A kind of alxga1-xn nanowire array and its preparation method and application

A technology of nanowire array and carbon cloth, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of moderate density, uniform length and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

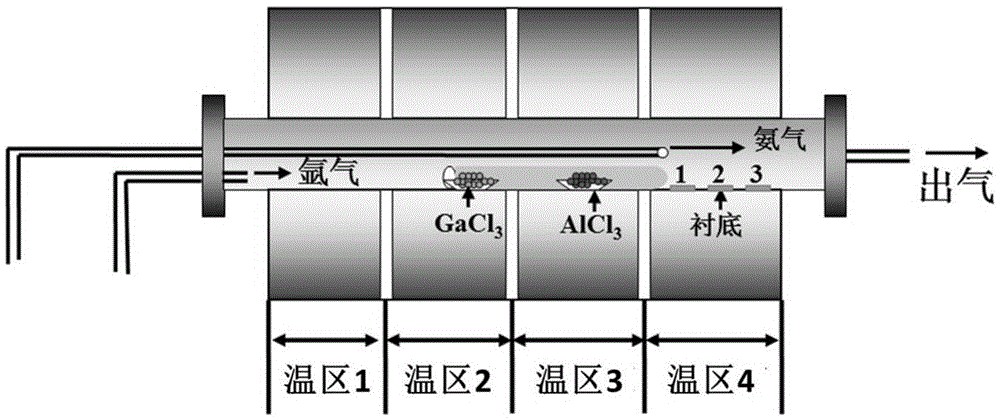

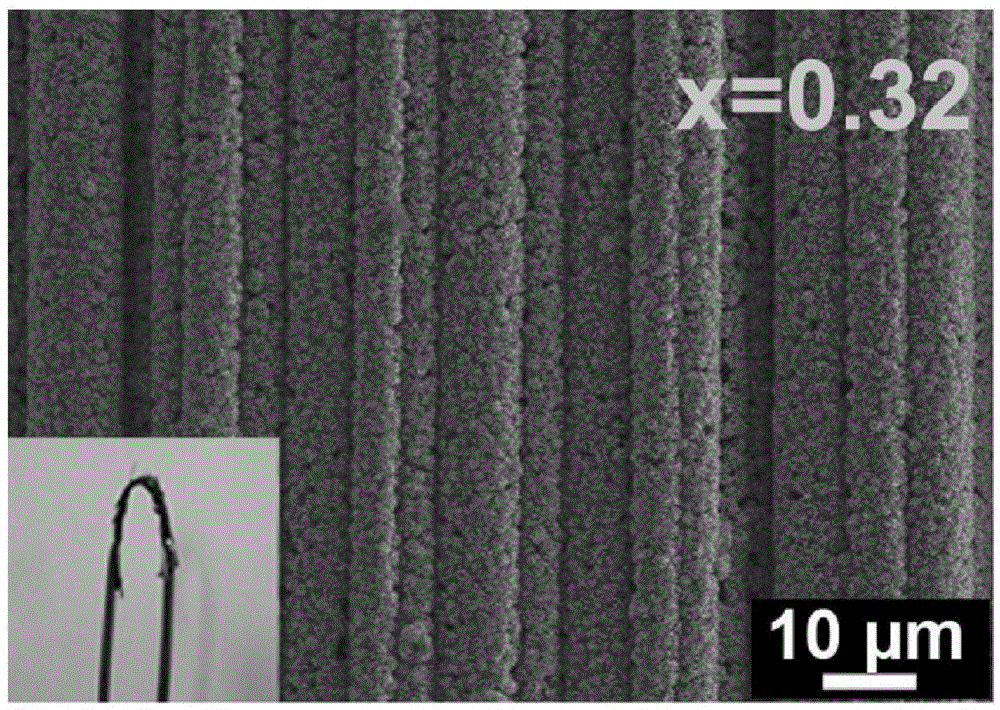

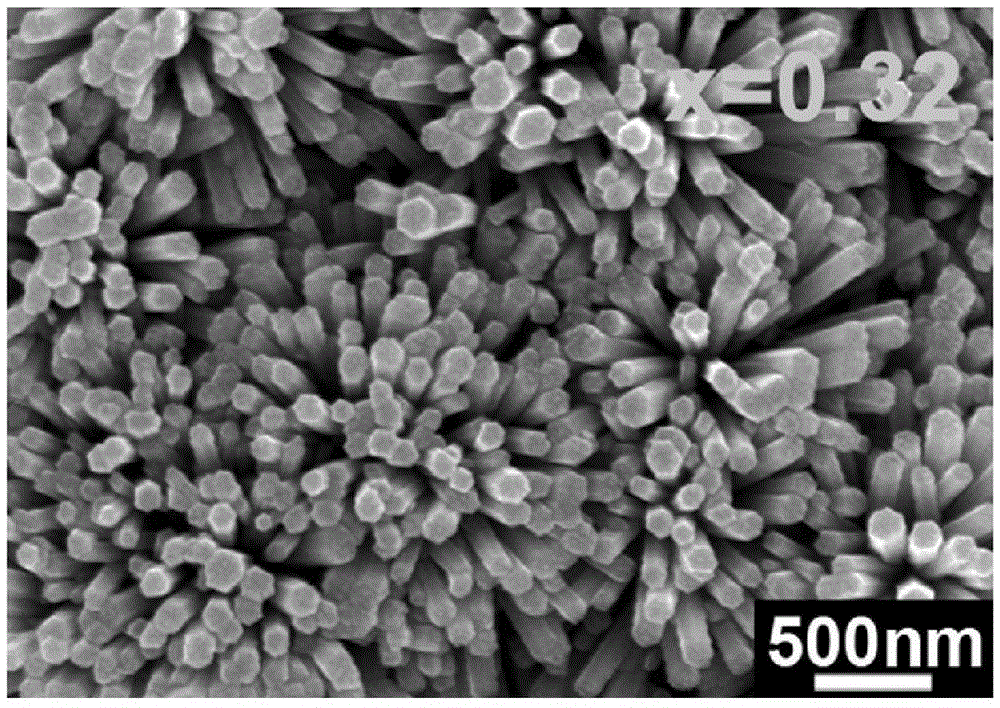

[0058] a kind of Al x Ga 1-x N nanowire arrays, using chemical vapor deposition, with carbon cloth as a flexible substrate, AlCl 3 as aluminum source, GaCl 3 It is prepared by reacting gallium source with ammonia gas as nitrogen source. Its preparation is carried out in a horizontal tube furnace with four temperature zones, and the schematic diagram of the device is shown in figure 1 Shown, specifically comprise following preparation steps:

[0059] (1) Choose a carbon cloth that does not contain a catalyst and a seed layer. The size of the carbon cloth is 1cm×4cm. Immerse the carbon cloth in an alcohol solution for 10 minutes, then rinse it with deionized water for 3 times, and finally keep it warm in an oven at 100°C. 1 hour to dry for later use;

[0060] (2) 0.4 g of AlCl 3 with 0.4 g GaCl 3 respectively placed in two quartz boats;

[0061] (3) For the four-temperature-zone horizontal tube furnace, the three-stage temperature zone close to the gas outlet is set as t...

Embodiment 2

[0068] a kind of Al x Ga 1-x N nanowire arrays were prepared using the same device as in Example 1, specifically including the following preparation steps:

[0069] (1) Choose a carbon cloth that does not contain a catalyst and a seed layer. The size of the carbon cloth is 1cm×4cm. Immerse the carbon cloth in an alcohol solution for 10 minutes, then rinse it with deionized water for 3 times, and finally keep it warm in an oven at 100°C. 1 hour to dry for later use;

