Supported metal organic skeleton/graphene oxide hydrogen storage material and preparation method thereof

A technology of metal-organic frameworks and hydrogen storage materials, which is applied in chemical instruments and methods, hydrogen production, and other chemical processes. The effect of maturity, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 2.933 g of zinc nitrate and 4.867 g of 2-methylimidazole in 230 mL of methanol, then add 0.390 g of graphene oxide, and stir at 10° C. for 6 hours. The centrifuged product was washed three times with methanol (10 mL each time) to prepare the ZIF-8 / graphene oxide carrier material.

[0024] (2) Dissolve 8.38 mg of palladium chloride and 20.6 mg of polyvinyl alcohol in 42 mL of deionized water, and stir for 1 hour. Then add 200 mg of ZIF-8 / graphene oxide, stir for 2 hours, then slowly add 15 mg of sodium borohydride, and stir for 5 hours. The centrifuged product was washed twice with water (10 mL each time), and dried at 60° C. for 24 hours to obtain a supported metal organic framework / graphene oxide hydrogen storage material.

Embodiment 2

[0026] (1) Dissolve 2.933 g of zinc sulfate and 6.489 g of 2-methylimidazole in 280 mL of methanol, then add 0.471 g of graphene oxide, and stir at 30° C. for 4 hours. The centrifuged product was washed three times with methanol (10 mL each time) to prepare the ZIF-8 / graphene oxide carrier material.

[0027] (2) Dissolve 25.14 mg of tetrachloropalladium acid and 61.80 mg of polyvinyl alcohol in 126 mL of deionized water, and stir for 1 hour. Then add 200 mg of ZIF-8 / graphene oxide, stir for 2 hours, then slowly add 45 mg of potassium borohydride, and stir for 5 hours. The centrifuged product was washed twice with water (10 mL each time), and dried at 60° C. for 24 hours to obtain a supported metal organic framework / graphene oxide hydrogen storage material.

Embodiment 3

[0029] (1) Dissolve 2.933g of zinc chloride and 8.111g of 2-methylimidazole in 330mL of methanol, then add 0.552g of graphene oxide, and stir at 50°C for 2 hours. The centrifuged product was washed three times with methanol (10 mL each time) to prepare the ZIF-8 / graphene oxide carrier material.

[0030] (2) Dissolve 41.90 mg of palladium acetylacetonate and 103.00 mg of polyvinyl alcohol in 210 mL of deionized water, and stir for 1 hour. Then add 200 mg of ZIF-8 / graphene oxide, stir for 2 hours, then slowly add 75 mg of hydrazine hydrate, and stir for 5 hours. The centrifuged product was washed twice with water (10 mL each time), and dried at 60° C. for 24 hours to obtain a supported metal organic framework / graphene oxide hydrogen storage material.

