Low-temperature 3PE hot melt adhesive and preparation method thereof

A hot-melt adhesive and low-temperature technology, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve problems such as poor adhesion and sealing, low strength, and high brittleness. Achieve excellent adhesion and sealing, low surface treatment requirements, good low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A low-temperature 3PE hot melt adhesive, which is composed of the following components by weight percentage:

[0025] EVA 10%

[0026] IIR 10%

[0027] EMH 35%

[0028] EPDM 15%

[0029] Polyisobutylene 5%

[0030] Terpene resin 10%

[0031] Rosin pentaerythritol ester 10%

[0032] Light calcium carbonate 4.5%

[0033] Antioxidant 0.5%

[0034] Wherein the melt index of EVA is 150g / 10min, and wherein by weight percentage, vinyl acetate content 28%;

[0035] IIR weight average molecular weight is 30×10 4 ;

[0036] The melt index of EMH is 50 g / 10min, and wherein by weight percentage, maleic anhydride content is 3%;

[0037] The Mooney viscosity of EPDM is 25 at ML125℃1+4;

[0038] The viscosity-average molecular weight of polyisobutylene is 100,000;

[0039] The softening point of terpene resin is 110°C;

[0040] The softening point of rosin pentaerythritol ester is 105°C;

[0041] The antioxidant is pentaerythritol tetrakis(β-(3,5-di-tert-butyl-4-hydroxyp...

Embodiment 2~6

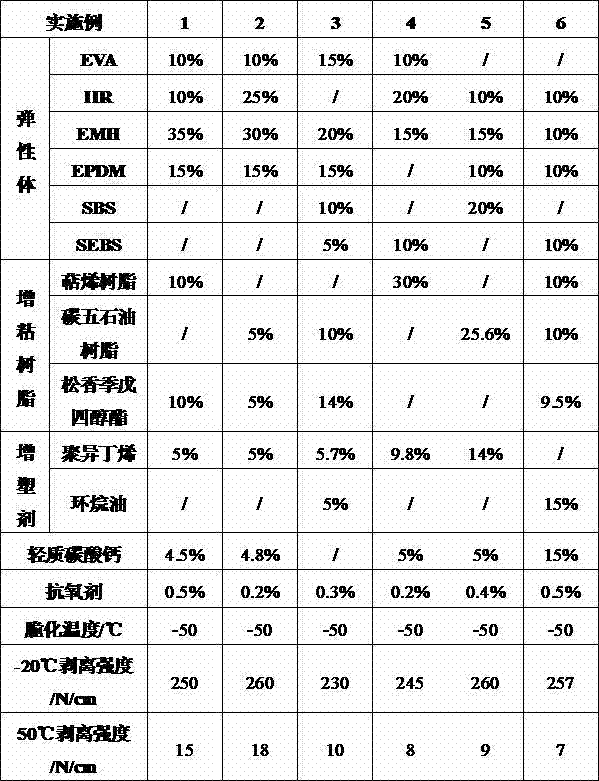

[0045] They are respectively a kind of 3PE hot-melt adhesive, and its components and dosage are shown in Table 1, and the rest including the preparation and use methods are the same as in Example 1.

[0046] Table 1

[0047]

[0048] The hot melt adhesive composition of each embodiment in Table 1 is calculated by weight percentage.

[0049] In Examples 2-6, the melt index of SBS is 2g / 10min. SEBS melt index is 2.5g / 10min. The softening point of C5 petroleum resin is 100°C.

[0050] It can be seen from Table 1 that the embrittlement temperature of the hot melt adhesives in Examples 1-6 all reaches -50°C, and the peel strength is relatively high in low temperature and high temperature environments, and the performance is stable. cm, good adhesion and sealing performance; 50 ℃, 15N / cm for primer steel, and the other two cases are cohesive and broken when peeled off, which can play a very good role in protecting the pipeline and has excellent anti-corrosion effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com