Heat barrier material high temperature heat conductivity plane heat source test system and method

A technology of planar heat sources and heat insulation materials, which is applied in the direction of material thermal development, etc., can solve the problems that the time delay of thermal signals is difficult to describe quantitatively, the heat capacity and thermal resistance of coatings cannot be ignored, and the use temperature is limited, etc., to achieve high temperature Thermal conductivity test, elimination of leakage voltage interference, good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

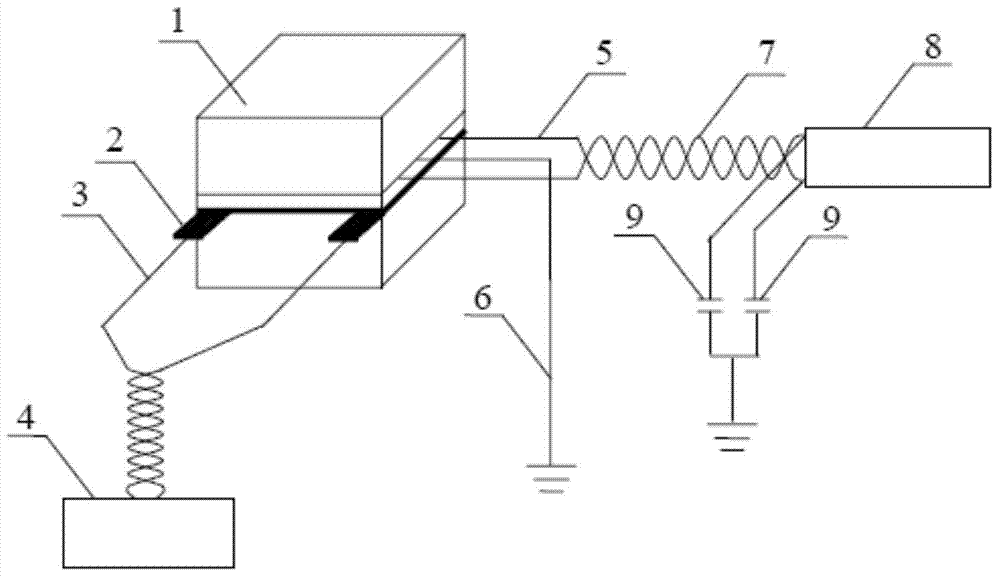

[0023] Such as figure 1 As shown, a plane heat source testing system for high-temperature thermal conductivity of a heat insulating material according to the present invention is characterized in that it includes three stacked samples 1 to be tested; the thickness of the middle sample is 3 to 15 mm (for example: 3mm, 9mm or 15mm), the thickness of the upper sample and the lower sample is 30-40mm (for example: 30mm, 35mm or 40mm).

[0024] The plane heat source 2 that provides constant power output is set between the middle sample and the lower sample, and the plane heat source is connected to the constant current source meter 4 through a high temperature resistant wire 3; the temperature measuring thermocouple 5 for testing the temperature response is set between the upper sample and the lower sample. Between the middle samples, the temperature measuring thermocouple 5 is connected to the temperature display instrument 8 through the compensation wire 7 .

[0025] The temperat...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of planar heat source test method of heat insulation material high temperature thermal conductivity described in the present invention, it comprises the following steps:

[0030] (a) Place three samples 1 to be tested in a high-temperature furnace, wherein the thickness of the upper sample and the lower sample is 30-40mm (for example: 30mm, 35mm or 40mm), and the thickness of the middle sample is 3-15mm (for example: 3mm , 9mm or 15mm);

[0031] Then place the plane heat source 2 that provides constant power output between the middle sample and the lower sample, and connect the plane heat source to the constant current source meter 4 through a high temperature resistant wire 3; set the temperature measuring thermocouple 5 for testing the temperature response on the upper part Between the sample and the middle sample, the temperature measuring thermocouple is connected to the temperature display instrument 8 through the compensation wire 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com