Preparation method of hyaluronic acid-chitosan degradable dressing

A technology of hyaluronic acid and chitosan, which is applied in medical science, absorbent pads, bandages, etc., can solve the problems of no antibacterial activity, limited application range, no ability to treat and repair wounds, etc., and achieve the purpose of diluting and eliminating scars, The process is simple and the effect of preventing scar hyperplasia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

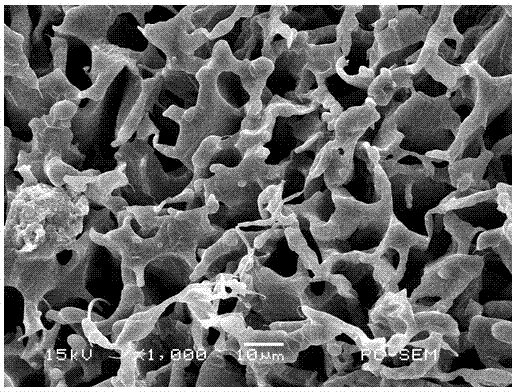

Image

Examples

Embodiment 1

[0024] (1) Preparation of hyaluronic acid solution: the molecular weight Mw=1×10 6 g / mol hyaluronic acid is directly dissolved in deionized water, the mass concentration of hyaluronic acid is 0.5%, and then sodium chloride solid with a mass fraction of 0.5% is added to the hyaluronic acid aqueous solution, and magnetically stirred to dissolve;

[0025] (2) Preparation of chitosan solution: set molecular weight Mw=1×10 5 g / mol chitosan is dissolved in 1% dilute hydrochloric acid solution by mass fraction, stirred and dissolved to obtain a chitosan solution with a concentration of 5%;

[0026] (3) Cross-linking reaction: Mix the hyaluronic acid solution and chitosan solution at a mass ratio of 9:1, stir and mix evenly at room temperature, and add glutaraldehyde with a mass concentration of 0.1% into the solution as a cross-linking agent , stirred and reacted at temperature T=40°C for 8 hours, and the solution became a gel state;

[0027] (4) Dry molding: add fine pearl powde...

Embodiment 2

[0029] (1) Preparation of hyaluronic acid solution: the molecular weight Mw=1×10 6 g / mol hyaluronic acid is directly dissolved in deionized water, the mass concentration of hyaluronic acid is 0.5%, and then sodium chloride solid with a mass fraction of 0.5% is added to the hyaluronic acid aqueous solution, and magnetically stirred to dissolve;

[0030] (2) Preparation of chitosan solution: set molecular weight Mw=1×10 5 g / mol chitosan is dissolved in 1% dilute hydrochloric acid solution by mass fraction, stirred and dissolved to obtain a chitosan solution with a concentration of 5%;

[0031] (3) Cross-linking reaction: Mix the hyaluronic acid solution and chitosan solution at a mass ratio of 8:2, stir and mix evenly at room temperature, and add genipin with a mass concentration of 0.1% to the solution as a cross-linking agent , stirred and reacted at temperature T=40°C for 8 hours, and the solution became a gel state;

[0032] (4) Dry molding: add fine pearl powder and sal...

Embodiment 3

[0034] (1) Preparation of hyaluronic acid solution: the molecular weight Mw=1.5×106 g / mol hyaluronic acid is directly dissolved in deionized water, the mass concentration of hyaluronic acid is 1%, and then sodium chloride solid with a mass fraction of 0.5% is added to the hyaluronic acid aqueous solution, and magnetically stirred to dissolve;

[0035] (2) Preparation of chitosan solution: set molecular weight Mw=1×10 5 g / mol chitosan is dissolved in 1% dilute hydrochloric acid solution by mass fraction, stirred and dissolved to obtain a chitosan solution with a concentration of 5%;

[0036] (3) Cross-linking reaction: Mix the hyaluronic acid solution and chitosan solution at a mass ratio of 8:2, stir and mix evenly at room temperature, and add genipin with a mass concentration of 0.1% to the solution as a cross-linking agent , stirred and reacted at temperature T=60°C for 8 hours, and the solution became a gel state;

[0037] (4) Dry molding: add fine pearl powder and salvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com