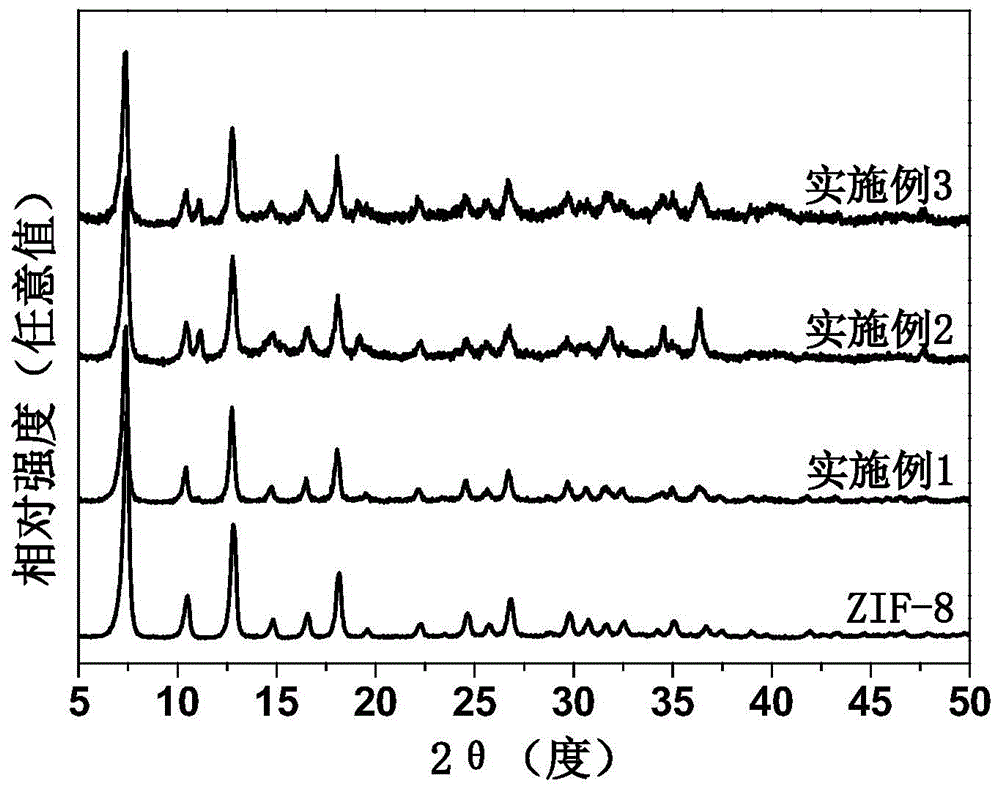

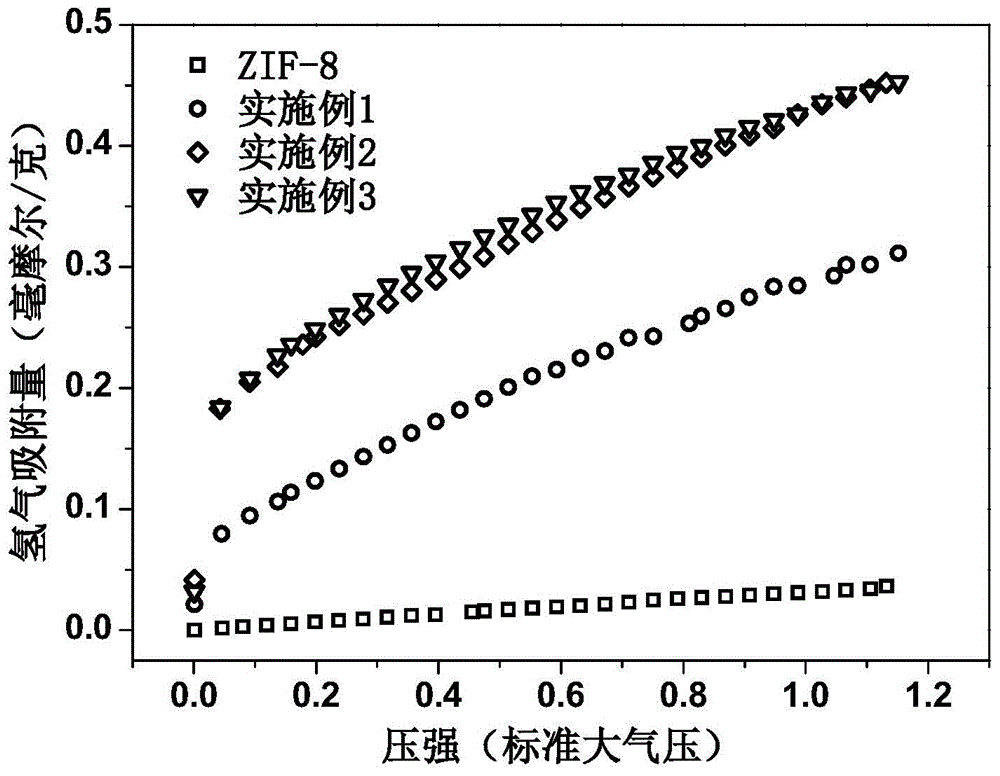

[0031] The room temperature hydrogen storage test of the hydrogen storage materials prepared in Examples 1-3 was completed on the ASAP 2020 device of American Mike Company, and the samples were vacuum degassed at 160° C. for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com