A kind of retarding cement grinding aid and preparation method thereof

A cement grinding aid and retarding technology, which is applied in the field of cement admixtures, can solve problems such as difficulty in achieving grinding aid effects, poor adsorption and dispersion effects, and unstable effects, so as to optimize particle gradation and delay coagulation Time, the effect of prolonging the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 (No. DE-1):

[0022] A slow-setting cement grinding aid is composed of 20% modified diethanolamine mother liquor, 8% glycerol, 5% sodium sulfate, 67% water, and the total amount is 100%.

[0023] The preparation process of the retarded cement grinding aid has the following steps:

[0024] a. Take by weighing 21.1g diethanolamine and 9.2g epichlorohydrin, add diethanolamine in a three-necked flask with a stirring device, and add epichlorohydrin in a constant pressure dropper for subsequent use; weigh 10g of 40% NaOH aqueous solution, Add it into another constant pressure dropper, open two constant pressure droppers at the same time, slowly drop and stir to control the reaction temperature; after the drop is complete, react for another 1.5 hours;

[0025] b. Pour the reaction product of step a into a beaker and place it in a vacuum drying oven, evaporate the moisture therein, separate out NaCl, and take the supernatant to obtain the modified diethanolamine m...

Embodiment 2~6

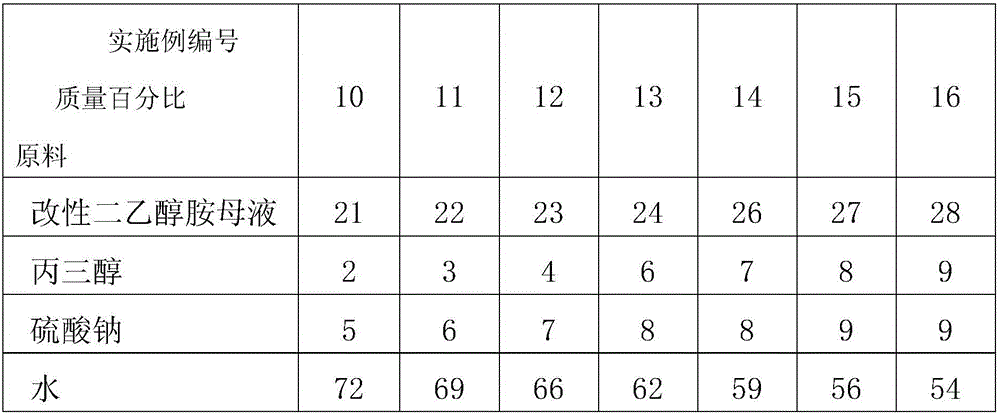

[0028] According to the proportioning in Table 1, adjust the consumption of modified diethanolamine mother liquor, glycerin, sodium sulfate and water, and prepare five kinds of retarded grinding aids of embodiment number DE-2~DE-6:

[0029] Table 1 Raw material ratio of Examples 1-6

[0030] Numbering

Embodiment 1~6

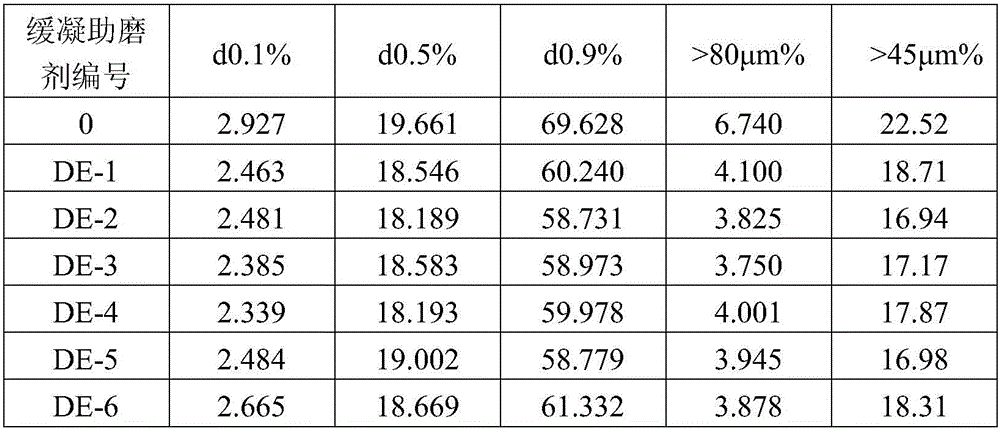

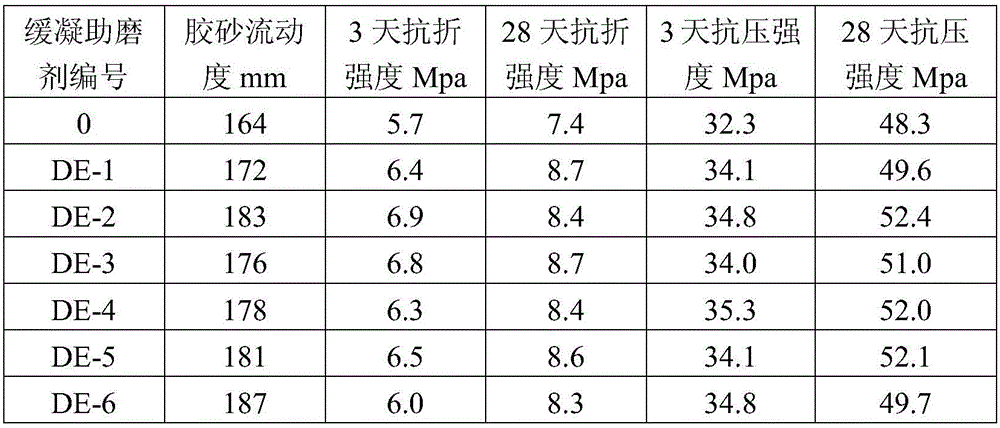

[0031] The retarded grinding aids obtained in Examples 1 to 6 (numbering DE-1 to DE-6) were subjected to a small grinding test.

[0032] The cement clinker and gypsum used in the test are all from a cement factory in Jiangyou, Sichuan, and their chemical composition and mass percentage content are shown in Table 2 below (the total amount is 100%, and the remaining mass percentage content is loss on ignition):

[0033] Table 2 Chemical composition of clinker and gypsum

[0034] Element

SiO 2

al 2 o 3

Fe2O 3

CaO

MgO

SO 3

clinker%

0.71

19.04

5.62

3.39

63.23

1.92

0.90

plaster%

8.65

1.70

0.30

0.20

38.41

0.80

48.63

[0035] Use a jaw crusher to crush the clinker and gypsum with a mass ratio of 95:5 to less than 5mm, weigh 5kg of raw materials, drop the weighed retarding grinding aid evenly on the raw materials, and then pour the raw materials into φ500mm×500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com