Rhenium and iridium engine combustion chamber inner wall protective platinum and rhodium ring production method

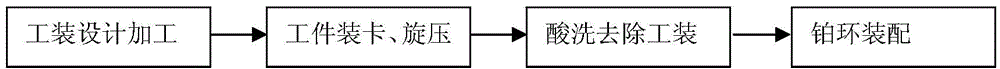

An engine and combustion chamber technology, which is applied in the field of preparing platinum-rhodium rings for inner wall protection of a rhenium-iridium engine combustion chamber, can solve problems such as thrust chamber failure and iridium coating failure, and achieve the effects of preventing corrosion, having good surface condition and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

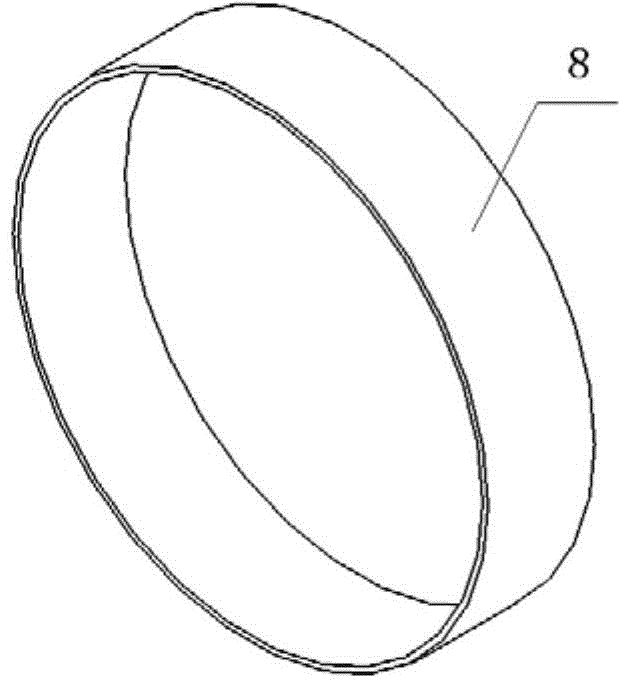

[0057] 1. Preparation of tube blanks: figure 2 As shown, the market purchases PtRh10 tubes with a thickness of 0.7mm, a length of 10mm, and an outer diameter of Ф44.6mm.

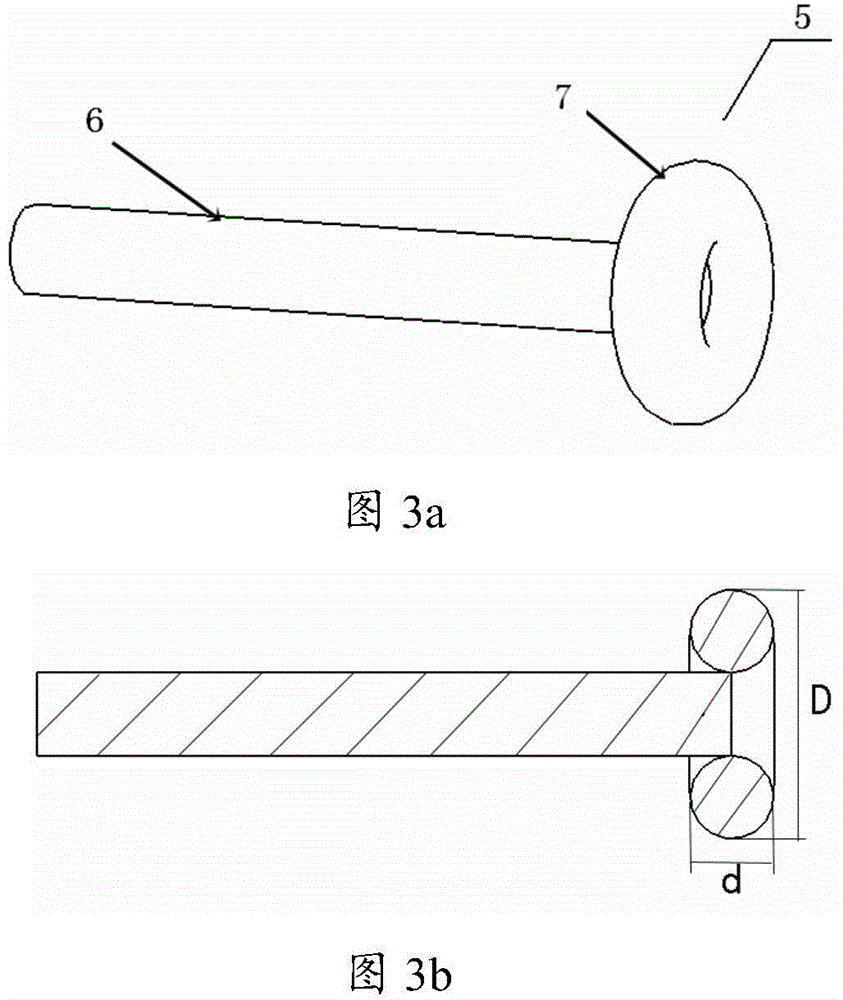

[0058] 2. The spinning process is realized on an ordinary lathe, and the diameter of the designed and processed spinning wheel 5 is D=Ф15mm, d=Ф6mm, such as image 3 .

[0059] 3. Tooling design and processing

[0060] 1. Preparation of the first spinning tooling assembly 1

[0061] (1), choose 45# high carbon steel bar material: the outer diameter is Ф60mm, the length is 50mm;

[0062] (2) Take the inner diameter of the combustion chamber product to be assembled as the inner diameter, Ф56mm as the outer diameter, and 40mm as the length to process the bar material selected in step (1), and process the assembly steps that change with the inner shape of the product.

[0063] (3), on the basis of the completion of step (2), four M3 threaded holes 3 with a depth of 10mm are processed on the end surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com