Semi-Solid Manufacturing Process of Radial-Axial Rolling Strain-Induced Method for Large Rings

An axial rolling, strain-induced technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem of large-scale casting and forming of large rings with coarse grains, inefficient, low-cost manufacturing requirements, and uneven microstructure distribution. and other problems, to achieve the effect of good mechanical properties of the product, small microstructure and grains, and enlarged inner and outer diameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

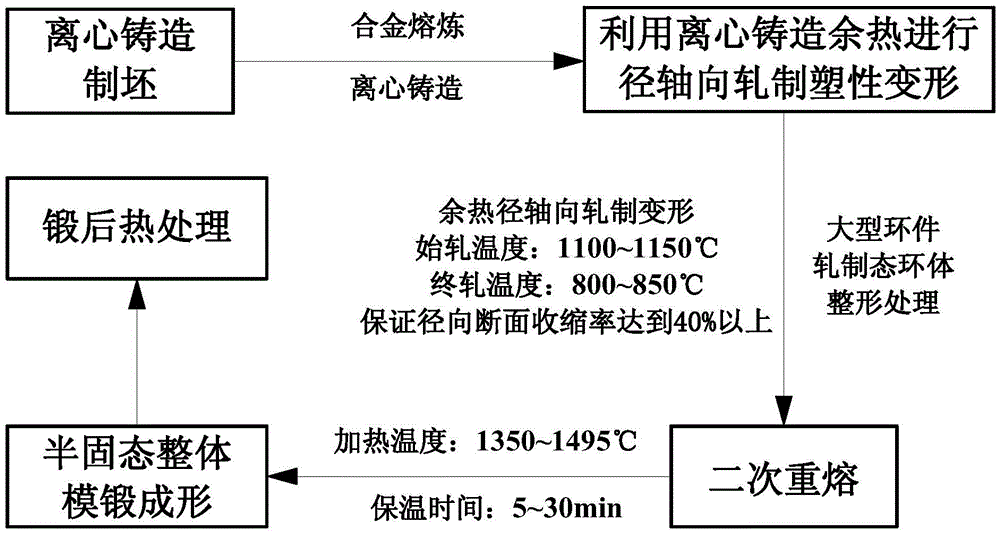

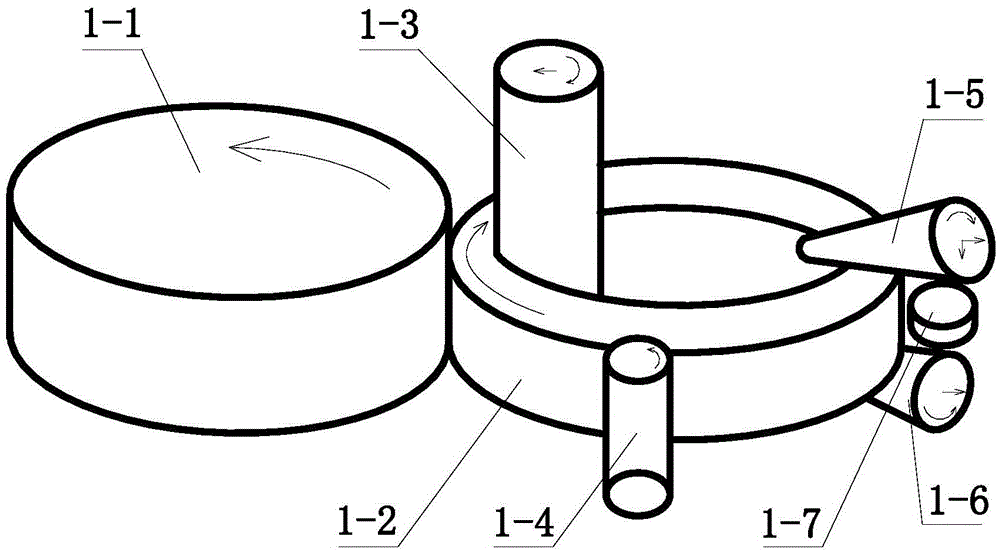

[0022] refer to figure 1 , a semi-solid manufacturing process of radial-axial rolling strain-induced method for large rings, including the following steps:

[0023] 1) Centrifugal casting billet: first, put the prepared 45# steel material into the medium frequency induction melting furnace for melting, the melting temperature is above 1600 ℃, and keep it warm for 10-20 minutes for refining and degassing; then the obtained molten steel The temperature is stably controlled at 1500-1550°C and poured into the centrifugal casting equipment, and the as-cast ring body of the large ring is prepared by the centrifugal casting process;

[0024] 2) Radial and axial rolling plastic deformation by using the residual heat of centrifugal casting: the as-cast ring body of the large ring obtained in step 1) undergoes plastic deformation with a large amount of deformation through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com