Catalyst used for catalytic rectification selective hydrogenation, preparation method and application thereof

A technology of selective hydrogenation and catalytic rectification, applied in the directions of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The mechanical strength and wear resistance of the catalyst carrier are poor, and the effect of increasing the gas-liquid exchange area, good activity and good liquid distribution can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

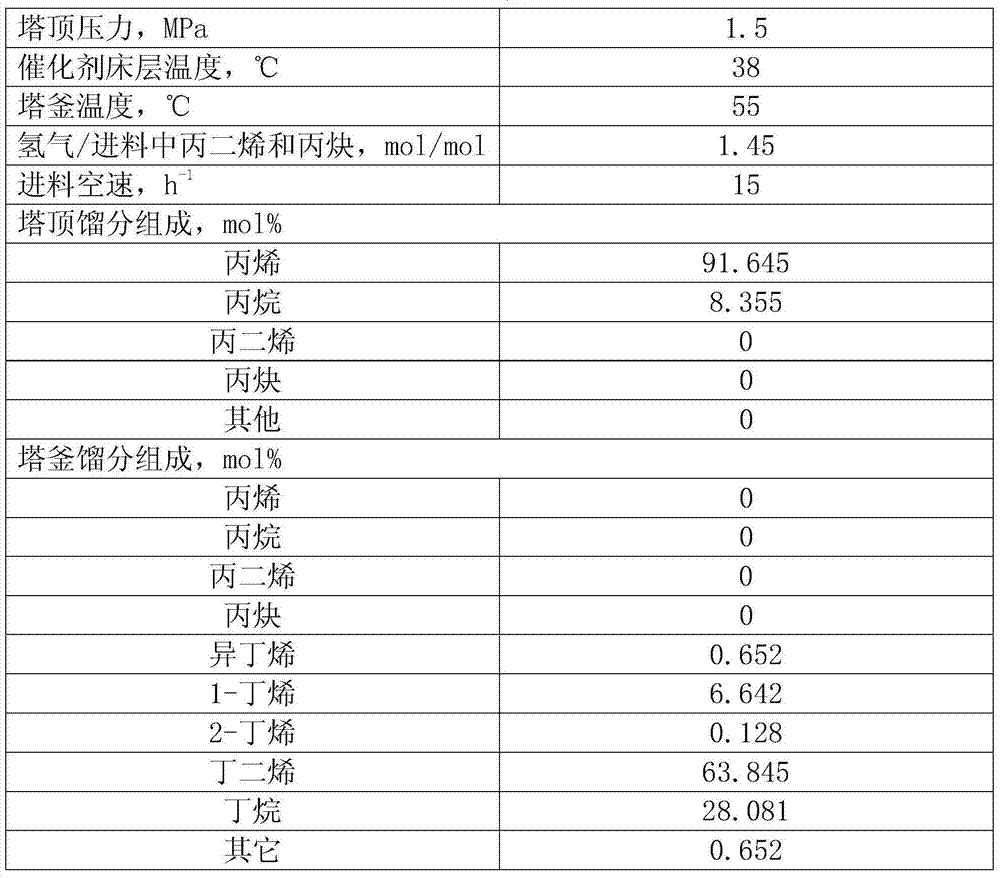

Embodiment 1

[0041] (1) Prepare Pd(NO 3 ) 2 Solution, using the equal volume impregnation method, put 3-5mm alumina pellets in Pd(NO 3 ) 2 After dipping in the solution, it was dried at 120°C for 4 hours, then calcined at 500°C for 2 hours, and the Pd catalyst was obtained after reduction. The Pd catalyst is pulverized and sieved to obtain catalyst powder of 80-100 mesh.

[0042] (2) Take nylon-6 particles (Baling Petrochemical, BL2340-H) and place them in the above catalyst powder, mold them with a flat vulcanizer at a temperature of 250°C and a pressure of 7 MPa for 10 minutes, take them out and cool them, sieve them, and sieve them Spherical particles are produced, and the surface of the particles is completely covered by the palladium catalyst, that is, a supported catalyst is obtained, which we call catalyst A.

[0043] Put 10 liters of the catalyst prepared above into a metal corrugated wire mesh, and pack it on a packing frame in the middle of a catalytic distillation tower with...

