Water cooled centrifugal machine of pipe die sleeve applied to long tube drawing/heating grating system

A water-cooled centrifuge and pouring system technology, applied in the field of metal casting, can solve the problems of low equipment utilization, difficult lubrication of wheels, and affecting productivity, etc., and achieve the effect of increasing equipment utilization, uniform pipe wall thickness, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

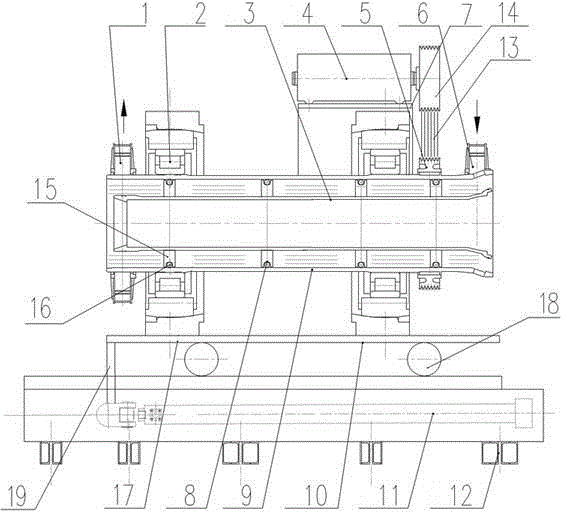

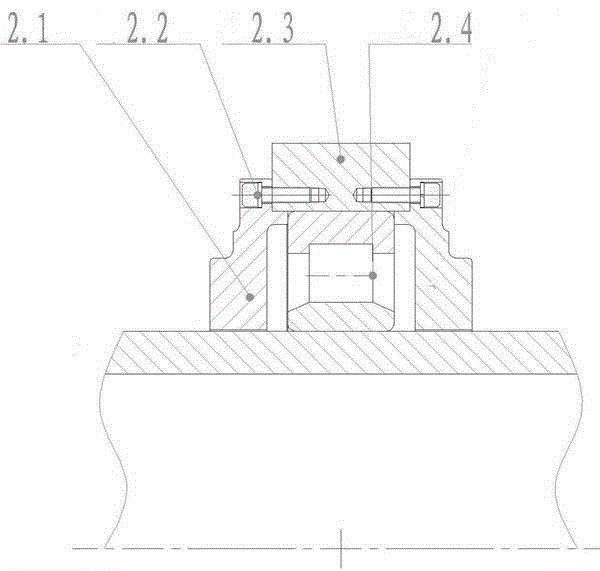

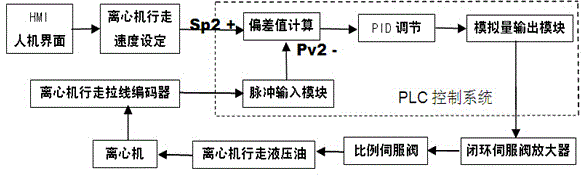

[0023] Such as Figure 1-3 As shown in the figure, a water-cooled centrifuge with pipe mold cover for long-drawn pipe\heating pouring system, the centrifuge controller is Siemens S7-300 / 400 PLC programmable controller from Germany, and the operator panel is Siemens HMI man-machine interface from Germany , HMI and PLC realize man-machine communication, process parameter setting, fault alarm and display. The CPU of the PLC programmable controller is 6ES7 300 / 400 series, with 2 MPI / PROFIBUS-DP, PROFIBUS-DP master station interfaces, one is used to connect with HMI, and the other is used to connect with the slave station. The pulse input module selects a positioning template with a high clock pulse rate that drives a servo or a stepper motor. Analog quantity output module chooses 6ES7 300 / 400 series. Both the proportional servo valve and the amplifier of the servo valve use tubes from BOSCH-REXROTH of Germany. The BOSCH-REXROTH valve has high frequency response and high control ...

Embodiment 2

[0034] Such as Figure 1-3 As shown, the working process of a water-cooled centrifuge with pipe mold cover for long-drawn pipe\heating pouring system is as follows: Step 1: Set the linear speed sp2 of each stage of the centrifuge on the man-machine interface, and pass the MPI / PROFIBUS -DP bus or Ethernet transmits the data to the controller of the PLC control system, and the pulse number pv2 of the cable encoder that detects the walking distance of the centrifuge is transmitted to the pulse input module of the PLC, and the PLC calculates the deviation value between sp2 and pv2 to perform PID adjustment, the output value is transmitted to the closed-loop servo amplifier through the analog output module, and the amplifier controls the opening of the proportional servo valve to control the walking speed of the main cylinder of the centrifuge. Among them, the linear speed sp2 takes the production of DN100 pipe as an example; when casting different parts of each pipe, the change of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com