Preparation method of phosphotungstic acid and carbon nitride composite photocatalyst

A carbon nitride, phosphotungstic acid technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of difficult recovery and limited industrial application, etc. Achieve the effects of easy recovery, improved photocatalytic efficiency and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

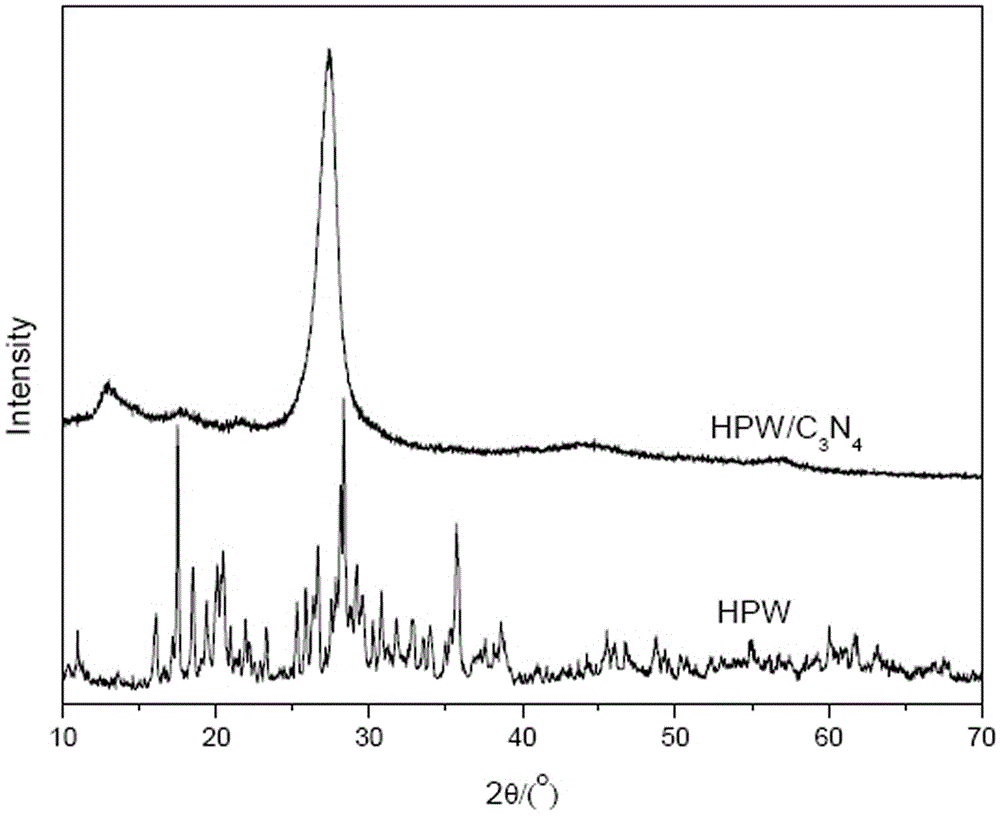

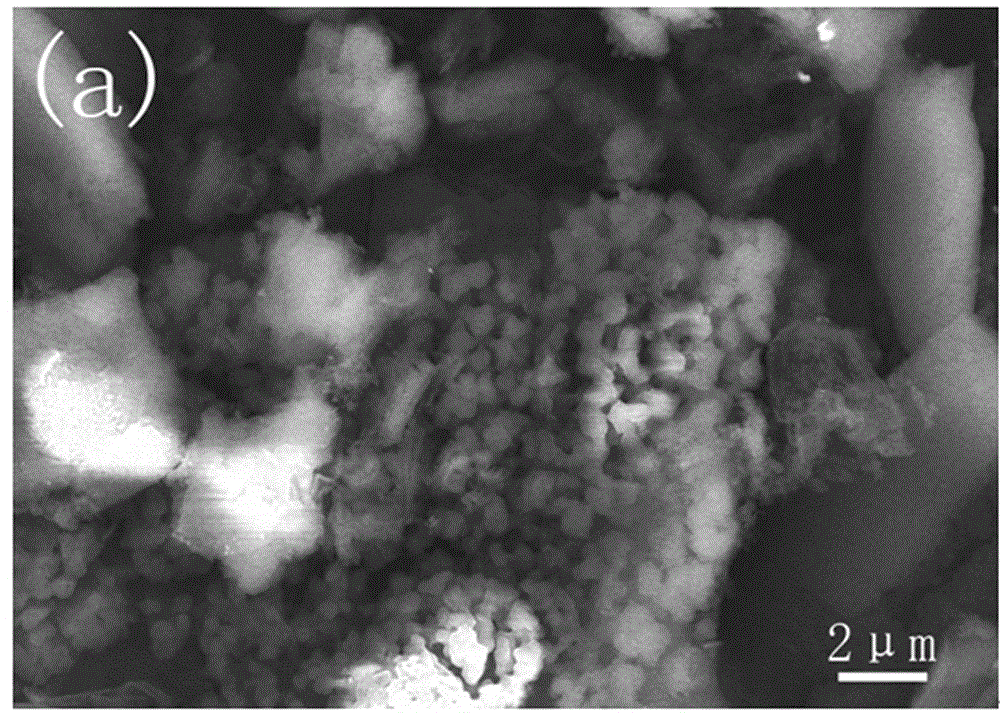

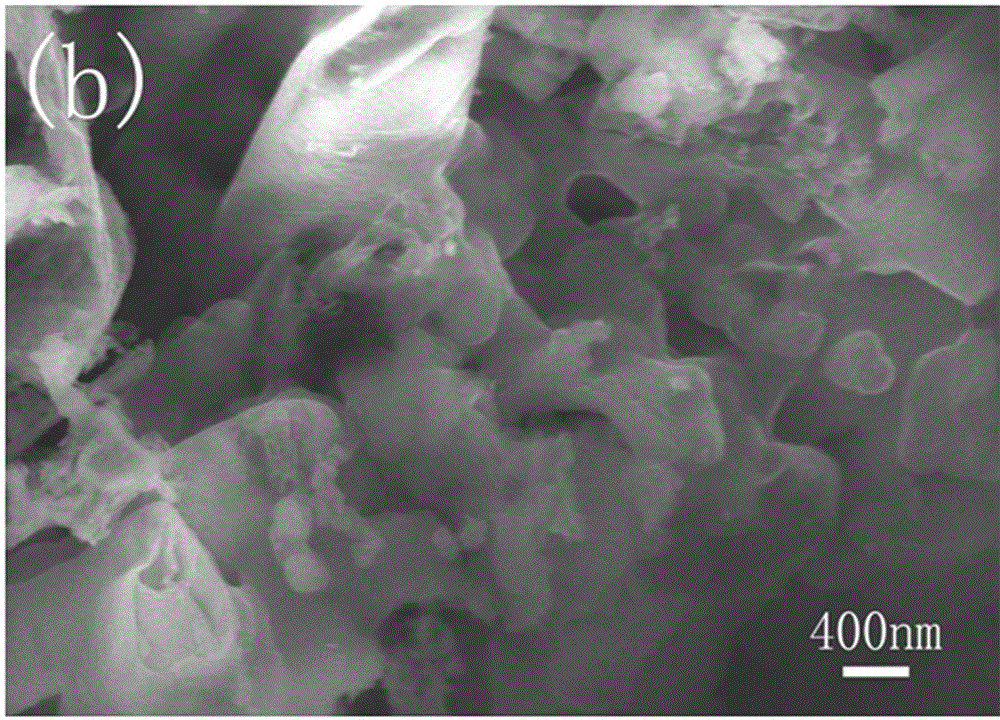

[0023] Take a certain amount of melamine and put it into a crucible, calcinate it at a temperature of 550°C for 4 hours, and grind the product finely in an agate mortar after cooling with the furnace to obtain yellow C 3 N 4 solid powder. Add 0.3g of phosphotungstic acid to the mixture of 25ml of water and 25ml of ethanol, stir for 1h, add 0.6g of carbon nitride, and continue stirring for 1h. The precipitate was separated by centrifugation and washed 3 times with deionized water and absolute ethanol. After drying in a drying oven at 100°C for 4 hours, a composite photocatalyst of phosphotungstic acid and carbon nitride can be obtained. The yield of the composite photocatalyst was 98%.

Embodiment 2

