Mesoporous carbon supported N-heterocyclic carbene-palladium catalyst as well as preparation and application thereof

A nitrogen heterocyclic carbene, palladium catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the loss of palladium and affect the reuse of supported catalysts performance and other issues, to achieve the effect of preventing loss, excellent reuse performance, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

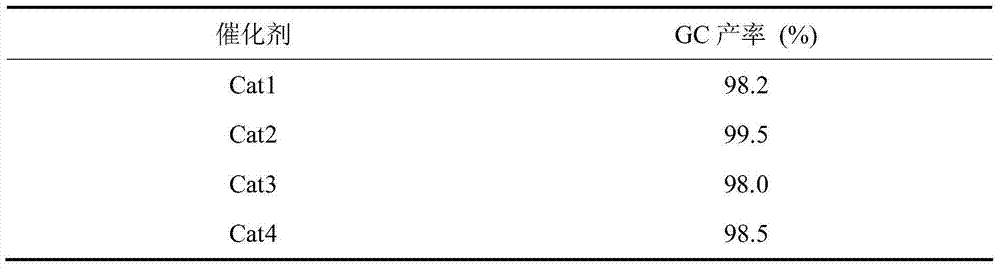

Examples

Embodiment 1

[0027] Add 2.0 g of SBA-15 into a mixed solution of 10 g of deionized water, 2.50 g of sucrose and 0.28 g of concentrated sulfuric acid, place the above mixture in an oven and heat it at 373K for 6 hours, then raise the temperature to 433K and heat it for 6 hours to obtain a brown solid; grind Then add a mixed solution of 10 g of deionized water, 1.60 g of sucrose and 0.18 g of concentrated sulfuric acid, and repeat the above heating steps. After the obtained product was carbonized at a constant temperature of 823K for 5 hours in an argon atmosphere, the cooled black powder was added to 100 g of HF solution (10% by mass) to remove the ordered mesoporous silicon template SBA-15, washed several times with distilled water and dried at 393K. The ordered mesoporous carbon material CMK–3 can be obtained. Add 2g of concentrated nitric acid (68% by mass) to the bottom of the polytetrafluoroethylene inner liner of a 100mL autoclave, place a polytetrafluoroethylene beaker containing 0.3...

Embodiment 2

[0030]Add 0.5 g of the hydroxylated mesoporous carbon to 100 g of toluene solution containing trimethoxychloropropane, wherein the mass percentage of the toluene solution of trimethoxychloropropane is 2.0%, ultrasonically vibrate for 120 min, and at a temperature of 80 The reaction was stirred at ℃ for 720 minutes, cooled to room temperature, and the product was centrifuged, washed with 10 g of ethanol and 10 g of distilled water in turn, and dried in vacuum to obtain a black powder, which is chloropropyl silicon mesoporous carbon. Add 0.4 g of the mesoporous carbon of chloropropyl silicon to 100 g of imidazole-containing toluene solution, wherein the mass percentage of imidazole in toluene solution is 5.0%, ultrasonically oscillate for 120 min, and stir the reaction at a temperature of 80 ° C After cooling to room temperature for 720 min, the product was centrifuged and washed successively with 10 g of ethanol and 10 g of distilled water until the eluent was neutral; after fre...

Embodiment 3

[0032] Add 0.5 g of the hydroxylated mesoporous carbon to 100 g of toluene solution containing trimethoxychloropropane, wherein the mass percentage of the toluene solution of trimethoxychloropropane is 2.0%, ultrasonically vibrate for 120 min, and at a temperature of 80 The reaction was stirred at ℃ for 720 minutes, cooled to room temperature, and the product was centrifuged, washed with 10 g of ethanol and 10 g of distilled water in turn, and dried in vacuum to obtain a black powder, which is chloropropyl silicon mesoporous carbon. Add 0.4g of the mesoporous carbon of chloropropyl silicon to 100g of toluene solution containing 1-methylimidazole, wherein the mass percentage of the toluene solution of 1-methylimidazole is 5.0%, ultrasonically vibrate for 120min, at temperature Stir and react at 80°C for 720min, cool to room temperature, and centrifuge the product, then wash with 10g of ethanol and 10g of distilled water until the eluent is neutral; after freeze-drying, the black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com