Nanometer fusion lamination modified lithium ion battery positive electrode material and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems that the ideal coating effect cannot be achieved, the ionic conductivity of the coating layer is not improved much, and the performance improvement of the positive electrode material is limited. Achieve good chemical stability, improve electrochemical performance, and improve the effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Composition of nano-melt composite coating modified lithium-ion battery cathode material:

[0036] Positive electrode active material matrix: LiCoO 2 , content 99 wt%, nano oxide: La 2 o 3 (particle size 50nm), content 0.2 wt%, Li 2 TiO 3 , content 0.8 wt%.

[0037] Preparation:

[0038] (1) Dissolve 3.06 mL tetraethyl titanate (0.0145 mol) in 90 mL absolute ethanol, stir and add glacial acetic acid to pH=6 to obtain a uniform colloidal solution;

[0039] (2) Add 1.5 mL of n-butylamine to the colloidal solution obtained in step (1), then add 1.93 g of anhydrous lithium acetate (0.029 mol), and stir to obtain a solution containing 1.6 g of Li 2 TiO 3 coating solution;

[0040] (3) Slowly add 0.4 g of nano-oxide La to the coating solution obtained in step (2) 2 o 3 and 198 g of cathode material LiCoO 2 , and added 100 g of ethanol, heated and stirred at 60 °C, when the solution lost fluidity, a sol was obtained;

[0041] (4) Dry the sol obtained in step (3...

Embodiment 2

[0045] Composition of nano-melt composite coating modified lithium-ion battery cathode material:

[0046] Positive active material matrix: Li(Mn 1 / 3 Ni 1 / 3 co 1 / 3 )O 2 , content 98.5 wt%, nano oxide: MgO (particle size 30nm), content 0.3 wt%, Li 2 TiO 3 , content 1.2 wt%.

[0047] Preparation:

[0048] (1) Dissolve 6.5 mL of titanium isopropoxide (0.0219mol) in 180 mL of absolute ethanol, stir and add glacial acetic acid to pH=5.5 to obtain a uniform colloidal solution;

[0049] (2) Add 3 mL of hexamethylenediamine to the colloidal solution obtained in step (1), then add 2.89 g of anhydrous lithium acetate (0.0438 mol) and stir to obtain a solution containing 2.4 g of Li 2 TiO 3 coating solution;

[0050] (3) Slowly add 0.6 g of nano-oxide MgO and 197 g of cathode material Li(Mn 1 / 3 Ni 1 / 3 co 1 / 3 )O 2 , heating and stirring at 70 °C, when the solution loses fluidity, a sol is obtained;

[0051] (4) Dry the sol obtained in step (3) in an oven at 110 °C for 11 ...

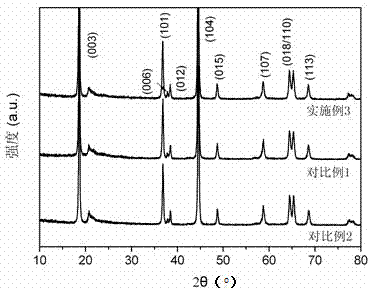

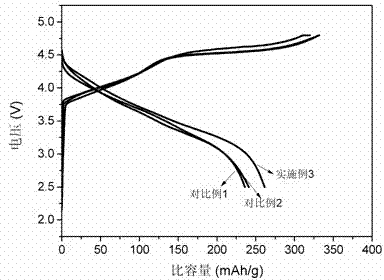

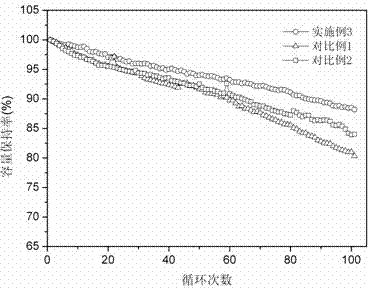

Embodiment 3

[0055] Composition of nano-melt composite coating modified lithium-ion battery cathode material:

[0056] Positive active material matrix: Li 1.2 (Mn 0.56 Ni 0.16 co 0.08 )O 2 (The expression can also be written as 0.6Li[Li 1 / 3 mn 2 / 3 ]O 2 0.4Li[Ni 0.4 mn 0.4 co 0.2 ]O 2 ), content 98 wt%, nano oxide: Al 2 o 3 (particle size 30 nm), content 0.4 wt%, Li 2 TiO 3 , content 1.6 wt%.

[0057] Preparation:

[0058] (1) Dissolve 10.3 mL tetrabutyl titanate (0.029 mol) in 257.5 mL absolute ethanol, stir and add glacial acetic acid to pH=5 to obtain a uniform colloidal solution;

[0059] (2) Add 5 mL of dodecylamine to the colloidal solution obtained in step (1), then add 3.85 g of anhydrous lithium acetate (0.058 mol), and stir to obtain a solution containing 3.2 g of Li 2 TiO 3 coating solution;

[0060] (3) Slowly add 0.8 g nano-oxide Al to the coating solution obtained in step (2) 2 o 3 and 196 g of cathode material Li 1.2 (Mn 0.56 Ni 0.16 co 0.08 )O 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com