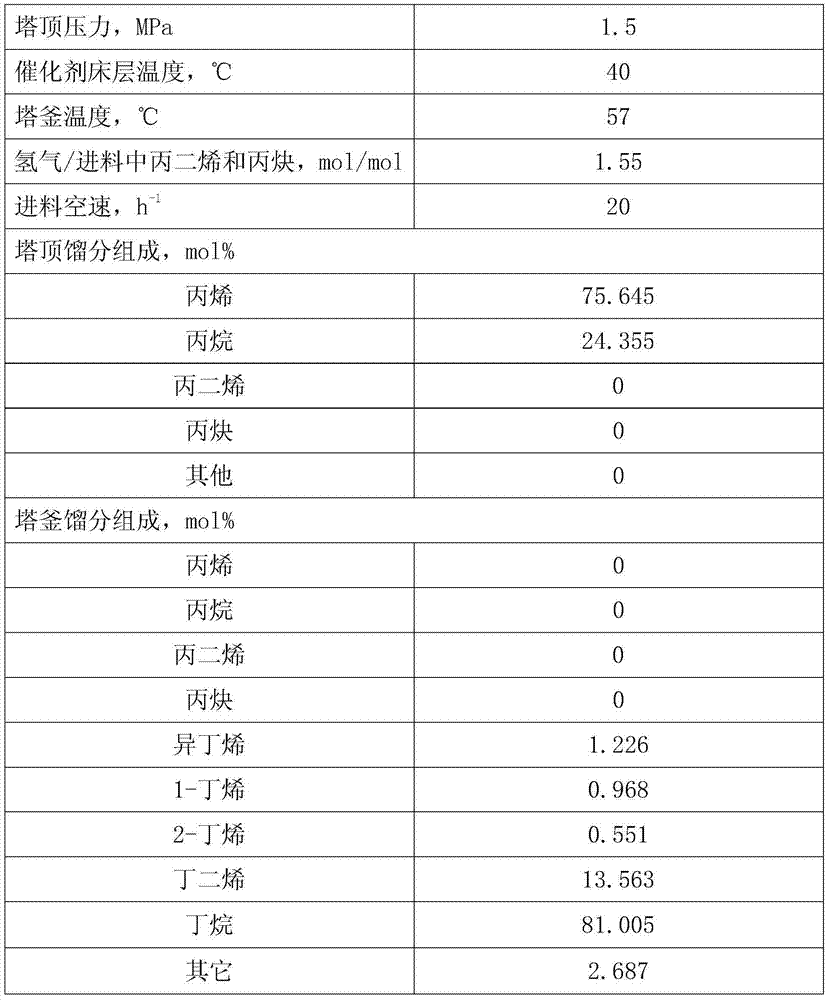

Embodiment 2

[0045] (1) Prepare Pt(NO 3 ) 2 Solution, using the equal volume impregnation method, the 3-5mm silica pellets in Pt(NO 3 ) 2 After dipping in the solution, it was dried at 120°C for 4 hours, and then baked at 500°C for 2 hours.

[0046] (2) Prepare 25mg / ml Zn(NO 3 ) 2 solution. The above catalyst was impregnated with Zn(NO 3 ) 2 After solution, dry at 120°C for 4 hours, then bake at 500°C for 2 hours, and obtain Pt-Zn / SiO after reduction 2 catalyst. It is pulverized and sieved, and 80-100 mesh catalyst powder is retained.

[0047] (3) Mold polypropylene powder (Maoming Petrochemical, F280M) with a flat vulcanizer at a temperature of 200 °C and a pressure of 7 MPa for 10 mins to form a sheet with a thickness of about 1 mm and a wavy shape. Lay a layer of Pt-Zn / SiO on the top and bottom of the polypropylene sheet 2 Put the catalyst powder into a flat vulcanizer, mold it for 10mins at a temperature of 200°C and a pressure of 7MPa, take it out and cool it, and the upper...

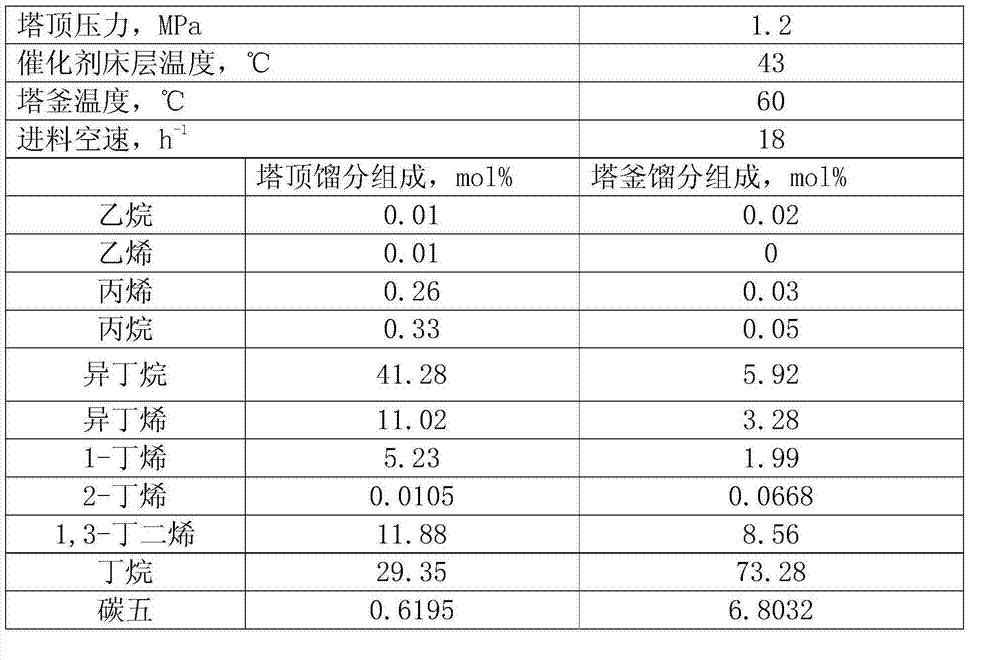

Embodiment 3

[0050] (1) Prepare Ni(NO 3 ) 2 Solution, using the excess impregnation method, the 3-5mm alumina pellets in Ni(NO 3 ) 2 Immerse in the solution, dry at 120°C for 4 hours, repeat several times until the loading of nickel nitrate reaches 60%, then bake at 500°C for 2 hours.

[0051] (2) Prepare 10mg / ml Mo(NO 3 ) 2 solution. The above catalyst was impregnated with Ni(NO 3 ) 2 After solution, it was dried at 120 °C for 4 hours, and then calcined at 500 °C for 2 hours, and Ni–Mo / Al was obtained after reduction. 2 o 3 catalyst. It is pulverized and sieved, and 80-100 mesh catalyst powder is retained.

[0052] (3) Extrude polypropylene powder (Maoming Petrochemical, F280M) into a ring-shaped plate with a thickness of 6 mm, an outer diameter of 5 mm, and an inner diameter of about 3 mm with a flat vulcanizer at a temperature of 200 ° C and a pressure of 7 MPa. – Mo / Al2O3 catalyst powder and polypropylene plate are mixed and placed in a flat vulcanizer, molded at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com