Faint-scent and environment-friendly wood-plastic plate

A wood-plastic board, an environmentally friendly technology, applied in the field of wood-plastic board, to achieve the effects of easy recycling, good flexibility, water repellency and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

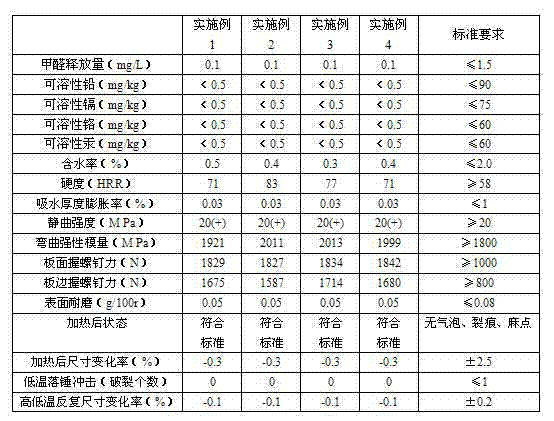

Embodiment 1

[0024] Step 1: Weigh the following components by weight in proportion: 30 parts by weight of PVC resin, 60 parts by weight of wormwood powder, 10 parts by weight of lavender powder, 5 parts by weight of calcium carbonate, 2 parts by weight of calcium zinc stabilizer, foaming 1 part by weight of agent, 4 parts by weight of chlorinated polyethylene, 0.6 part by weight of lubricant and 6.1 parts by weight of processing aid. Wherein the chemical name of AC foaming agent is that azodicarbonamide is purchased from Jinan Huaerwo Import and Export Trading Co., Ltd.; the lubricant is stearic acid, which is purchased from Permele B1801 produced by Kuala Lumpur Kepong Group Company, and the processing aid is Acrylate polymer was purchased from PVC processing aid HL-80 produced by Shandong Rike Chemical Co., Ltd.

[0025] Step 2: Mix 60 parts by weight of wormwood powder and 10 parts by weight of lavender powder evenly and then mix them with 15 parts by weight of PVC resin raw material, s...

Embodiment 2

[0029] Step 1: Weigh the following components by weight in proportion: 40 parts by weight of PVC resin, 25 parts by weight of wormwood powder, 15 parts by weight of lavender powder, 8 parts by weight of calcium carbonate, 1.8 parts by weight of calcium zinc stabilizer, foaming 0.6 parts by weight of agent, 2 parts by weight of chlorinated polyethylene, 0.3 parts by weight of lubricant and 5.2 parts by weight of processing aid. Wherein the chemical name of AC foaming agent is that azodicarbonamide is purchased from Jinan Huaerwo Import and Export Trading Co., Ltd.; the lubricant is stearic acid, which is purchased from Permele B1801 produced by Kuala Lumpur Kepong Group Company, and the processing aid is Acrylate polymer was purchased from PVC processing aid HL-80 produced by Shandong Rike Chemical Co., Ltd.

[0030] Step 2: Mix 25 parts by weight of wormwood powder and 15 parts by weight of lavender powder evenly, then mix with 20 parts by weight of PVC resin raw material, sti...

Embodiment 3

[0035]Step 1: Weigh the following components by weight in proportion: 50 parts by weight of PVC resin, 50 parts by weight of wormwood powder, 20 parts by weight of lavender powder, 10 parts by weight of calcium carbonate, 4 parts by weight of calcium zinc stabilizer, foaming 2 parts by weight of agent, 8 parts by weight of chlorinated polyethylene, 0.9 parts by weight of lubricant and 7.0 parts by weight of processing aid. Wherein the chemical name of AC foaming agent is that azodicarbonamide is purchased from Jinan Huaerwo Import and Export Trading Co., Ltd.; the lubricant is stearic acid, which is purchased from Permele B1801 produced by Kuala Lumpur Kepong Group Company, and the processing aid is Acrylate polymer was purchased from PVC processing aid HL-80 produced by Shandong Rike Chemical Co., Ltd.

[0036] Step 2: Mix 50 parts by weight of wormwood powder and 20 parts by weight of lavender powder evenly and then mix them with 25 parts by weight of PVC resin raw material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending failure load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com