Joint preparation method of polysaccharide and protein peptide

A combined preparation and protein peptide technology, which is applied in the separation and extraction of proteins and polysaccharides, can solve the problems of low utilization rate of raw materials, low product yield, lack of joint preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for the joint preparation of polysaccharides and protein peptides, comprising the following steps:

[0030] (1) Raw material pretreatment: Take 1.5kg of frozen abalone viscera, grind it through a 1mm aperture meat grinder, and send it to the enzymatic hydrolysis tank as raw material, add 7.5kg of water to fully mix to make a feed liquid, and heat the feed liquid to 105°C After 15 minutes, cool down to 50°C.

[0031] (2) The first enzymolysis: adjust the pH of the feed solution to 10.0, the temperature is 52°C, add 600U / g of raw material neutral protease, enzymolyze at a constant temperature for 8 hours, boil for 15min, cool to 30°C, and the enzymolysis solution is at 5000rpm Centrifuge down to get the precipitate and enzymatic solution;

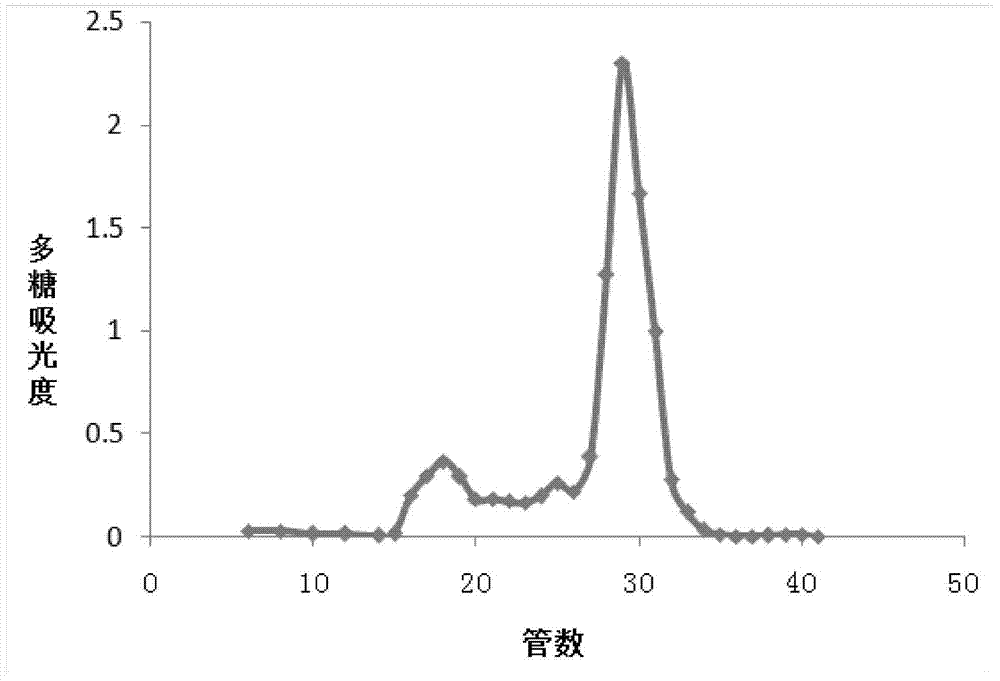

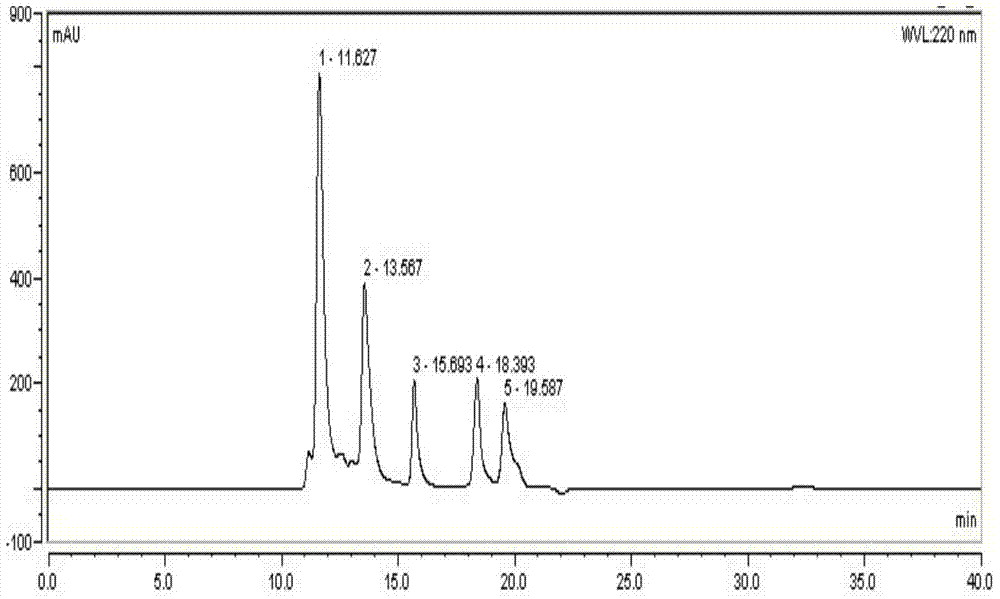

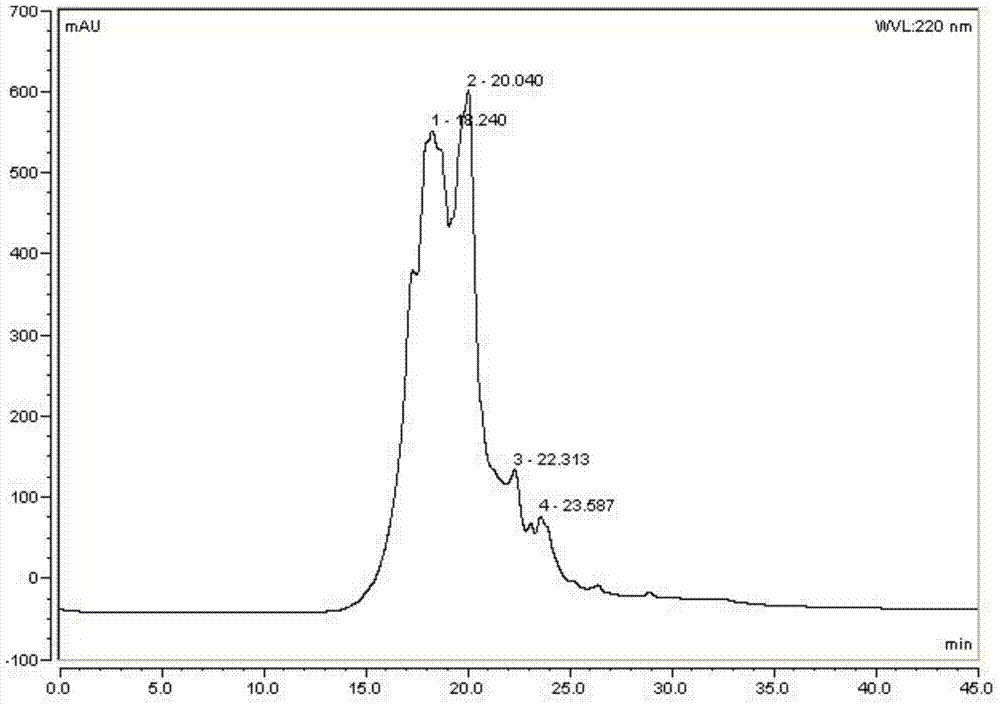

[0032] (3) Membrane separation for the first time: the enzymatic hydrolysis solution is separated by an ultrafiltration membrane with a molecular weight cut-off of 10000Da, and the ultrafiltration is stopped when the volume o...

Embodiment 2

[0037] A method for the joint preparation of polysaccharides and protein peptides, comprising the following steps:

[0038] (1) Raw material pretreatment: Take 1 kg of fresh abalone viscera, grind it through a 2mm aperture meat grinder, and send it into the enzymolysis tank as raw material, add 8 kg of water to fully mix to make a feed liquid, heat the feed liquid to 100°C for 10 minutes, and cool down to 50°C.

[0039] (2) The first enzymolysis: adjust the pH of the feed solution to 10.0, the temperature is 52°C, add 200U / g of raw material neutral protease, enzymolysis at constant temperature for 16hr, boil for 10min, cool to 30°C, and the enzymolysis solution is at 5000rpm Centrifuge down to get the precipitate and enzymatic solution;

[0040] (3) Membrane separation for the first time: the enzymolysis solution is separated by ultrafiltration with a molecular weight cut-off of 5000Da, and the ultrafiltration is stopped when the volume of the retentate is about 1500ml.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com