Structural microcrack vibration sound modulation detection system and structural microcrack vibration sound modulation detection method based on nonlinear vibrator

A vibration-acoustic modulation and detection system technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as inability to choose freely, affect detection results, and dependence on low-frequency resonance frequencies, and achieve high-efficiency detection and strong anti-interference , universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

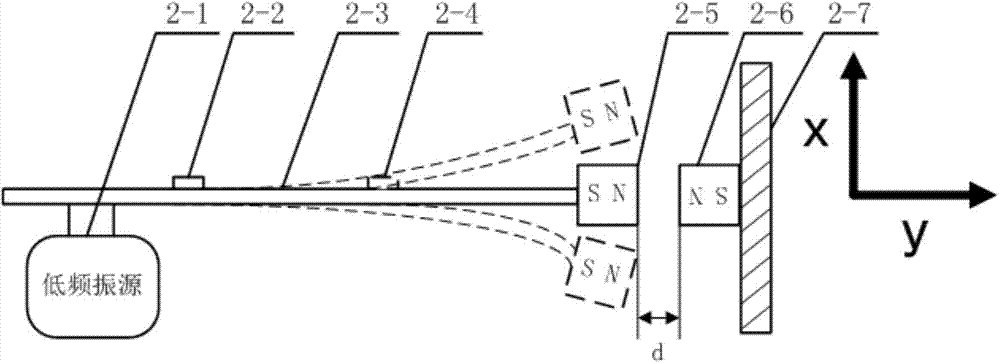

[0043] The nonlinear oscillator system described in this embodiment is as figure 2 As shown, it includes low-frequency vibration source 2-1, piezoelectric ceramic sheets 2-2 and 2-4, structure with cracks 2-3, permanent magnets 2-5 and 2-6, and base 2-7. in,

[0044] The low-frequency vibration source is low-frequency simple harmonic vibration simulated by a vibration table.

[0045] The material of the structure with cracks is phosphor copper, and the dimensions are 148mm×40mm×0.6mm (length×width×thickness), respectively, and a fatigue crack with a length of 5.8mm is produced by the fatigue test method.

[0046] The magnet system is composed of a permanent magnet 2-6;

[0047] The permanent magnet adopts NdFeB permanent magnet, the shape of the magnet is rectangular, the size is 5mm×5mm×2mm, and the magnet strength is 0.35 Tesla.

[0048] The polarities of the permanent magnets 2-5 and 2-6 are opposite in the y direction, and by adjusting the base 2-7, the right surface o...

Embodiment 2

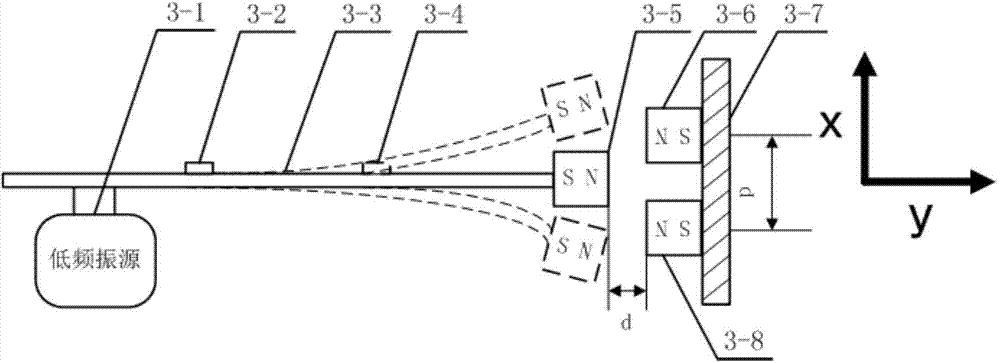

[0056] The nonlinear oscillator system described in this embodiment is as Figure 4 As shown, it includes a low-frequency vibration source 3-1, piezoelectric ceramic sheets 3-2 and 3-4, a structure with cracks 3-3, permanent magnets 3-5, 3-6 and 3-8, and a base 3-7. in,

[0057] The low-frequency vibration source is low-frequency simple harmonic vibration simulated by a vibration table.

[0058] The material of the structure with cracks is phosphor copper, and the dimensions are 153mm×40mm×0.6mm (length×width×thickness), respectively, and fatigue cracks with a length of 6mm are produced by the fatigue test method.

[0059] Described magnet system is made of two identical permanent magnets 3-6 and 3-8, and two magnets are placed in parallel along the x direction, and the distance between magnet centers is p, which is set to 6.2mm in this embodiment;

[0060] The permanent magnet adopts NdFeB permanent magnet, the shape of the magnet is rectangular, the size is 5mm×5mm×2mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com