[0070] (2) 0.4 g of AlCl 3 with 0.4 g GaCl 3 respectively placed in two quartz boats;

[0071] (3) For the four-temperature-zone horizontal tube furnace, the three-stage temperature zone close to the gas outlet is set as the first temperature zone, the gallium source temperature zone, the aluminum source temperature zone and the deposition zone in sequence according to the airflow direction; GaCl will be installed 3 The quartz boat placed in the gallium source temperature zone will be filled with AlCl 3 The ...

Embodiment 3

[0076] a kind of Al x Ga 1-x N nanowire arrays were prepared using the same device as in Example 1, specifically including the following preparation steps:

[0077] (1) Choose a carbon cloth that does not contain a catalyst and a seed layer. The size of the carbon cloth is 1cm×4cm. Immerse the carbon cloth in an alcohol solution for 10 minutes, then rinse it with deionized water for 3 times, and finally keep it warm in an oven at 100°C. 1 hour to dry for later use;

[0078] (2) 0.4 g of AlCl 3 with 0.4 g GaCl 3 respectively placed in two quartz boats;

[0079] (3) For the four-temperature-zone horizontal tube furnace, the three-stage temperature zone close to the gas outlet is set as the first temperature zone, the gallium source temperature zone, the aluminum source temperature zone and the deposition zone in sequence according to the airflow direction; GaCl will be installed 3 The quartz boat placed in the gallium source temperature zone will be filled with AlCl 3 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com