[0025] Take a certain amount of melamine and put it into a crucible, calcinate it at a temperature of 550°C for 4 hours, and grind the product finely in an agate mortar after cooling with the furnace to obtain yellow C 3 N 4 solid powder. Add 0.35g of phosphotungstic acid to the mixture of 25ml of water and 25ml of ethanol, stir for 1h, add 0.6g of carbon nitride, and continue stirring for 1h. The precipitate was separated by centrifugation and washed 3 times with deionized water and absolute ethanol. After drying in a drying oven at 100°C for 4 hours, a composite photocatalyst of phosphotungstic acid and carbon nitride can be obtained. The yield of the composite photocatalyst was 99%.

Embodiment 3

[0027] Take a certain amount of melamine and put it into a crucible, calcinate it at a temperature of 550°C for 4 hours, and grind the product finely in an agate mortar after cooling with the furnace to obtain yellow C 3 N 4 solid powder. Add 0.4g of phosphotungstic acid to the mixture of 25ml of water and 25ml of ethanol, stir for 1h, add 0.6g of carbon nitride, and continue stirring for 1h. The precipitate was separated by centrifugation and washed 3 times with deionized water and absolute ethanol. After drying in a drying oven at 100°C for 4 hours, a composite photocatalyst of phosphotungstic acid and carbon nitride can be obtained. The yield of the composite photocatalyst was 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com