction temperature to 70-80°C and stir at a speed of 500r / min. Take the first drop of concentrated sulfuric acid as the timing starting point, finish dropping the concentrated sulfuric acid within 15 to 25 minutes, then raise the temperature to 80 to 90°C, after 5 to 8 minutes, the reaction is over, and the color of the system in the beaker is black; Reduce the rotational speed to 100 r / min, and slowly add NaOH aqueous solution with a prepared mass conce...

Embodiment 2

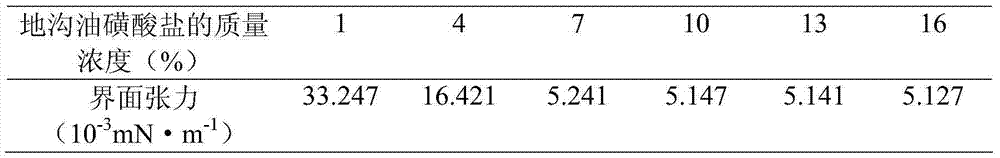

[0029] In order to evaluate the performance of reducing interfacial tension of waste oil sulfonate of the present invention, the following experiments were carried out. The waste oil sulfonate that obtains in embodiment 1 is formulated into the aqueous solution that mass fraction is respectively 1%, 4%, 7%, 10%, 13%, 16% series concentration, and adds Xinjiang petroleum sulfonate ( KPS), so that its mass fraction is 0.1%. Adopt dataphysics spinning drop interfacial tensiometer to measure Xinjiang crude oil (crude oil density: 0.9204g / cm2) 3 ) and formation water, where the temperature is 25°C. The obtained results are shown in Table 1:

[0030] Table I

[0031]

[0032] In Table 1, Xinjiang petroleum sulfonate was added to the prepared waste oil sulfonate aqueous solution so that the mass fraction was 0.1%.

[0033] Among them, Xinjiang Petroleum Sulfonate (KPS) is a commonly used tertiary oil recovery surfactant, produced by Karamay Petrochemical Company, and its main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com