Magnetic iron oxide/sepiolite nanocomposite and preparation method and application thereof

A nano-composite material and magnetic iron oxide technology, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of high toxicity, and achieve simple operation, large capacity, and powerful physical The effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

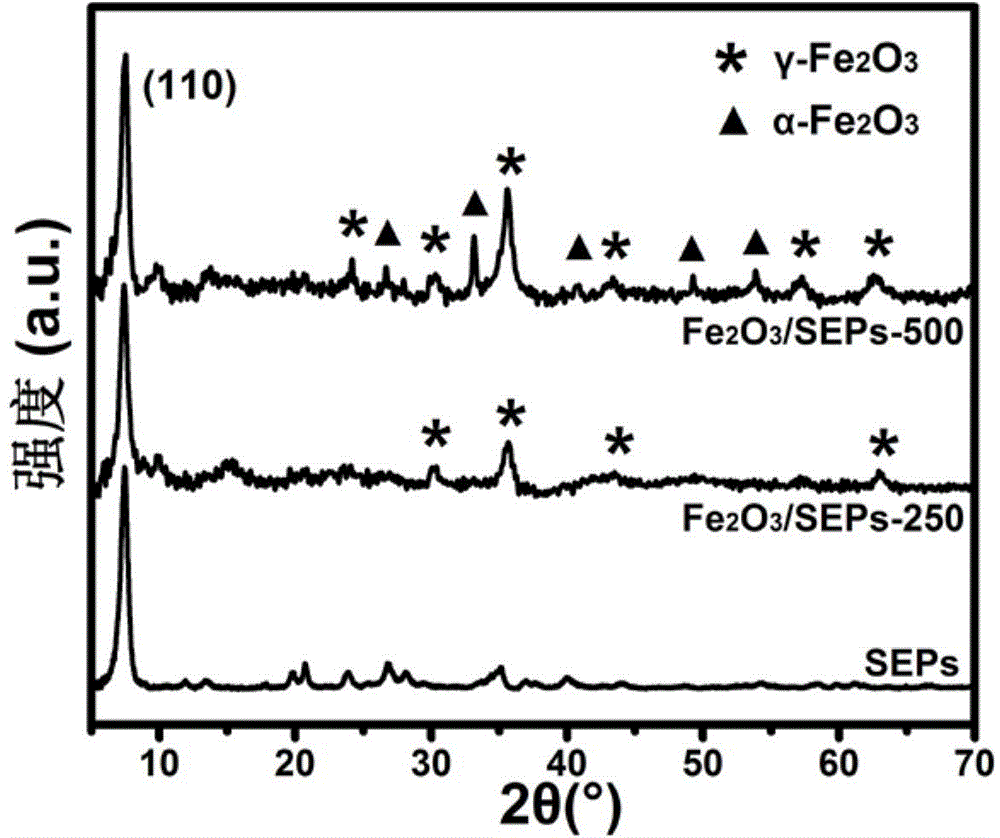

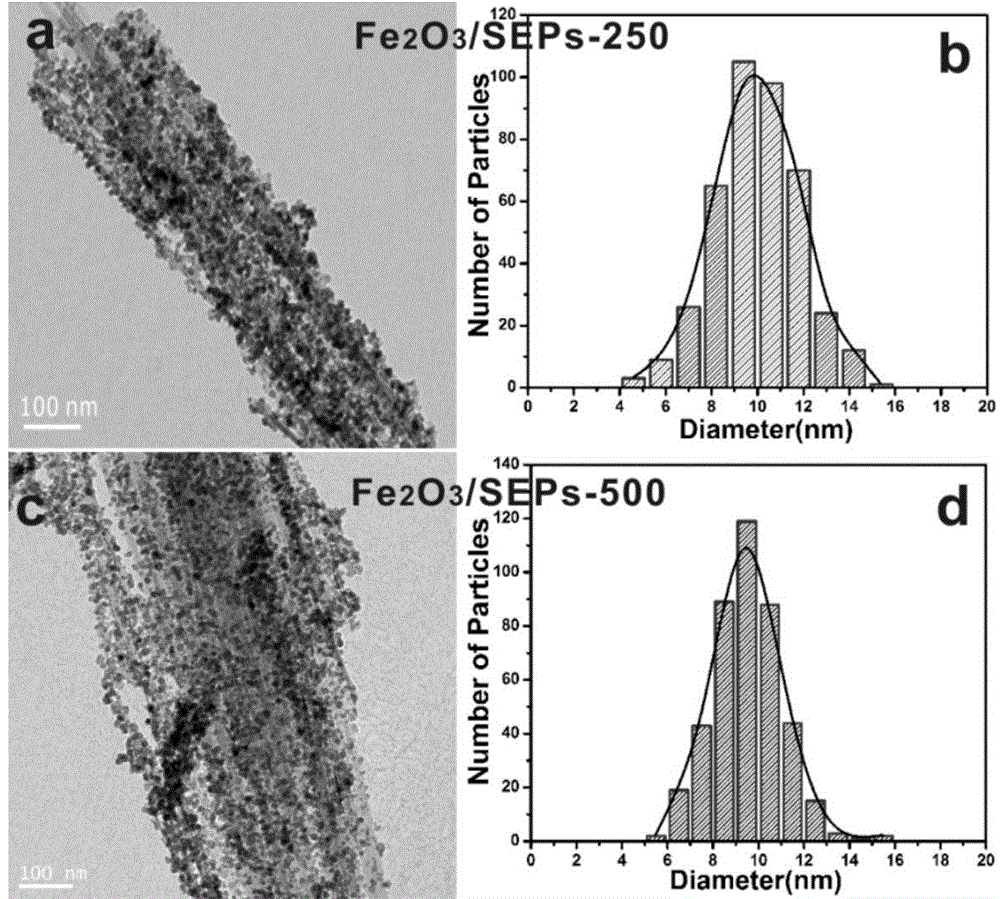

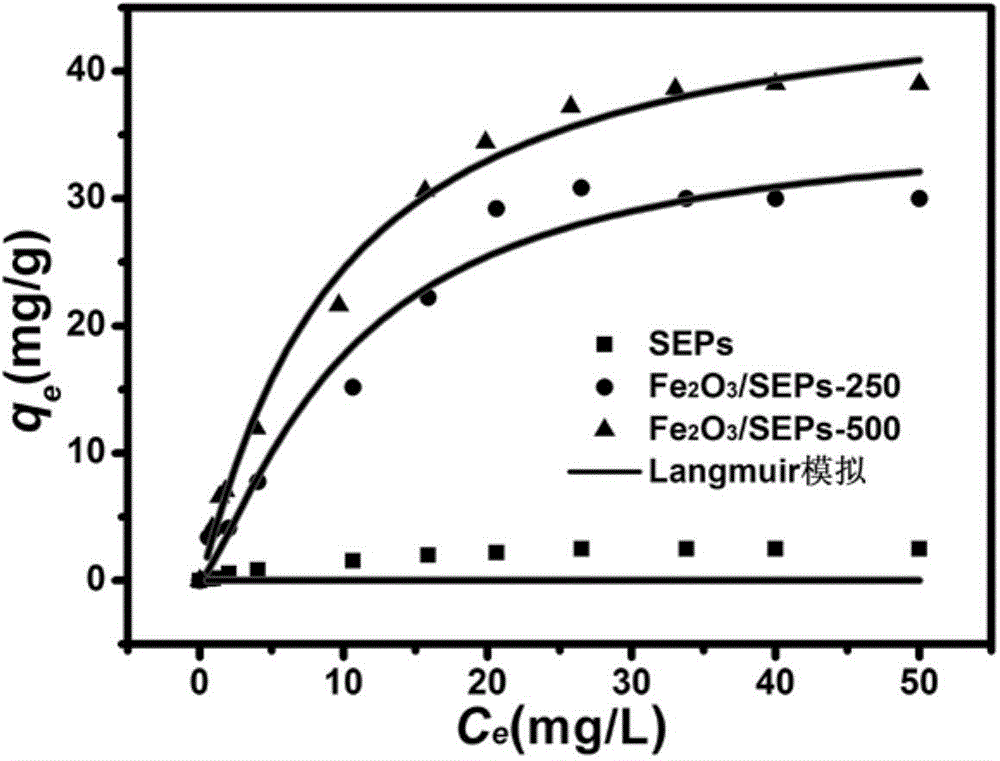

Embodiment 1

[0021] The preparation method of the magnetic iron oxide / sepiolite nanocomposite material prepared in this example is as follows: prepare a sepiolite solution with a concentration of 12.5g / L, add a certain amount of glucose, and make the mass ratio of sepiolite to glucose The ratio is 1:5; after stirring at 400rpm for 24 hours, put the mixed solution A into the reaction kettle for hydrothermal carbonization reaction at 160°C for 48h, and wash the brown substance formed by the reaction with deionized water and absolute ethanol, and heat it at 60°C After drying in an oven, sepiolite nanofibers with multifunctional active groups are obtained; sepiolite nanofibers and iron acetylacetonate are formulated into a certain concentration of mixed solution B at a mass ratio of 1:2, and the Stir for 12 hours, mix well and put it into the reaction kettle to carry out solvothermal reaction at 220°C for 12 hours. The solvent used in the solvothermal reaction is triethylene glycol solution. Th...

Embodiment 2

[0027]The preparation method of the magnetic iron oxide / sepiolite nanocomposite material prepared in this example is as follows: prepare a sepiolite solution with a concentration of 12.5g / L, add a certain amount of glucose, and make the mass ratio of sepiolite to glucose The ratio is 1:2; after stirring for 24 hours, put the mixed solution A into the reaction kettle for hydrothermal carbonization reaction at 160°C for 70h, and the brown substance produced by the reaction is washed with deionized water and absolute ethanol, and dried in an oven at 60°C to obtain Sepiolite nanofibers with multifunctional active groups; prepare sepiolite nanofibers and iron acetylacetonate at a mass ratio of 1:3 to form a mixed solution B of a certain concentration, mix them uniformly and put them into a reaction kettle at a temperature of 220°C Carry out solvothermal reaction for 7 hours, wash the generated material with deionized water, dry it in vacuum for 5 hours, grind the dried solid into po...

Embodiment 3

[0029] The preparation method of the magnetic iron oxide / sepiolite nanocomposite material prepared in this example is as follows: prepare a sepiolite solution with a concentration of 12.5g / L, add a certain amount of glucose, and make the mass ratio of sepiolite to glucose The ratio is 1:7.5; after stirring for 24 hours, put the mixed solution A into the reaction kettle for hydrothermal carbonization reaction at 160°C for 30 hours, wash the brown substance formed by the reaction with deionized water and absolute ethanol, and dry it in an oven at 60°C to obtain Sepiolite nanofibers with multifunctional active groups; prepare sepiolite nanofibers and iron acetylacetonate at a mass ratio of 1:4 to form a mixed solution B of a certain concentration, mix them evenly and put them into a reaction kettle at a temperature of 220°C Carry out solvothermal reaction for 22 hours, wash the generated material with deionized water, vacuum dry for 9 hours, grind the dried solid into powder, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com